Automatic Packing Machine CKB-180K

Automatic Packing Machine CKB-180K

CKB-180K is a highly automated combination packaging machine designed for the food and pharmaceutical industries, suitable for efficient packaging of boxed products. The machine integrates advanced technology with humanized operation design to ensure stable and reliable operation performance. The use of imported electronic components, PLC control system and human-machine interface (HMI) not only ensures the high precision and durability of the equipment, but also provides a simple and friendly user interaction experience.

CKB-180K automatic packaging machine is known for its efficient automation level, stable operation performance, flexible adaptation to multiple specifications and fine mechanical adjustment functions, aiming to help companies improve production efficiency and ensure product quality consistency. Its built-in safety protection measures, including emergency stop buttons and protective doors, ensure the safety of operators while ensuring the normal operation of the machine. In summary, CKB-180K is not only an efficient packaging solution, but also an intelligent, reliable and high-value-added production partner, committed to providing users with an excellent packaging experience and helping companies stand out in the fiercely competitive market environment.

Description

The CKB-180K is a highly efficient automatic packing machine designed for the combined packing of boxed products in the food and pharmaceutical industries. Featuring imported electronic components, a PLC control system, and an HMI, it ensures stable and reliable operation with user-friendly functionality.

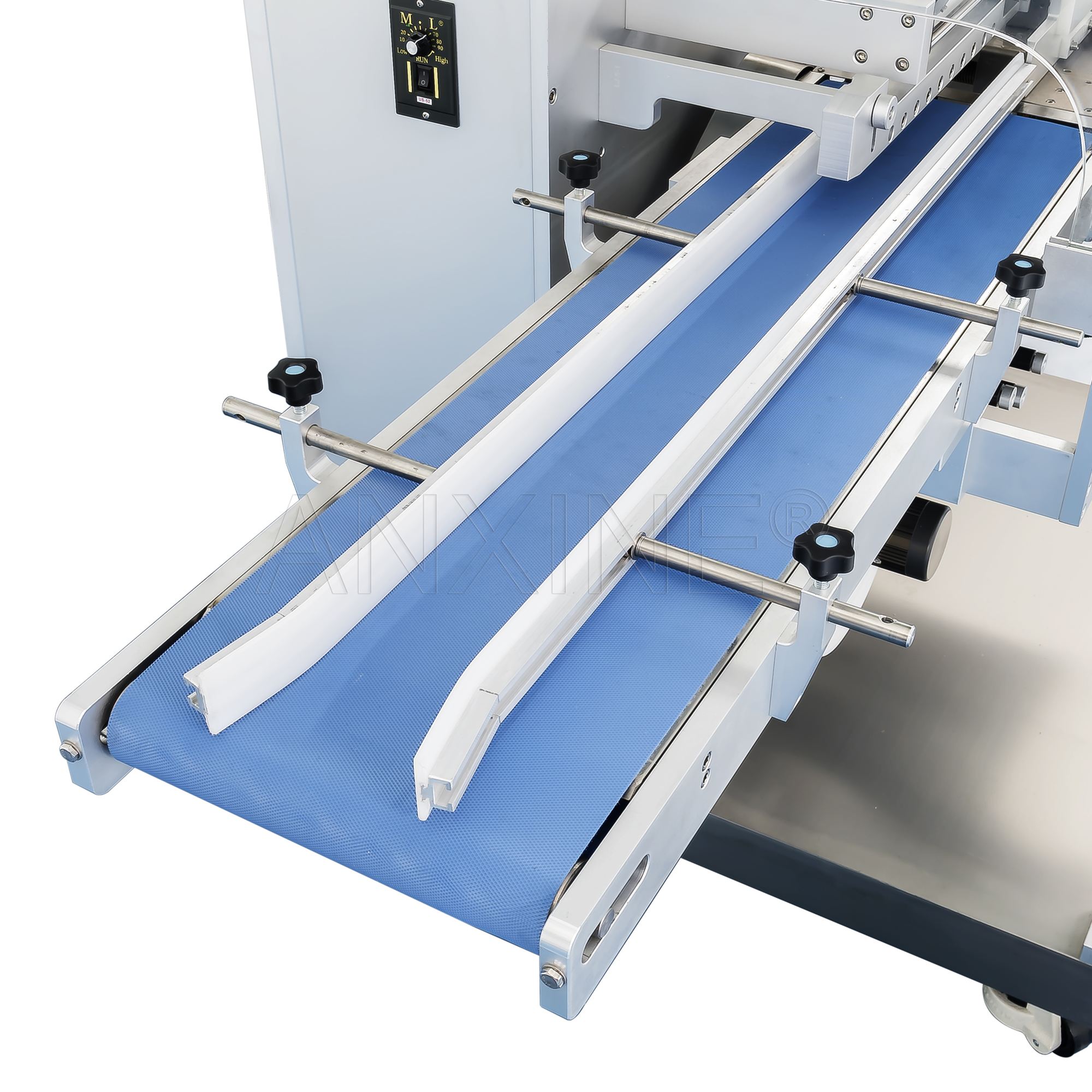

The machine’s box-conveying mechanism guides boxes to an optical fiber sensor. Once detected, a box-loading cylinder pushes the boxes into a storage rack. After reaching the set quantity, a box-pushing cylinder moves the batch to the heat-seal mechanism for sealing, cutting, and cooling. The process includes conveyor belt integration and servo-controlled film management.

Highlighted Features

- Application: Suitable for packing boxed products in food and pharmaceutical sectors using PE film.

- Compatibility: Can handle boxes ranging from 50x60x90mm to 240x150x300mm in size.

- Packing Speed: Capable of packing 8-15 bales per minute, depending on box size and layers.

- Technology: Equipped with precision PLC control and imported electronic components for enhanced reliability.

- Power: Conveyor motor power of 120W using synchronous belt transmission ensures efficient operation.

- Advanced Mechanisms:Built-in optical fiber guides the box-loading process;Heat-seal mechanism features both upper and lower sealing functions;PLC issues signals to coordinate box movements and sealing processes.

Specifications

| Model | CKB-180K |

|---|---|

| Packing Size | Maximum: 240 x 150 x 300 mm Minimum: 50 x 60 x 90 mm |

| Packing Material | PE film |

| Applicable Packing Tape Width | 30-80mm |

| Packing Film Thickness | 30-80μm |

| Packing Speed | 8-15 bales/min |

| Power | 220V/50Hz 800W |

| Dimension | 1,100 x 800 x 1,600 mm |

| Weight | 350kg |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288