Rotary Pouch Sealing Machine NPP-200C

Efficient Rotary Pouch Sealing Machine NPP-200C

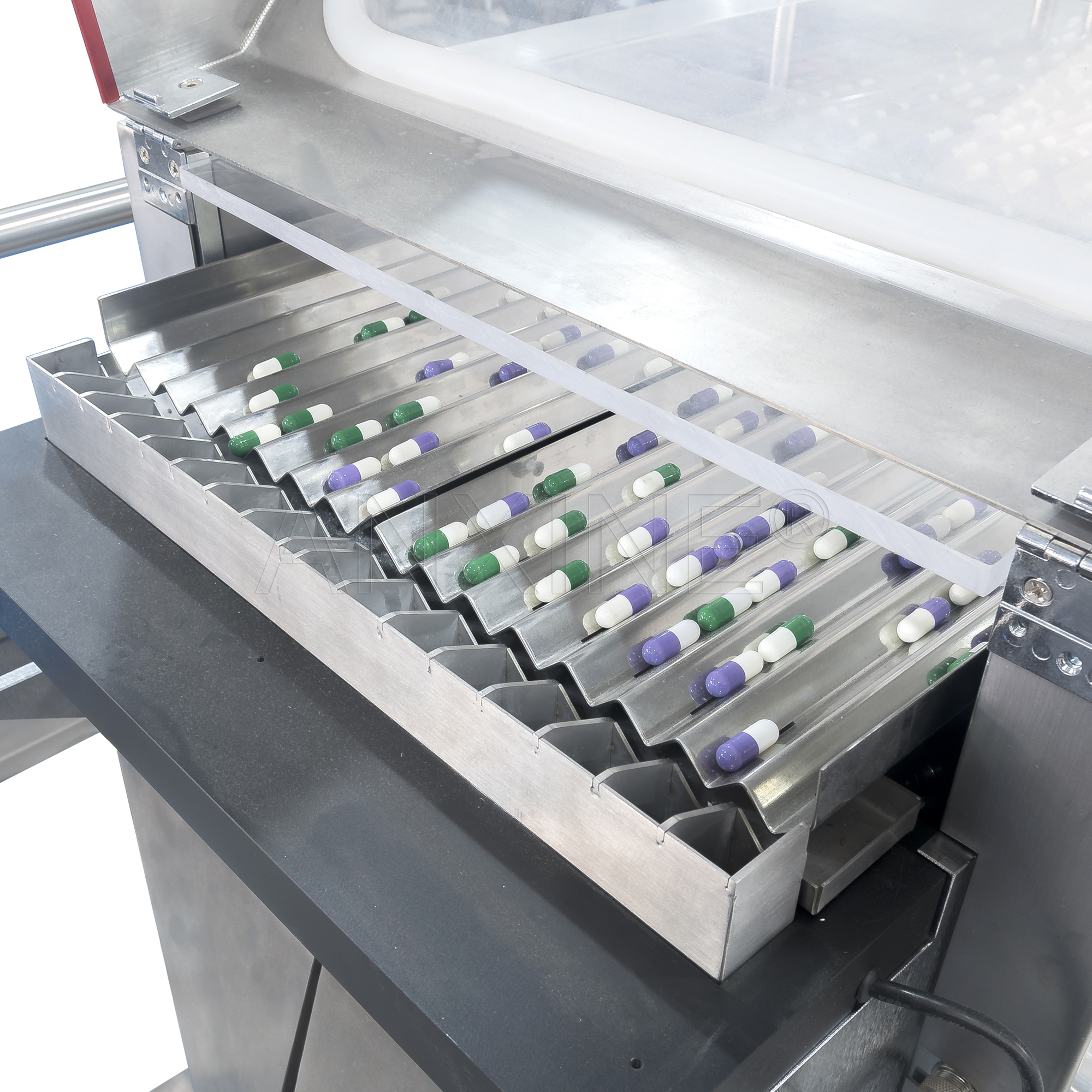

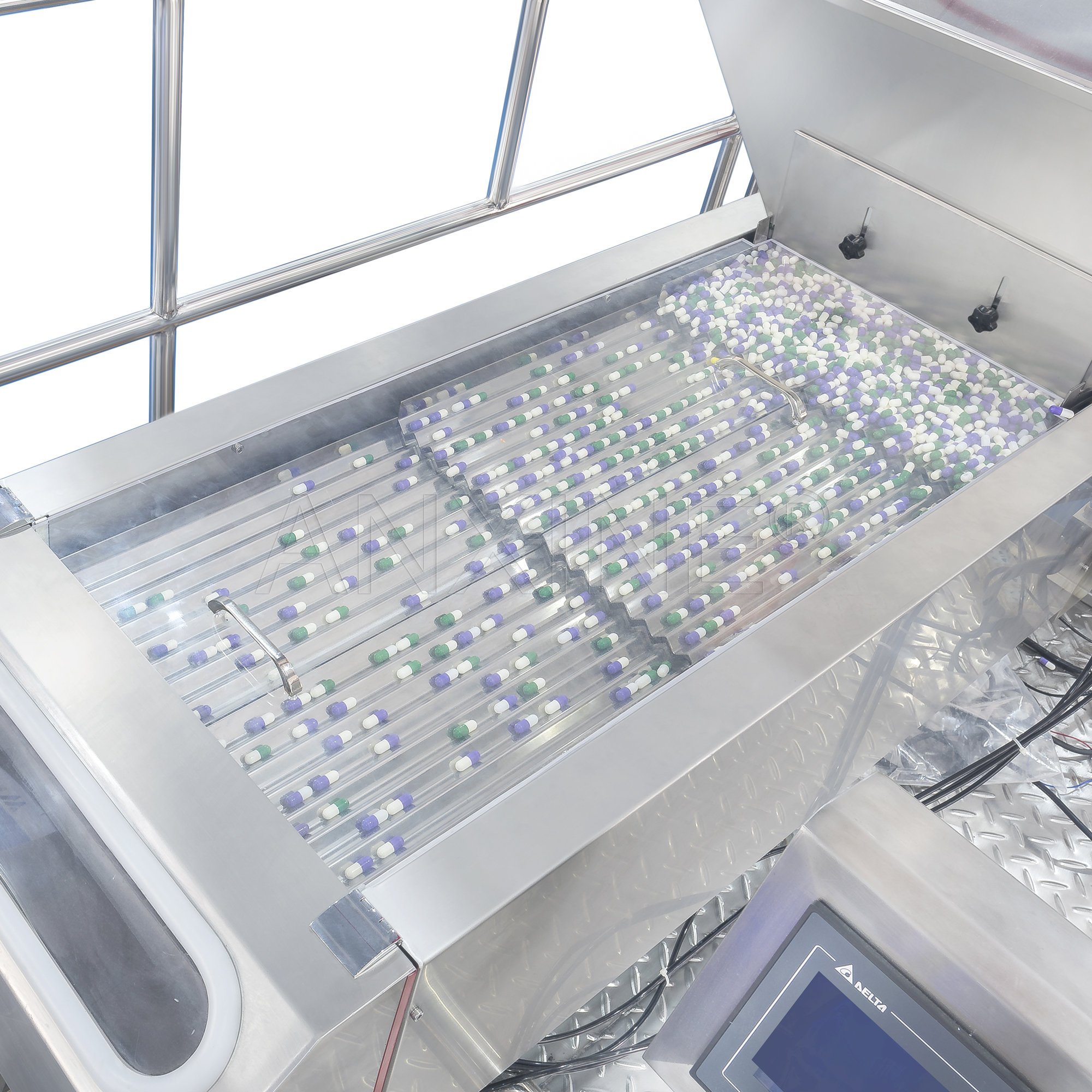

The NPP-200C Rotary Pouch Sealing Machine is an advanced automated packaging system specifically engineered to efficiently handle and precisely package a wide range of solid or granular materials, including capsules, tablets, and powders. This machine integrates cutting-edge technology to automate the entire packaging process—from filling and sealing to output—ensuring not only high productivity but also superior quality and consistency in every packaged unit.

It is designed with precision in mind, capable of processing various materials while maintaining reliability and efficiency, making it an indispensable tool for industries such as pharmaceuticals, food processing, and cosmetics that require dependable pouch packaging solutions. The NPP-200C stands out for its ability to streamline operations, reduce labor costs, and enhance packaging accuracy, thereby contributing significantly to overall operational excellence and product integrity.

Description

The NPP-200C is a versatile packaging solution designed for handling a variety of solid and granular materials, such as capsules, powders, candies, and more. This machine automates the process of inserting materials into preformed pouches and sealing them efficiently.

Highlighted Features

- Fully automated process: The entire process from material feeding to finished product output is automated, reducing manual intervention and improving work efficiency.

- High-precision packaging: The use of advanced sensor technology and intelligent control systems ensures the consistency and accuracy of each packaging, with a very small error range to ensure product quality.

- Versatility: Supports multiple types of preformed bags and different packaging specifications to meet diverse market needs; supports customized bag sizes.

