Automatic Dropper Bottle Filling and Capping Machine CHS-50

Automatic Dropper Bottle Filling and Capping Machine CHS-50

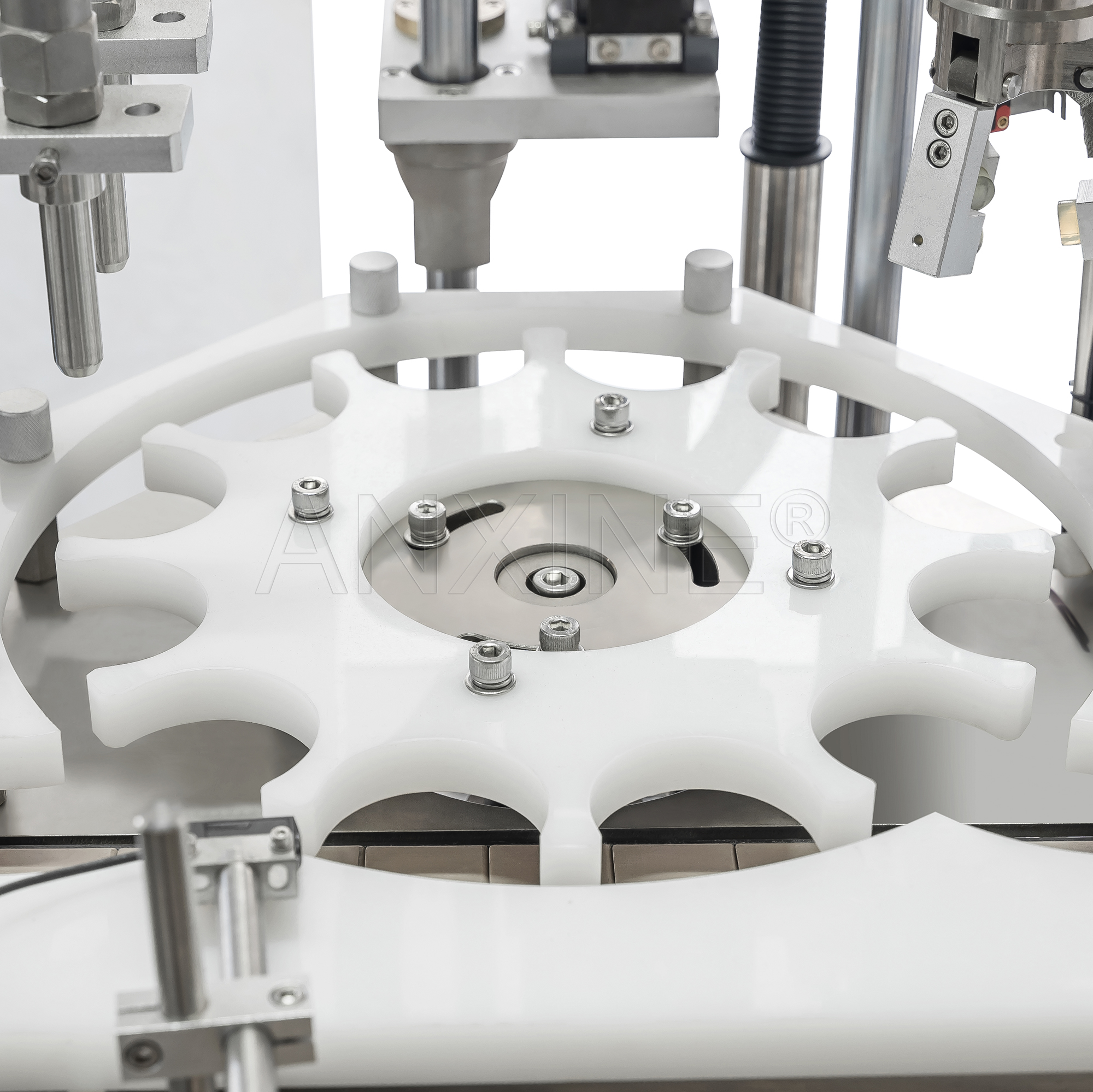

The CHS-50 machine represents a significant advancement in the automation of dropper bottle processing, offering an integrated solution for filling, capping, and screw capping operations. Engineered with cutting-edge PLC control technology, this versatile equipment is designed to ensure precision and efficiency throughout the packaging process. Notably, it incorporates intelligent functionalities such as “no bottle, no filling” and “no cap, no capping,” which prevent wastage by ensuring that actions are only performed when bottles and caps are present.

Additionally, the CHS-50 features an automatic rejection system for products missing their caps, maintaining high standards of quality control. Developed based on extensive industry experience and valuable customer feedback, the CHS-50 is tailored for use with low-viscosity materials across pharmaceutical, food, and chemical sectors. Its design emphasizes user-friendliness, with a straightforward human-machine interface that simplifies operation, while its compact structure optimizes space utilization without compromising on performance. The robust construction and advanced technology behind the CHS-50 guarantee stable and reliable operation, making it an indispensable asset for businesses seeking to enhance productivity and maintain stringent quality standards in their packaging lines.

Description

The CHS-50 machine provides comprehensive automation for filling, capping, and screw capping of dropper bottles. Featuring advanced PLC control technology, it includes functionalities such as “no bottle, no filling” and “no cap, no capping,” as well as automatic rejection of products with missing caps.

Highlighted Features

- Advanced Automation: Provides fully automatic filling, capping, and screw capping processes.

- PLC Control System: Ensures precise control with features like “no bottle, no filling” and “no cap, no capping.”

- High Efficiency: Handles 20-30 bottles per minute, maximizing productivity.

- Filling Accuracy: Offers precise filling with an accuracy of ≤±1%.

- User-Friendly Interface: Equipped with a human-machine interface for easy operation.

- Compact Design: Space-saving structure with stable performance.

- Safety Mechanisms: Includes automatic rejection of products with missing caps to maintain quality control.

- Versatile Applications: Suitable for low viscosity materials in pharmaceuticals, food, and chemicals.

Specifications

| Model | CHS-50 |

|---|---|

| Production Capacity | 20-30 bottles/min |

| Air Pressure | 0.5-0.6 MPa |

| Max Filling Volume | 30ml |

| Power Supply | 220V 50Hz |

| Total Power | 1.5KW |

| Weight | 500kg |

| Dimension | 2,400 × 1,600 × 1,600 mm |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288