Semi-Automatic Liquid Capsule Filling Machine JTJ-L

Semi-Automatic Liquid Capsule Filling Machine JTJ-L With Automatic Turntable

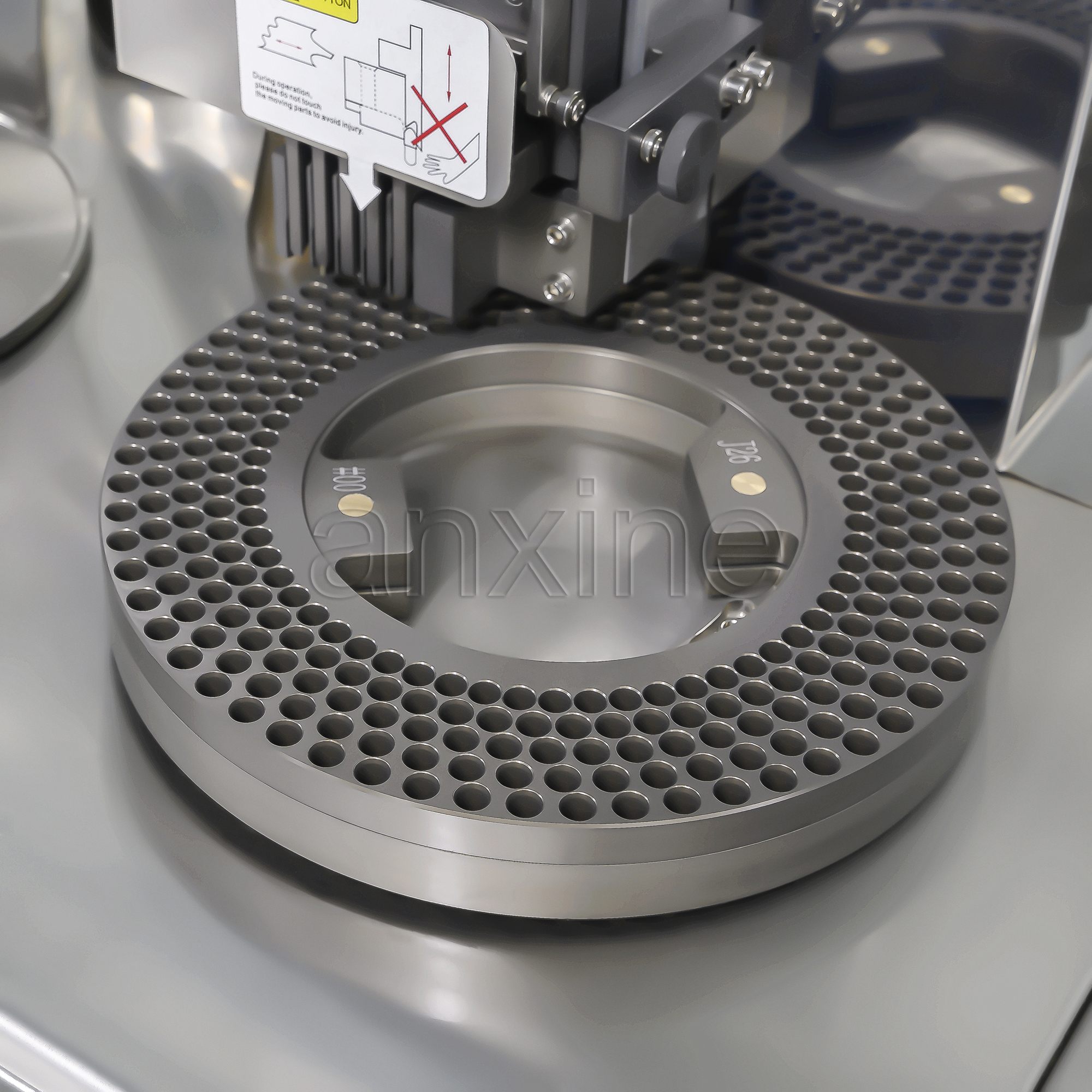

The JTJ-L is a semi-automatic liquid capsule filling machine designed for the precise filling of liquid materials into capsules, featuring variable frequency speed regulation that enables outputs of up to 10,800 capsules per hour, depending on the operator’s proficiency and the capsule model, with compatibility covering sizes 00#, 0#, 1#, 2#, 3#, and 4#.

Key components include a feeding and turning separation mechanism for smooth handling, a precise filling mechanism, a reliable locking mechanism, a frequency conversion speed regulation system for adjustable operation speeds, pneumatic control for precise movement, an electrical control system for intuitive operation, protection devices for safety, and vacuum and air pump accessories to ensure efficient capsule processing.

Description

The JTJ-L is a semi-automatic liquid capsule filling machine featuring variable frequency speed regulation. It achieves outputs of up to 10,800 capsules per hour, depending on the operator’s proficiency and the capsule model. It is compatible with capsule sizes 00#, 0#, 1#, 2#, 3#, and 4#.

Highlighted Features

- Enhanced Accuracy and Efficiency: The machine improves upon the inefficiencies and inaccuracies associated with manual liquid filling by employing mechanical liquid filling methods.

- Precision Suction and Dispensing: Utilizes a suction pump alongside a control valve system to precisely extract and dispense liquid, ensuring accurate dosing.

- Continuous Operation: Incorporates a driving motor and material turntable design to facilitate uninterrupted and efficient addition of liquid into capsules.

- High-efficiency production capacity: With variable frequency speed regulation function, the maximum output can reach 10,800 capsules per hour.

- Wide applicability: Compatible with various types of capsules such as 00#, 0#, 1#, 2#, 3#, and 4#.

- Easy maintenance: Provide detailed cleaning and maintenance guides to ensure long-term stable operation of the machine.

- Safe and reliable: Adopt 380V50Hz three-phase four-wire power supply, and emphasize the importance of grounding protection to ensure user safety.

- Humanized design: From capsule pouring to finished product collection, each step has been carefully designed to provide a convenient operating experience.

- Modular structure: Key components such as capsule delivery, turning and separation mechanism, filling mechanism, etc. are designed as modular, which is easy to repair and upgrade.

Specifications

| Model | JTJ-L |

|---|---|

| Output | 1-10,800 capsules per hour (dependent on operator skill and capsule type) |

| Capsule Size | 00#, 0#, 1#, 2#, 3#, 4# |

| Filler Drug Type | Liquid material |

| Total Power | 3.2 kW |

| Compressed Air | 0.03 m³/min, 0.7 MPa |

| Vacuum Pump | 40 m³/h |

| Overall Dimensions | Length: 1,130mm Width: 700mm Height: 1,600mm Weight: 400kg |

| Package Size | Length: 1,650mm Width: 720mm Height: 1,800mm Weight: 500kg |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288