- Easy to use: With an intuitive operating interface, all settings can be completed through the touch screen; at the same time, the machine also comes with detailed help documents to facilitate first-time users.

- High efficiency and stability: The optimized internal component layout and rugged design ensure reliability and durability for long-term continuous work and reduce maintenance costs.

- Strong safety: Multiple built-in safety features, such as overload protection, temperature monitoring, and emergency stop buttons, ensure the safety of operators and the normal operation of the equipment.

- Easy to clean: The modular design allows easy disassembly and cleaning of components to meet strict hygiene standards; at the same time, the smooth and corner-free exterior design also facilitates daily cleaning and reduces the risk of cross-contamination.

- Customized solutions: Customized services are provided according to customer needs, including bag size, packaging speed and other specific functions to meet the needs of specific applications.

- Vacuum suction cup bag opening system: ensures smooth bag opening, reduces bag jamming and improves packaging efficiency.

Specifications

| Model | NPP-200C |

|---|---|

| Bag Type | Supports all heat-sealable preformed side seal bags, fin seal bags, gusseted bags, block bottom bags, zip-lock reclosable bags, and stand-up pouches with or without spouts. |

| Bag Size | Width: 80-200 mm; Length: 100-300 mm |

| Packing Speed | 25-60 bags/min, depending on product and materials |

| Accuracy | >99% |

| Power | 5 KW |

| Air Pressure | 0.6 MPa |

| Applications | Suitable for candy, biscuits, peanuts, cookies, pistachios, crystal candy, brown sugar, daily commodities, cooked food, pickles, puffed food, etc. |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288