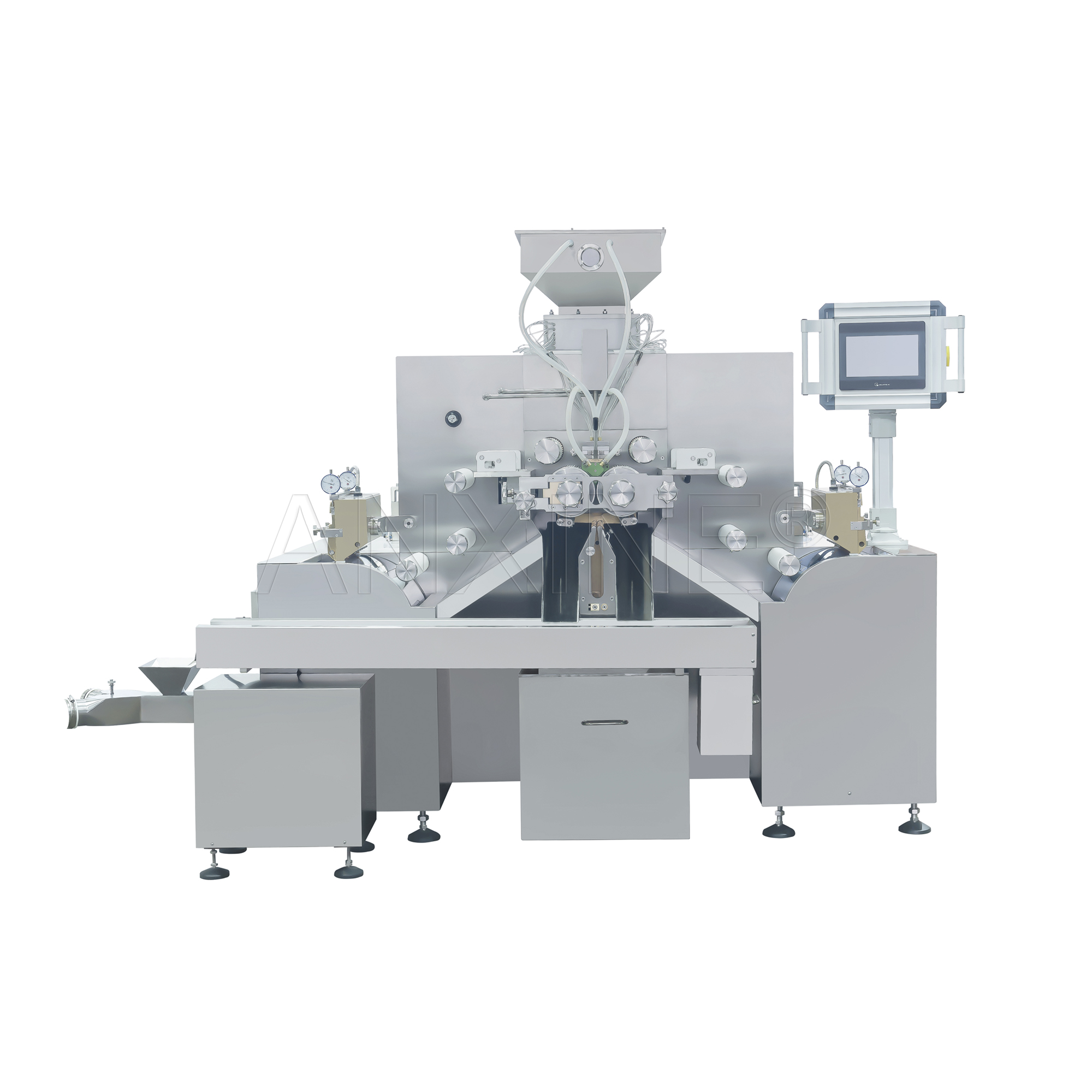

Advanced Softgel Capsule Filling Machine ASE-300C

Liquid R&D Softgel Capsule Gel Oil Filling Machine ASE-300C

The ASE-300C is an advanced softgel encapsulation machine designed for high efficiency, precision, and versatility in the production of softgel capsules. Constructed with durable components including a machine base, body, head, feeding and oil rolling systems, pill lowering device, spreading box, and lubrication system, this machine ensures reliable operation. Its features such as stepless speed regulation enabled by the built-in motor and frequency converter, along with a robust gear and worm gear transmission system, facilitate optimal power distribution and operational flexibility.

Capable of handling oils, suspensions, and pasty materials, the ASE-300C can produce a wide range of softgels varying in size, shape, and color, which are appreciated for their quick disintegration, ease of use, oxidation resistance, and easy storage. This machine’s productivity, accuracy, and stability make it suitable for various industries including pharmaceuticals, health supplements, and cosmetics.

