Semi-Auto Plastic Tube Filling Sealing Machine CNF-30A

Semi-Auto Plastic Tube Filling Sealing Machine CNF-30A

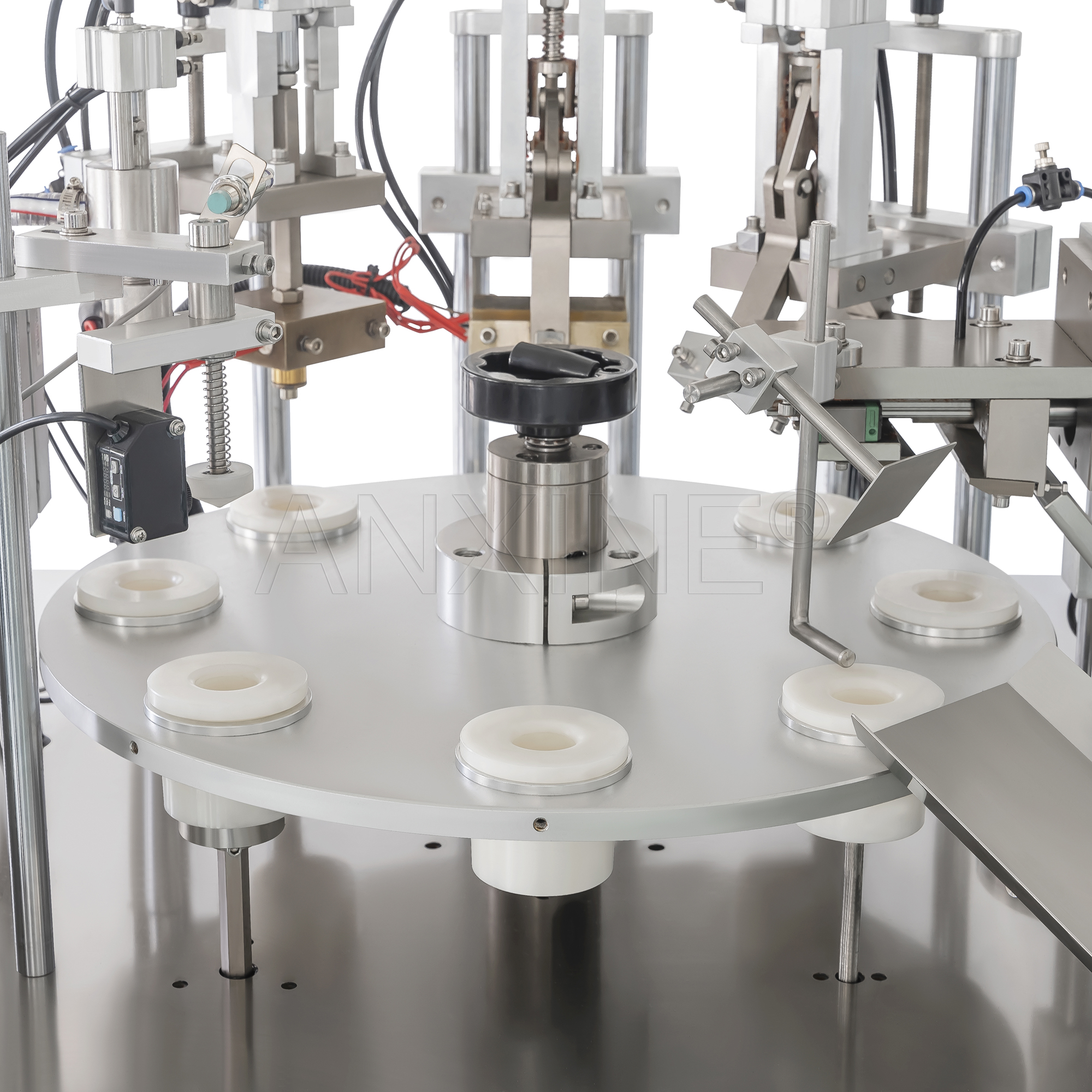

The CNF-30A plastic (composite) hose filling and sealing machine is a highly efficient automated equipment designed for the pharmaceutical, cosmetics and other industries. The machine has the functions of automatic filling, internal and external heating, end sealing, batch number printing and finished product output, ensuring the ease of operation and production efficiency.

The CNF-30A plastic (composite) hose filling and sealing machine adopts an advanced index distribution device to realize the full process automation from material filling to the final product. It has precise filling control, stable heating time adjustment ability, excellent sealing effect, and supports customized production batch number printing. The whole machine works stably and reliably, without noise and other pollution. All parts in contact with the material are made of high-quality stainless steel, which is easy to clean and maintain. For materials that need to be kept warm, the external barrel can also be installed with a heating and heat preservation device. This machine has 10 stations that can work simultaneously, which can meet the production needs of enterprises of different sizes.

Description

The CNF-30A Plastic Tube Filling and Sealing Machine encapsulates the essence of efficient, reliable, and clean operations. Featuring an indexing device, the machine automates a series of tasks, including filling, interior and exterior heating, end-sealing, batch number printing, and product output. The design accommodates up to ten tubes that can be filled and sealed, making it a staple for high-output productivity across various industries. This machine maintains a noise- and pollution-free operation along with accurate filling, controllable heating time, and superior sealing results.

Highlighted Features

- All material-contacting parts are made from 316L stainless steel for hygiene and longevity.

- The components are connected using quick-assembly, facilitating easy disassembly for cleaning.

- Equipped with high-quality pneumatic components and an air-blowing device at the tail cutting section to prevent any material buildup.

- The machine is powered by a motor, running through a worm gear reducer with variable frequency speed regulation. The isometric movement ensures equal strokes for each fixture between positions.

Specifications

| Model | CNF-30A |

|---|---|

| Filling Capacity | 0~250 ml |

| Production Capacity | 0-20 pcs/min |

| Power Supply | ~220V±10% |

| Power | 0~250 ml |

| Dimensions | 1,200 x 800 x 1,450 mm |

| Weight | 350kg |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288