Automatic Capsule Filling Machine NJP-4000D

Automatic Capsule Filling Machine NJP-4000D

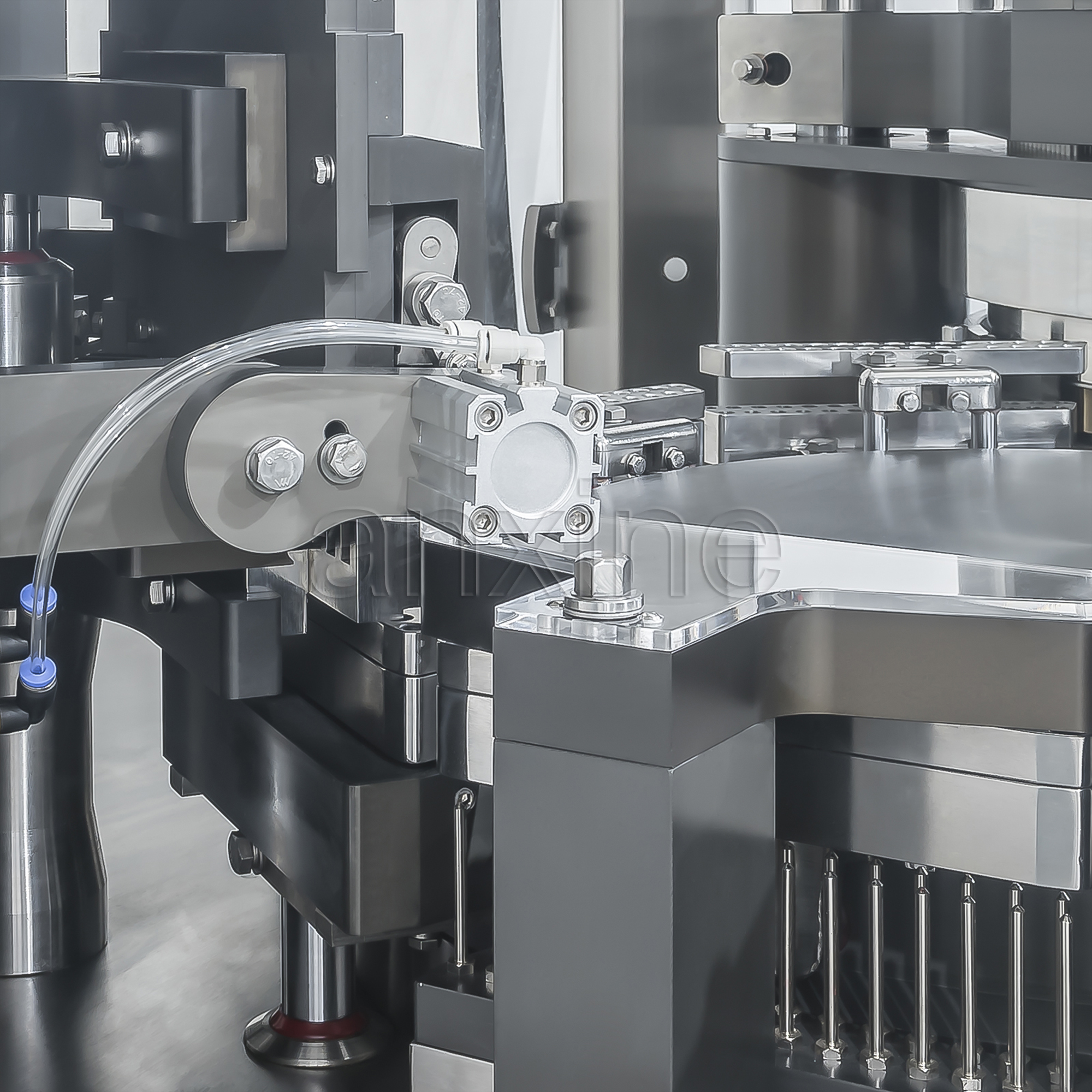

The NJP-4000D fully automatic capsule filling machine launched by Anxine Machinery is designed for efficient pharmaceutical production. It can accurately fill capsules of various specifications (00# to 5#) at a speed of 4,000 capsules per minute, ensuring the perfect combination of high speed and high precision.

The machine adopts a multi-station turntable structure and an advanced automatic control system. It realizes automatic separation, filling, compaction and discharge of capsules through precise mechanical transmission and electronic control systems, ensuring that the whole process is efficient and error-free. Equipped with a user-friendly touch screen interface, it simplifies operation and supports real-time monitoring.

All operations comply with GMP standards to ensure the compliance and safety of drug production. In addition, the NJP-4000D has a flexible parts replacement system that can quickly adapt to different types of capsule production needs and minimize downtime. It is an ideal choice for modern pharmaceutical companies to improve production efficiency.

Description

The NJP-4000D is a high-accuracy automatic capsule filling machine designed for maximum productivity, capable of processing up to 4,000 capsules per minute. It offers low-maintenance operation, minimal downtime, and dependable production.

Highlighted Features

- Ease of Use: Simple operation and maintenance at low cost.

- Adjustability: Flexible settings improve filling levels and production efficiency.

- Enclosed Design: Tightly sealed parts prevent dust and contamination.

- Automated Efficiency: Automatic filling saves time and energy.

- Safety Sensors: Alerts for potential operational issues.

- Filling Level Detection: Automatic sensors assist in monitoring hopper levels.

- Capsule Integrity: Designed to minimize capsule damage.

- Precision Filling: Ensures accurate filling levels across capsules.

- Integration Capability: Easily integrates with other machines for full encapsulation processes.

- Compliance: Meets CE and cGMP quality standards for high assurance in quality.

- High-Precision Dosing: Utilizes 5-stage tamping technology for enhanced powder dosing accuracy. Pellet filling is also supported.

- Capsule Process: Capsules are fed from the bunker into an orienting device, then into rotor cells where they are separated. The bottom part is filled and non-separated capsules are rejected before joining with the top part for completion.

Specifications

| Model | NJP-4000D |

|---|---|

| Maximum Output | 240,000 capsules per hour |

| Capsule size range | 00#-5# and safety capsule |

| Electrical Supply | 380/220v,50/60Hz |

| Total Power | 12 kW |

| Vacuum | -0.02 ~ 0.06 MPa |

| Noise | <70dB |

| Ambient Temperature | 21 ± 3℃ |

| Relative Humidity | 40-55% |

| Overall Dimensions | Length: 1,950mm Width: 1,260mm Height: 2,380mm Weight: 2,800kg |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288