Filling Automatic Liquid Filling and Capping Machine CGS-8

Filling Automatic Liquid Filling and Capping Machine CGS-8

The CGS-8 Piston Bottle Filling System is an advanced, customizable solution tailored to meet specific product specifications, spatial limitations, and diverse production environments. Engineered to maximize efficiency and output, this system offers a user-friendly experience through its simple and intuitive touch screen display, making operation accessible even to those less familiar with complex machinery. Utilizing a disc positioning mechanism for both precise filling and accurate cap screwing, the CGS-8 can accommodate a wide range of bottle sizes, enhancing its versatility.

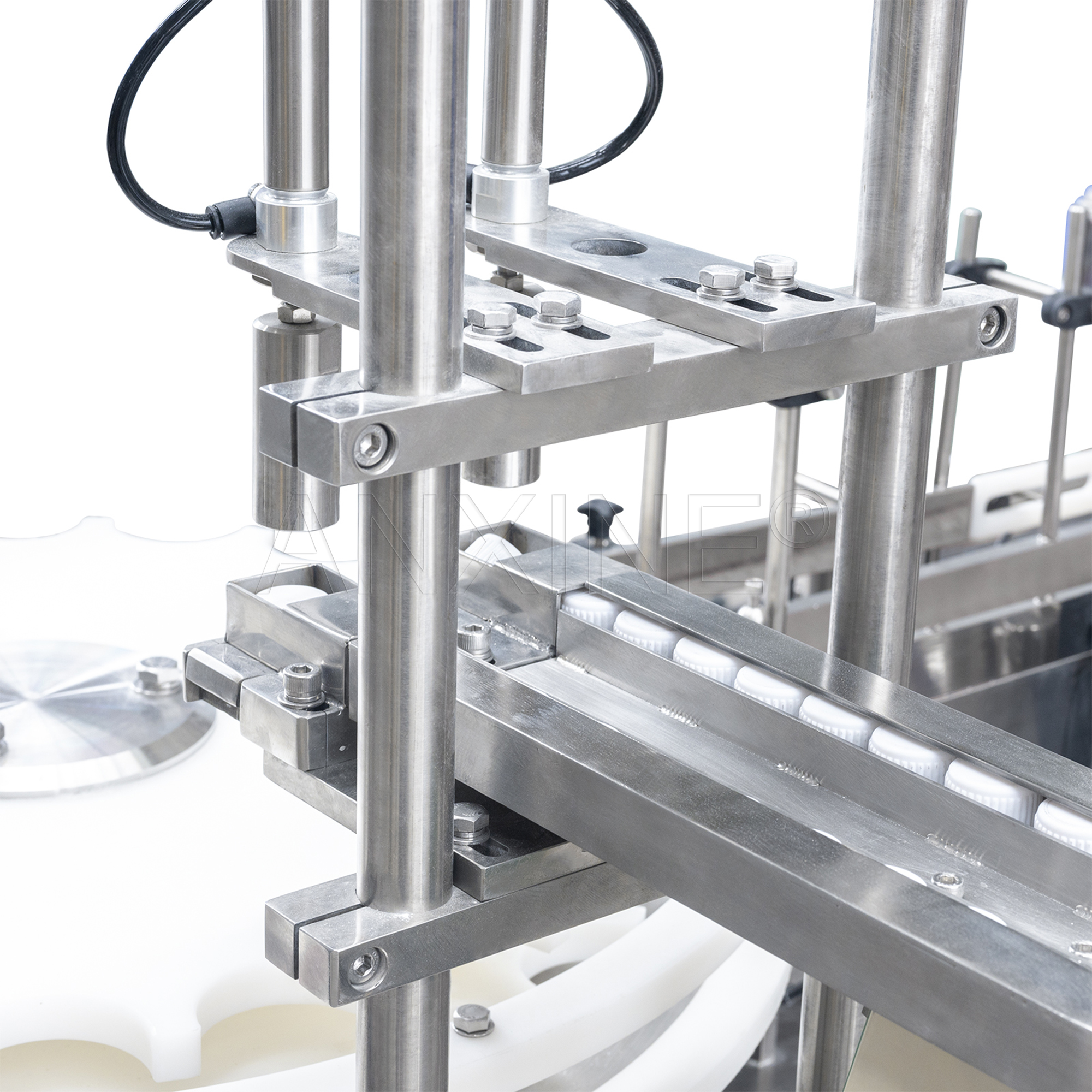

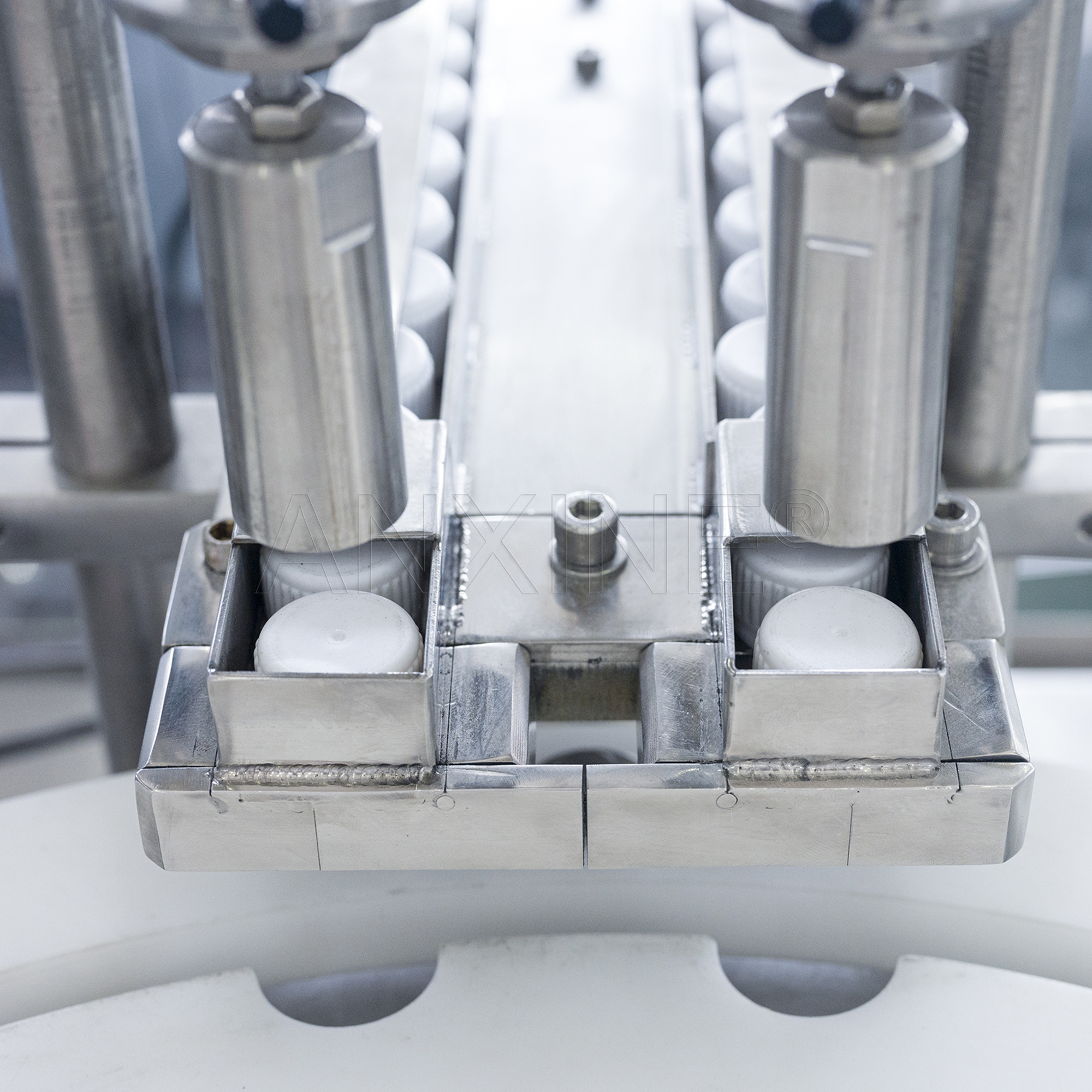

The system features linear 8-head filling technology combined with vibrating disc feeding and cap pressing, which ensures rapid and reliable processing. Its compact yet rational structure facilitates seamless integration with other production equipment, streamlining overall manufacturing processes. The use of a rod-driven piston pump along with high-quality steel transmission components underscores the machine’s durability and operational efficiency. Furthermore, safety and hygiene are prioritized with a protective cover made from PC board and a robust 304 stainless steel frame, ensuring that the CGS-8 not only meets but exceeds industry standards for safe and clean production environments.

Description

The CGS-8 Piston Bottle Filling system is engineered for customization, catering to individual product specifications, space constraints, and production environments. This system is designed to maximize product output, offering a user-friendly experience with a simple and intuitive touch screen display.

Highlighted Features

- Customizable Design: Tailored to meet specific product requirements and space constraints.

- High Efficiency: Capable of filling up to 60-70 bottles per minute.

- User-Friendly Interface: Equipped with an intuitive touch screen display for easy operation.

- Flexible Filling Mechanism: Features linear 8-head filling for diverse bottle sizes.

- Robust Construction: Made with high-quality steel and a protective cover of PC board and 304 stainless steel.

- Versatile Integration: Easily connects with other production line equipment.

- Precision Capping: Includes disc positioning for accurate cap screwing.

- Hygienic and Safe: Designed with a protective cover to ensure safety and maintain cleanliness.

Specifications

| Model | CGS-8 |

|---|---|

| Production Capacity | 60-70 bottles/min |

| Air Pressure | 0.5-0.8 MPa |

| Air Volume | 10-18 m³/h |

| Power Supply | 380V, 50Hz |

| Total Power | 3 kW |

| Weight | Approximately 1050 kg |

| Dimension | 3,000 mm × 1,950 mm × 2,300 mm |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288