Turntable Cartoning Machine DZH-50S

Turntable Cartoning Machine DZH-50S

The DZH-50S cartoning machine is an efficient and precise packaging solution designed for the pharmaceutical, food and other industries to meet the growing demand for automated packaging in these fields. This machine can not only automatically open the carton, load the product and seal the carton, but also is suitable for carton packaging of various sizes and types, greatly improving the flexibility and adaptability of the production line.

The machine is known for its stable and reliable operation performance, precise positioning control, simple operation interface and flexible parameter adjustment functions, making it an indispensable ideal choice for modern production lines. It not only ensures high efficiency and high quality in the packaging process, but also is equipped with a user-friendly touch screen control panel for easy setting, monitoring and maintenance by operators. In addition, the DZH-50S design focuses on safety protection measures, including emergency stop buttons and protective doors, which ensure the safety of operators while ensuring the normal operation of the machine. In short, the DZH-50S is not only an efficient cartoning equipment, but also an intelligent, reliable and high-value-added production partner, committed to providing users with an unparalleled packaging experience.

Description

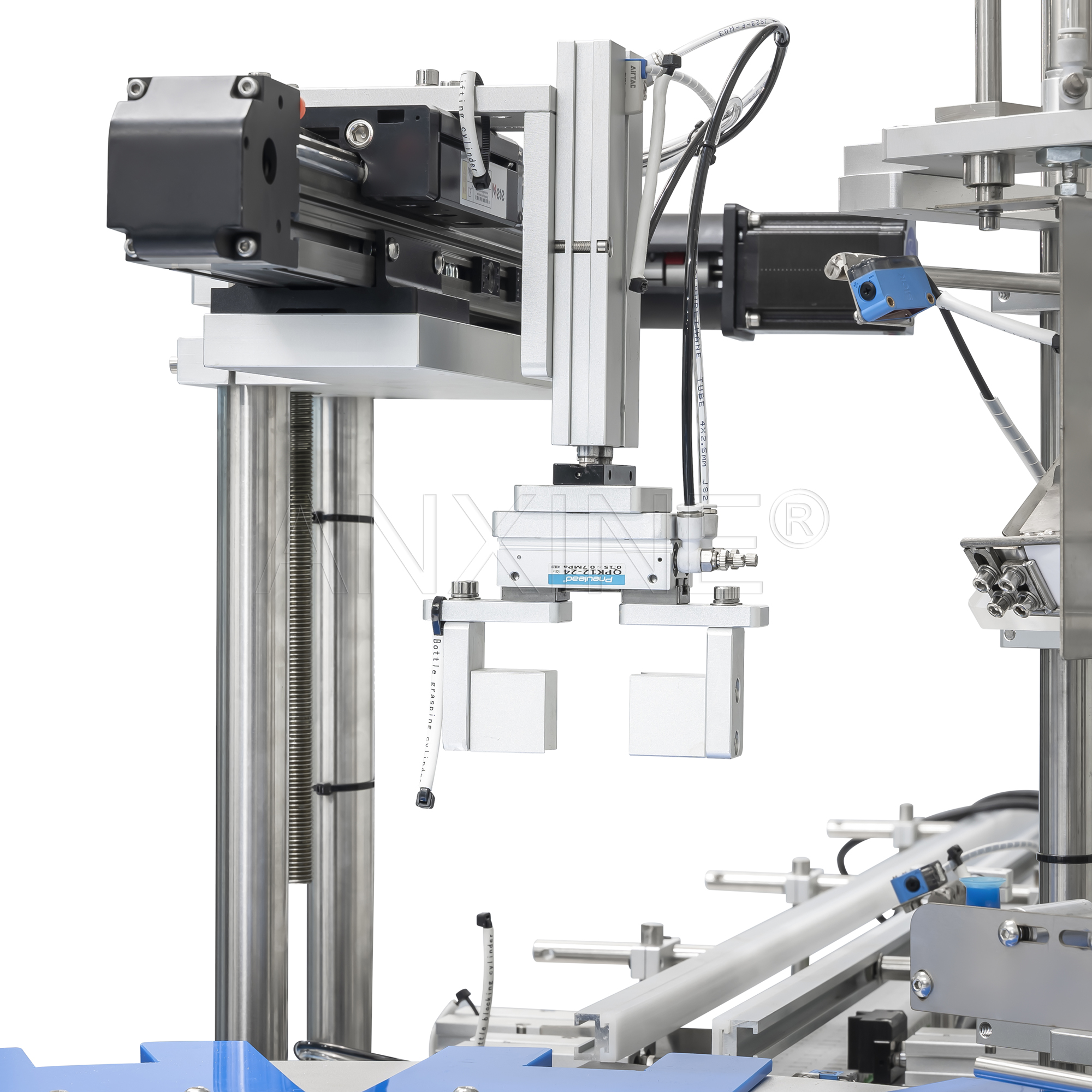

The DZH-50S is an advanced cartoning machine designed to streamline the packaging process with precision and efficiency. It utilizes vacuum suction cups to feed cartons into a star wheel, facilitating a seamless workflow from carton loading to product delivery.

This machine employs vacuum suction cups to guide cartons into the star wheel. The star wheel rotates the cartons to the folding mechanism for bottom sealing. After manual product placement, the star wheel moves the carton to the top sealing mechanism. Finally, the completed product is pushed out for delivery.