Description

The ASE-300C is a state-of-the-art softgel encapsulation machine designed for high efficiency and precision in capsule production. It features a robust construction with components such as a machine base, body, machine head, feeding system, oil rolling system, pill lowering device, spreading box, and lubrication system. The built-in motor and frequency converter allow for stepless speed regulation, while the gear and worm gear transmission system ensure power distribution to all components.

Highlighted Features

- High Production Capacity: Capable of producing up to 370 million granules annually (based on 200C model, No.8 oval shape, 3rpm, 24 hours/day, 300 days/year).

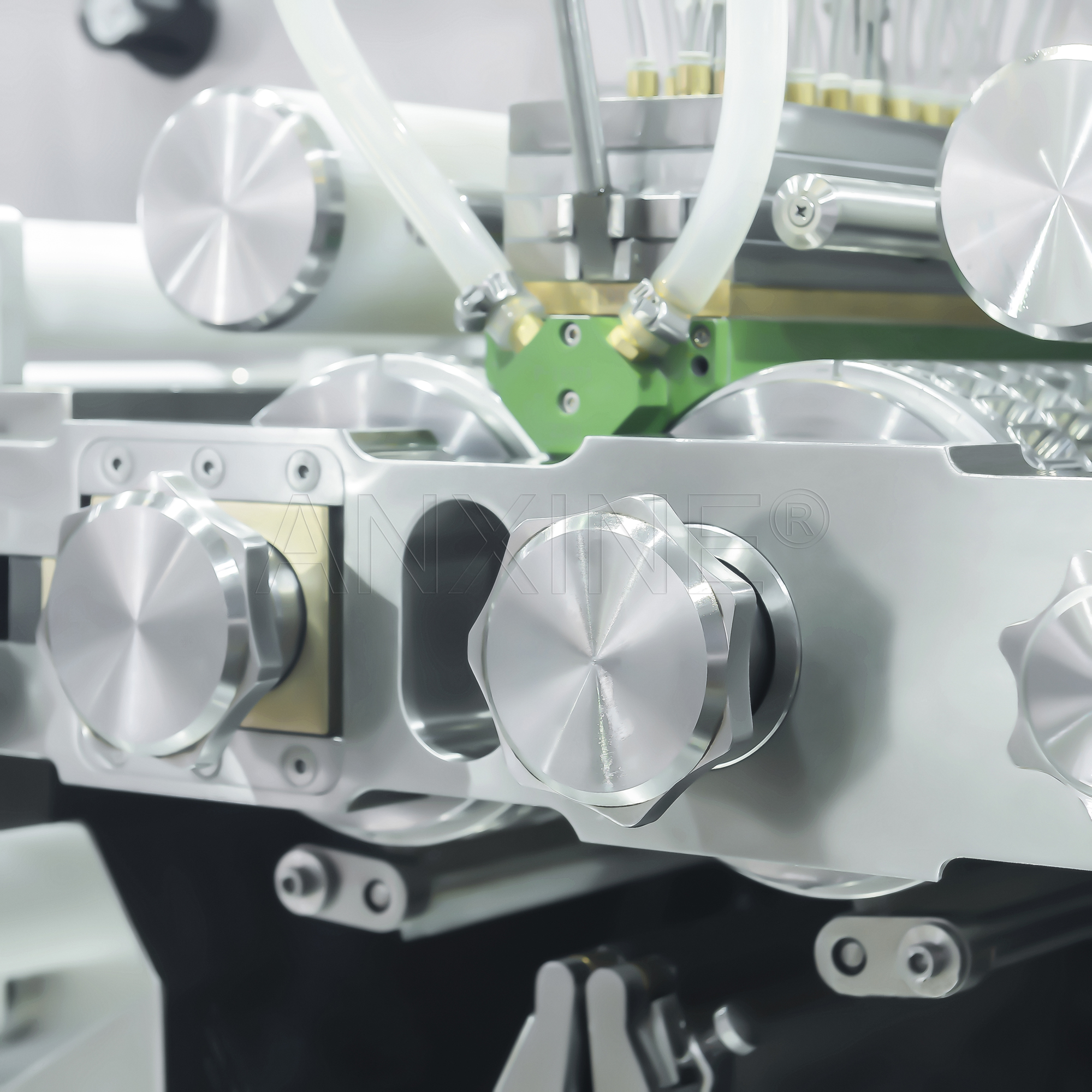

- Precision Medicine Injection: Utilizes an advanced linear driving system to ensure charging and filling precision within 2%.

- Efficient Cooling System: Features a water cooling system to prevent air pollution.

- High Capsule Package Rate: Achieves a package rate of up to 98%.

