Automatic Powder Packaging Machine VFSS-50P

Automatic Single-Row Powder Back-Sealing Packaging Machine VFSS-50P

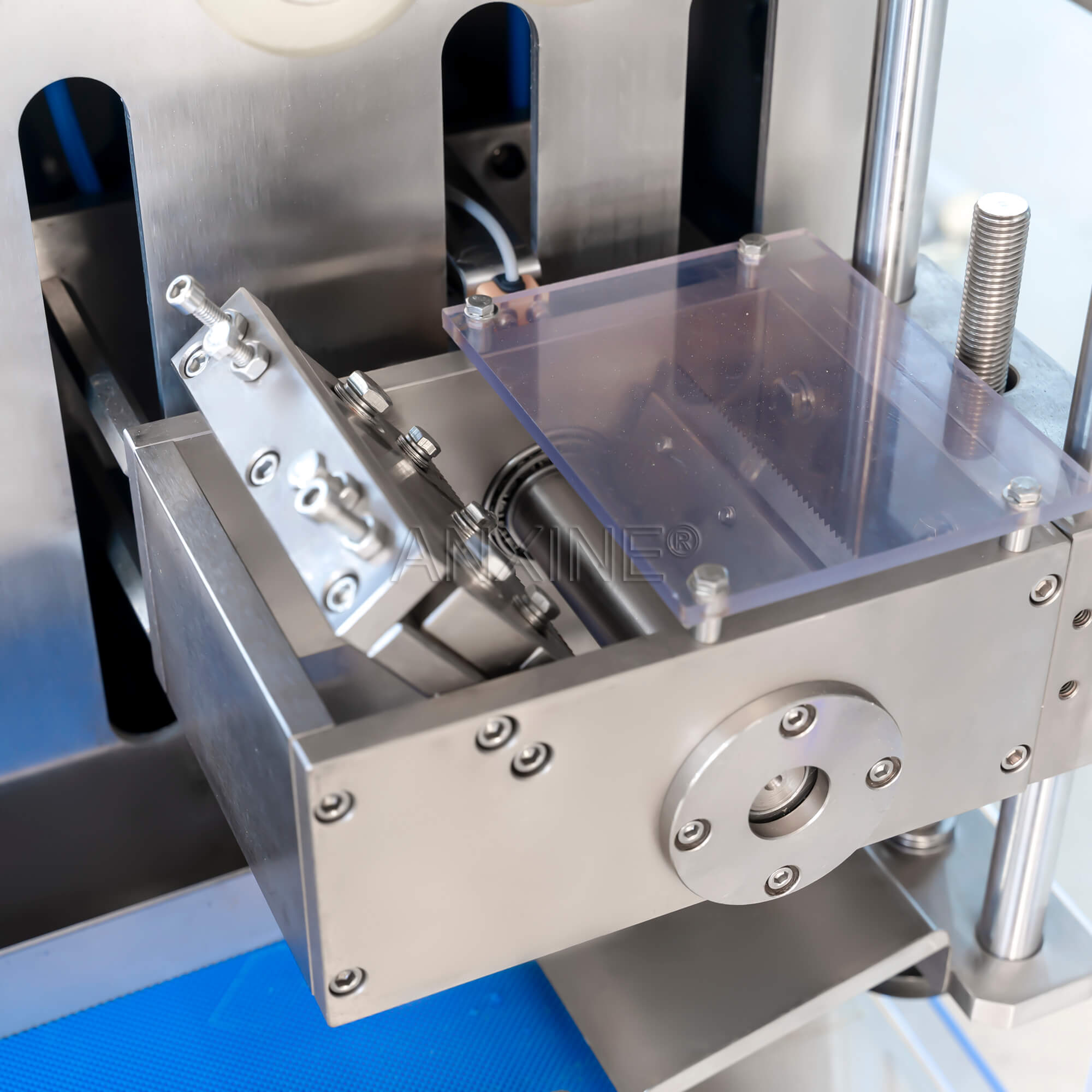

The VFSS-50P automatic single-channel powder back-seal packaging machine is a professional equipment designed for efficient and accurate packaging of powdered materials. It is suitable for pharmaceutical, food processing and other industries that require accurate metering and sealed packaging of powders. It integrates automatic feeding, metering, bag making, filling, sealing and cutting functions in one, ensuring the accurate and consistent amount of material in each bag and providing a stable and reliable production process.

The VFSS-50P automatic single-channel powder back-seal packaging machine adopts advanced technology and humanized design concepts to meet strict quality control requirements. The machine is capable of handling a variety of types of powder materials, including but not limited to pharmaceutical powders, food additives, etc. Through its precise weighing system and stable mechanical structure, the VFSS-50P can achieve fast and accurate packaging operations. In addition, the machine is equipped with a user-friendly touch screen controller, which makes parameter setting simple and fast, and provides real-time status display and monitoring functions. In order to ensure safe operation, the VFSS-50P is equipped with an emergency stop switch and multiple protection mechanisms, which can respond quickly and take appropriate measures when encountering abnormal situations. This packaging machine is also particularly suitable for small batches or medium-scale production, because of its high flexibility and can adapt to the packaging needs of products of different sizes and shapes.

Description

The CBZ-50F Automatic Single-Row Powder Back-Seal Packaging Machine is a compact vertical solution for packaging powder products. This machine integrates advanced computer control technology, automating the entire bag-making process, including metering, filling, sealing, printing the production date, tearing, cutting, and counting. Ideal for industries like food, chemical, and pharmaceutical, it’s a versatile tool for efficient production.

Highlighted Features

- Efficient Production: Fully automates bag making, filling, sealing, printing, tearing, cutting, and counting.

- Precise Control: Stepper motor-driven with adjustable bag length and speed for reliable performance.

- Automatic Detection: Photoelectric detection ensures pattern integrity and aesthetic appeal.

- Automatic Shutdown: Stops automatically when packaging material is low to prevent empty runs.

- Self-Diagnosis: Built-in diagnostics and fault indication for easy problem-solving.

- Temperature Control: High-precision PID system for quality heat sealing.

- Easy Operation: Simple, intermittent structure for ease of use and maintenance.

- Versatility: Multi-purpose packaging with interchangeable filling heads.

- Additional Functions: Optional batch number printing and tearing for convenience.

- High-Quality Components: Ensures stable performance, low noise, and long service life.

Specifications

| Model | VFSS-50P |

|---|---|

| Packaging Materials | PE, PP, PET, aluminum foil composite film, etc. |

| Packing Speed | Up to 60 bags/minute |

| Bag Size | Length: 50-200 mm, Width: 50-150 mm |

| Compressed Air | 0.6 MPa, air consumption 0.3 m³/min |

| Power Supply | AC220V/50Hz or AC110V/60H, 1.5 kW |

| Weight | 350 kg |

| Dimensions | 1200 × 700 × 1800 mm |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288