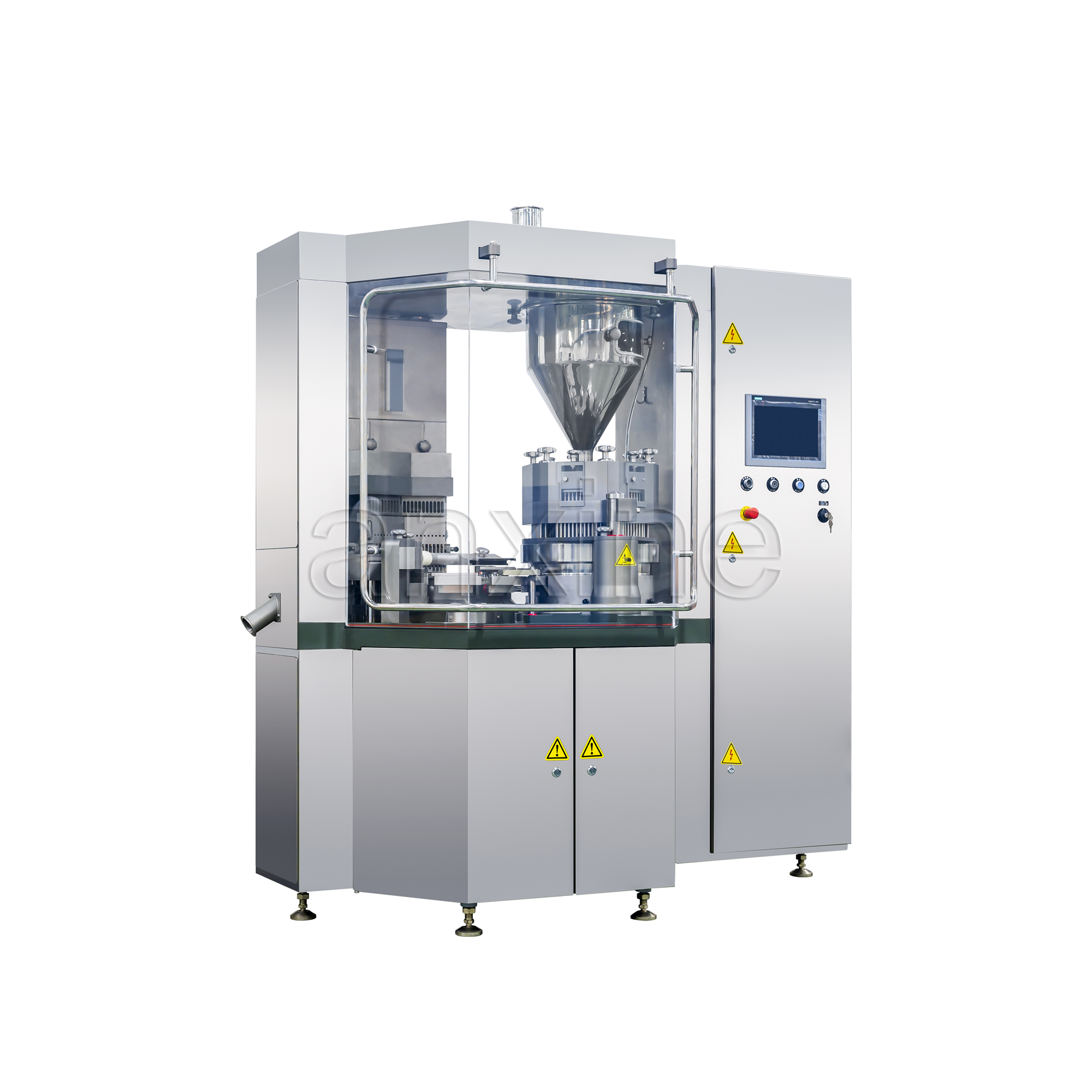

Automatic Capsule Filling Machine NJP-3000 Ultra

Automatic Capsule Filling Machine NJP-3000 Ultra

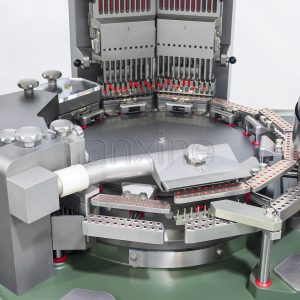

NJP-3000 Ultra is an advanced high-speed, efficient, high-precision fully automatic capsule filling solution designed for the pharmaceutical industry. It is suitable for filling hard shell capsules of various standard sizes, including those most difficult to handle product types. The equipment adopts continuous cam control technology, and key parts use FCD700 high wear-resistant materials and Japan Sankyo indexing gearboxes to ensure low noise and smooth transmission, while having good temperature control (maximum temperature rise does not exceed 60°C).

