Automatic Continuous Mill Herb Grinder WF Series

Automatic Continuous Mill Herb Grinder WF Series

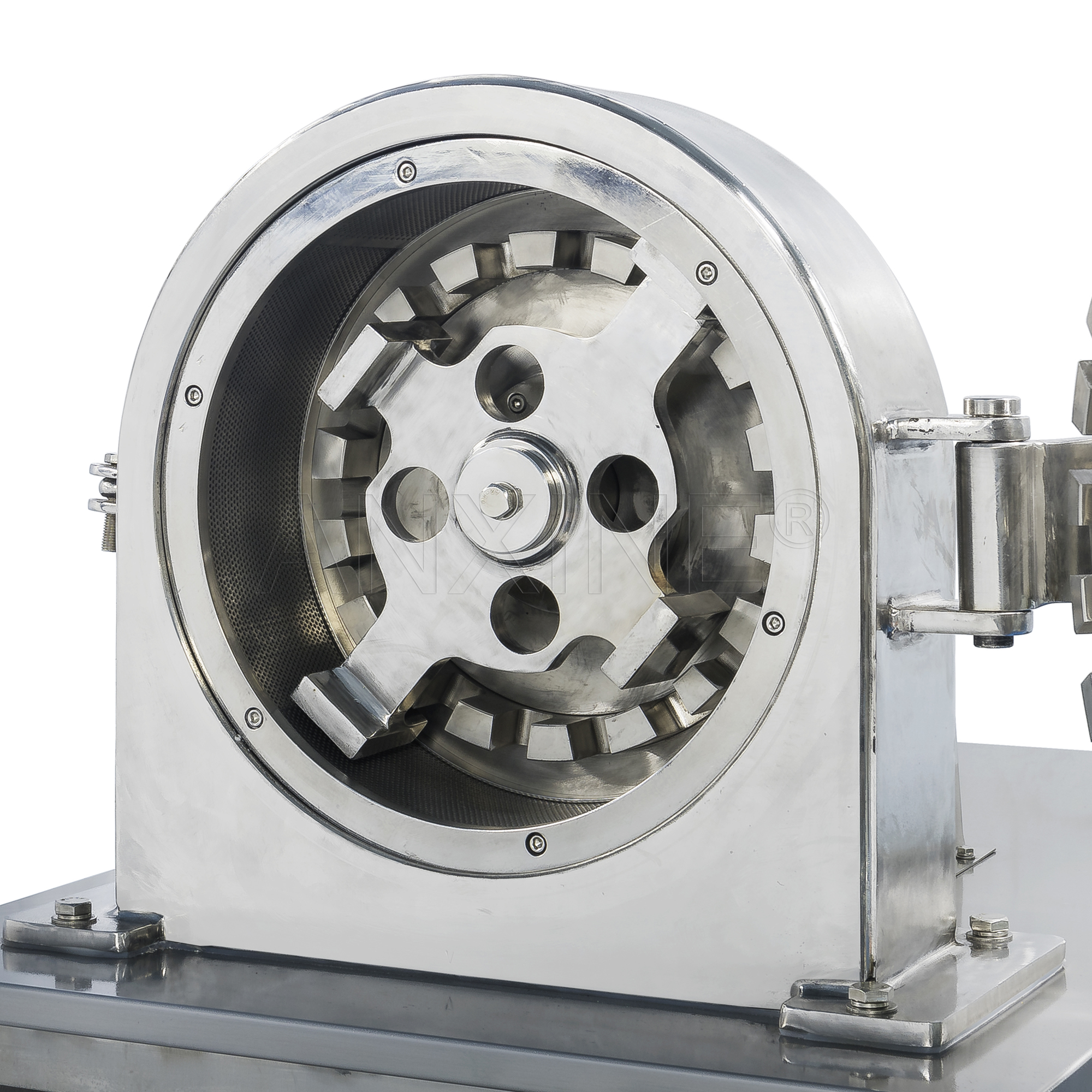

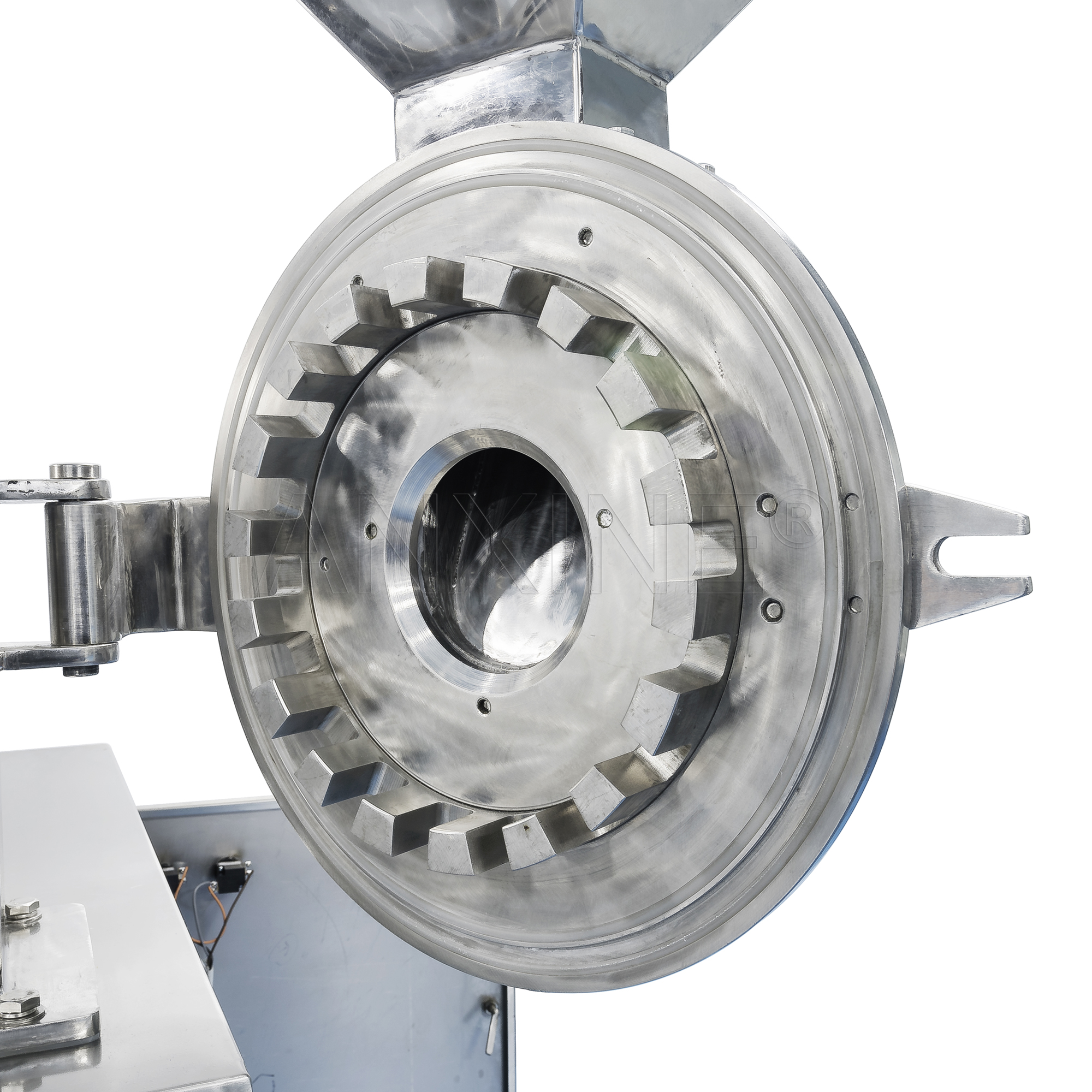

The The WF Series granulators are engineered for the efficient and hygienic grinding of dry, free-flowing, and heat-sensitive materials to a fine 120 mesh with a narrow particle size distribution, ideal for substances like resins and sugar. These granulators boast an innovative design that facilitates easy maintenance and cleaning, operate at high speeds ranging from 3400 to 7000 rpm for rapid processing, and offer versatile applications across the food, herbal products, chemical, and spice industries.

With customizable screen apertures from 0.4mm to 3.0mm, users can achieve precise control over the final product size, making these granulators suitable for processing a wide range of materials including sesame seeds, walnuts, herbs like ginseng and cinnamon, chemicals such as coal and salt, and spices like pepper and star anise.

Description

The WF Series granulators are designed to grind dry, free-flowing materials to a fine 120 mesh with a narrow particle size distribution. They are perfect for heat-sensitive materials like resins and sugar, ensuring precise, efficient, and hygienic grinding.

Highlighted Features

- Efficient Grinding: The WF Series achieves a fine and consistent particle size. The innovative design allows ease of access to internal components, simplifying maintenance and cleaning.