Highlighted Features

- Fully automated operation: From the absorption of cartons to the pushing of finished products, the entire process does not require manual intervention and is fully automated.

- Efficient production capacity: The production speed can reach 20-60 cartons/minute, which significantly improves work efficiency.

- Flexible to adapt to different specifications: supports carton sizes from a minimum of 60×20×20mm to a maximum of 200×80×80mm, suitable for a variety of product packaging needs.

- Safety protection measures: Equipped with an emergency stop button to ensure the safety of the operator; it is also equipped with a protective door that is not allowed to be opened during the operation of the machine.

- User-friendly touch screen interface: Provides an intuitive and easy-to-use operation panel to facilitate user parameter setting and troubleshooting.

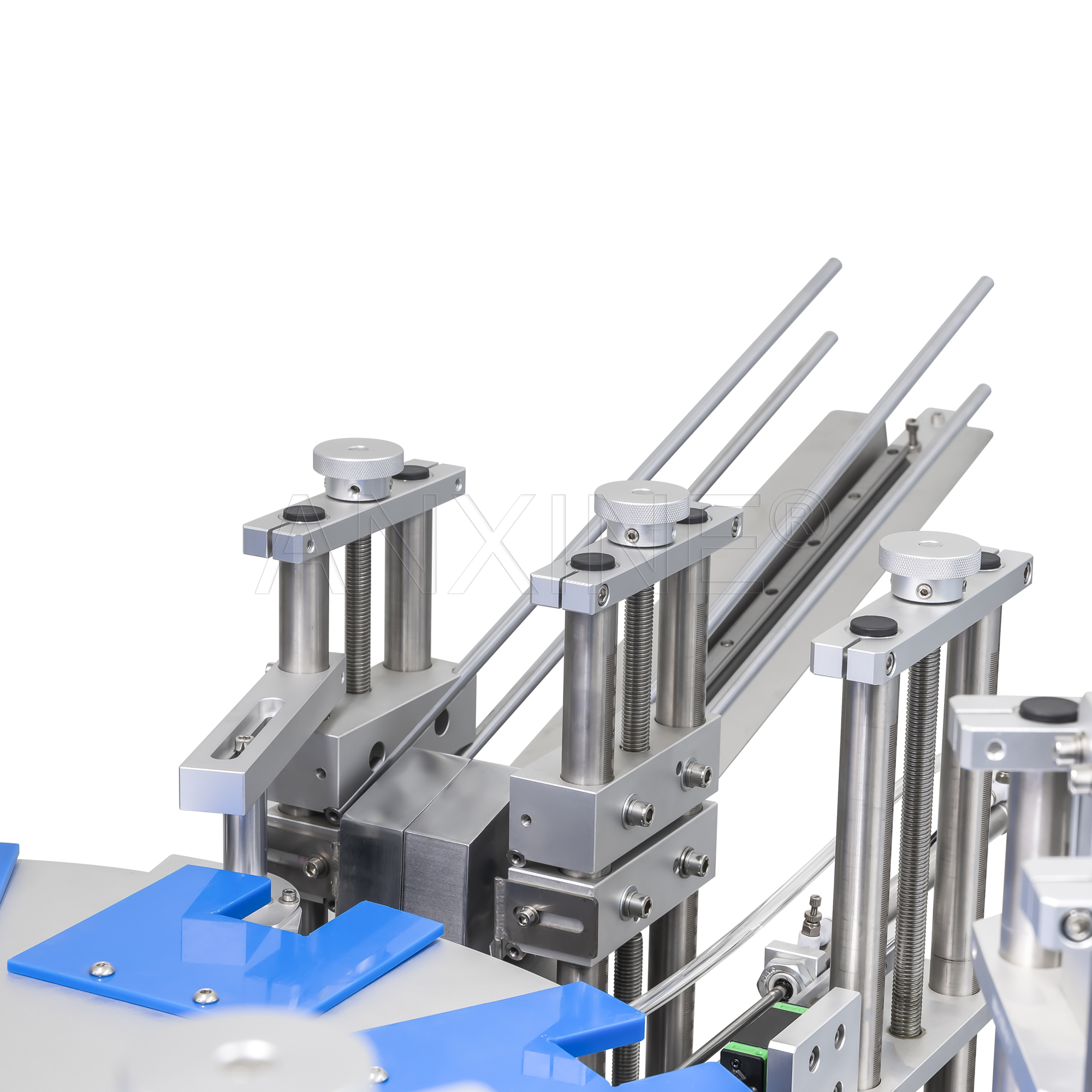

- Fine mechanical adjustment: Each key part such as the carton feeding mechanism, ear folding mechanism, etc. can be fine-tuned according to specific conditions to ensure the best working condition.

Specifications

| Model | DZH-50S |

|---|---|

| Carton Dimensions | Minimum: 60x20x20 mm Maximum: 200x80x80 mm |

| Production Speed | 20-60 cartons/min |

| Power Supply | 220V single phase; 50/60Hz |

| Motor Horsepower | 1/4HP 15:1 |

| Air Pressure Consumption | 150L/min |

| Dimensions | 1,750 x 1,200 x 1,500 mm |

| Weight | 950 kg |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288