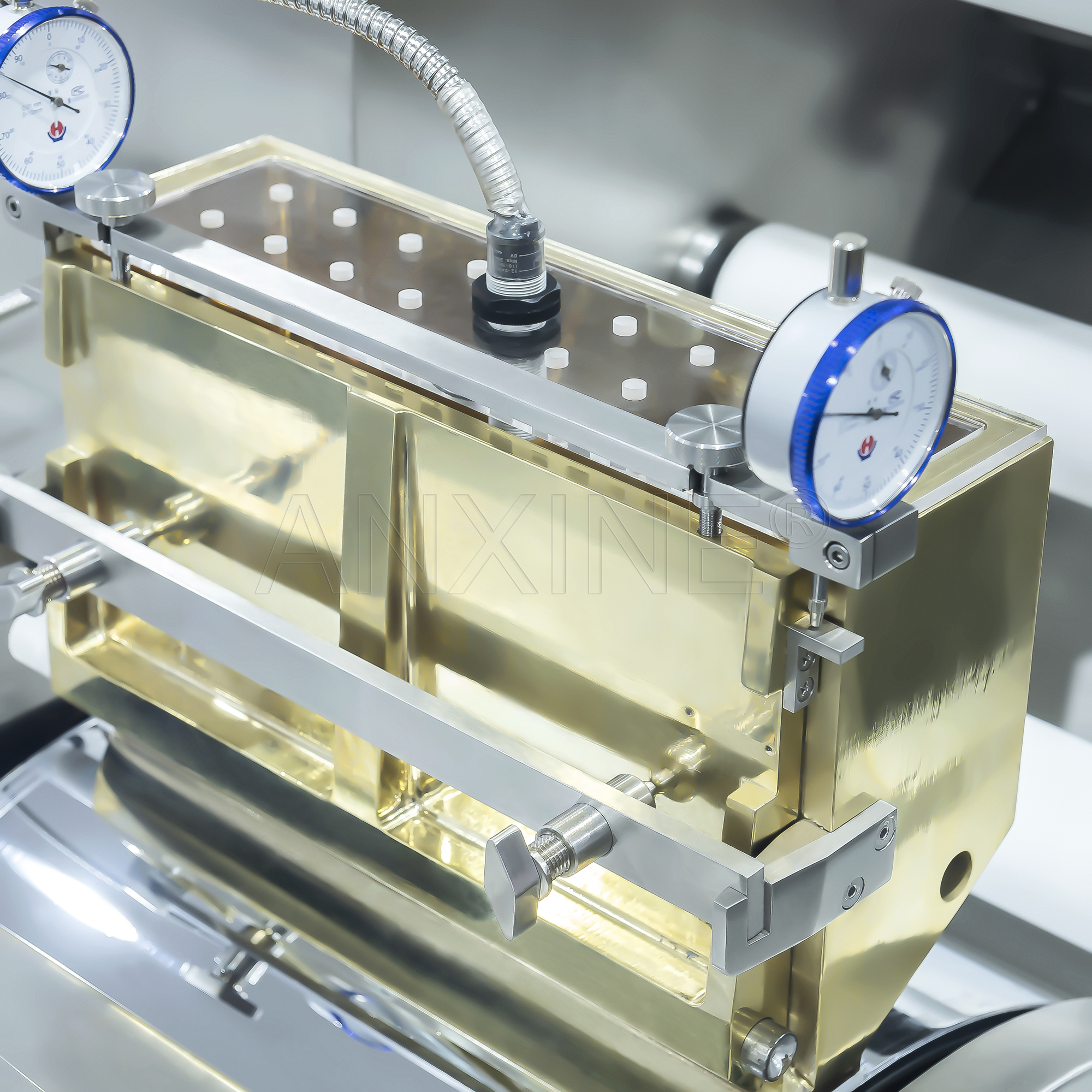

- Optimized Lubrication: Fine oil supply technology reduces lubrication oil consumption, with the option to use vegetable oil for wash-free capsules.

- FDA-Approved Conveyor Belt: Ensures safety and ease of cleaning.

- Durable Mould Design: Made from high-quality aviation alloy for extended service life.

- Automated Systems: Reduces labor intensity and improves the working environment, meeting GMP standards.

- Consistent Gelatin Level: Automatic control maintains a constant gelatin level, with easy thickness adjustments.

Specifications

| Model | ASE-300C |

|---|---|

| Mould Rotational Speed | 0-5 rpm (Stepless frequency speed control) |

| Control System | Omron PLC + Weinview touch screen |

| Capacity | Approximately 70,200 pills/hour for 8# Oval at medium speed |

| Supplying Volume | 0-2ml per single-pillar stopper |

| Pillar Quantity | 24 |

| Glue Cooling | Water cooling at approximately 18℃ |

| Power | 16.5 kW |

| Dimensions | 2200×1275×1900 mm |

| Weight | 1580 kg |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288