- High-Speed Operation: Models in the series feature rotary speeds ranging from 3400 to 7000 rpm, enabling rapid material processing.

- Versatile Applications: Suitable for various applications including food, dried herbs, chemical raw materials, and spices.

- Customizable Output: The grinder features adjustable screen apertures from 0.4mm to 3.0mm, allowing precise control over the final product size.

- Replaceable Blades: Easily swap grinding blades for continued efficiency and prolonged machine life.

- Sanitary Design: Options available for sanitary construction, ensuring the grinder meets hygiene standards.

- Precise Control: Fine-tune the finished particle size and distribution for optimal product quality.

Specifications

| Model | WF-130 | WF-180 | WF-250 | WF-320 | WF-40B |

|---|---|---|---|---|---|

| Rotary speed | 7000r/min | 4000r/min | 4000r/min | 4500r/min | 3400r/min |

| Screen aperture | 0.4mm-3.0mm | 0.4mm-3.0mm | 0.4mm-3.0mm | 0.4mm-3.0mm | 0.4mm-3.0mm |

| Capacity | 2—5kg/h | 10~20kg/h | 50~250kg/h | 80~300kg/h | 160~800kg/h |

| Material size | 5*5*5mm | 8*8*8mm | 10*10*10mm | 10*10*10mm | 12*12*12mm |

| Power | 1.1kw | 2.2kw | 4.0kw | 7.5kw | 11kw |

| Dimensions | 420*350*880mm | 420*600*1000mm | 860*500*1360mm | 880*520*1450mm | 800*900*1400mm |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288