NJP-3000 Ultra has a small footprint, is easy to connect various pipelines, is simple and fast to maintain, and is easy to replace molds. It has a modular structure and supports flexible configuration of powder and micro-pellet filling. It is operated by a touch screen, with a user-friendly interface that simplifies the operation process.

In addition, it complies with the requirements of the EU Machinery Directive 2006/42/EC and other relevant regulations, ensuring the safety and health of users. This machine also optimizes the design to reduce energy consumption and improve work efficiency, making it an ideal choice for modern pharmaceutical production.

Description

The NJP-3000 Ultra is a state-of-the-art full-automatic capsule filling machine, perfect for filling a variety of products such as powder, pellets, and mixtures. It features high filling accuracy, an adjustable dosing disc, and a powder-saving design, making it an ideal choice for the pharmaceutical, healthcare, and food industries.

Highlighted Features

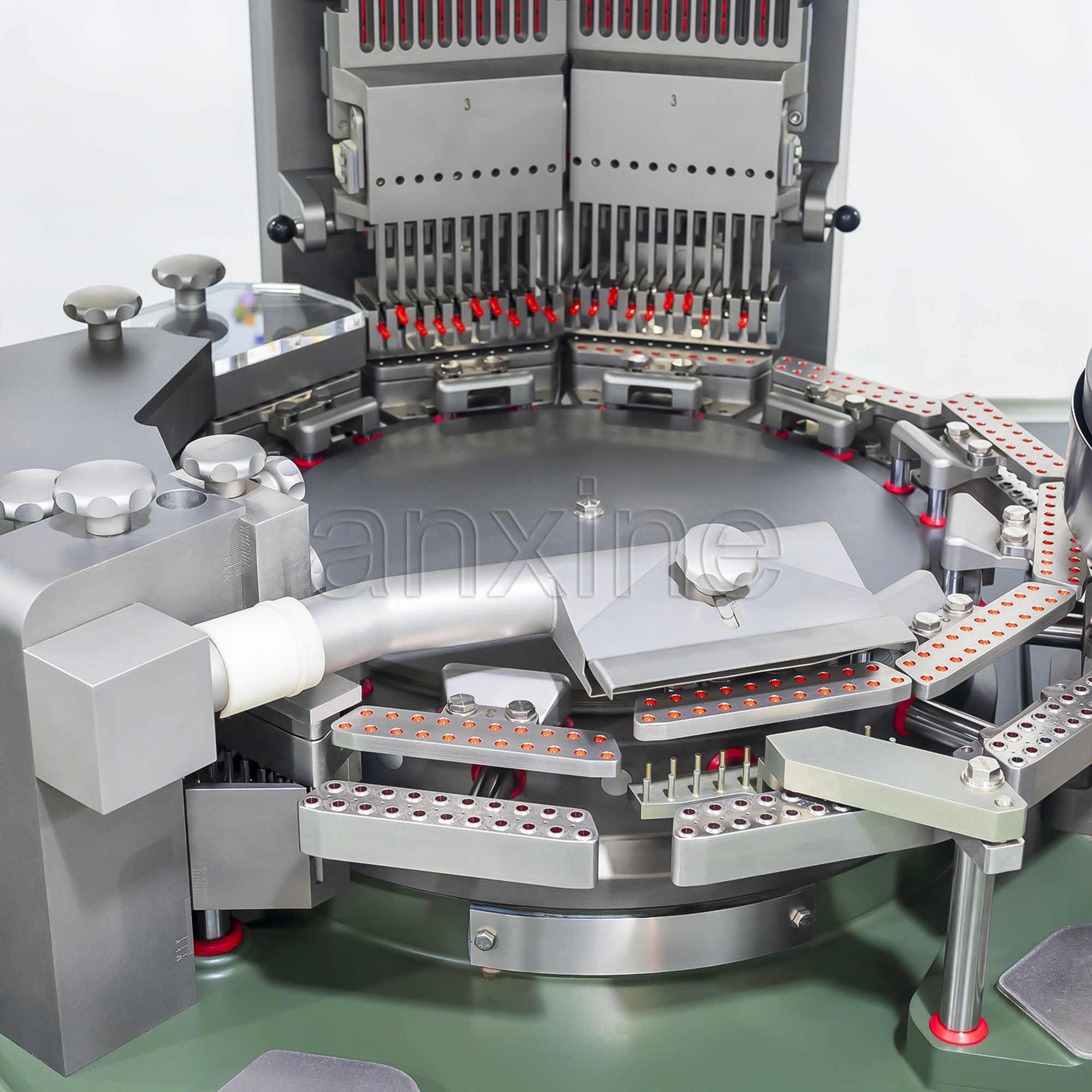

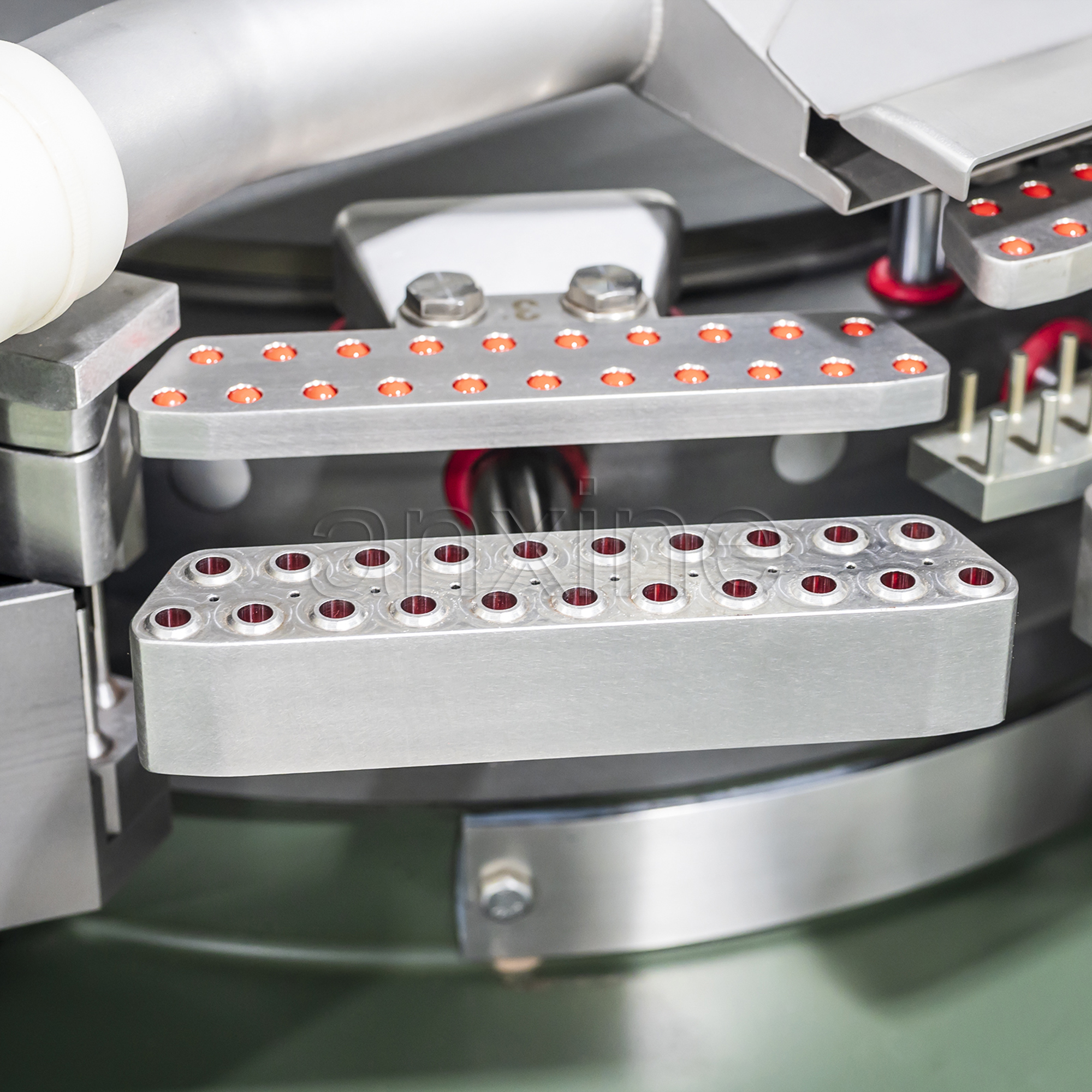

- High Precision and Efficiency: With a maximum capacity of 176,400 capsules per hour, the NJP-3000 Ultra ensures efficient production. It supports capsule sizes from 00# to 5# with 21 segment bores.

- Advanced Design: Incorporates an international advanced design concept with a high precision metering disc filling rod. The design aligns with CGMP and FDA specifications, highlighting its commitment to quality and safety standards.

- Reliable and Durable Components: The NJP-3000 Ultra uses top-quality components like the German Nord motor and Japanese cam splitter for stable performance, long service life, and low noise operation.

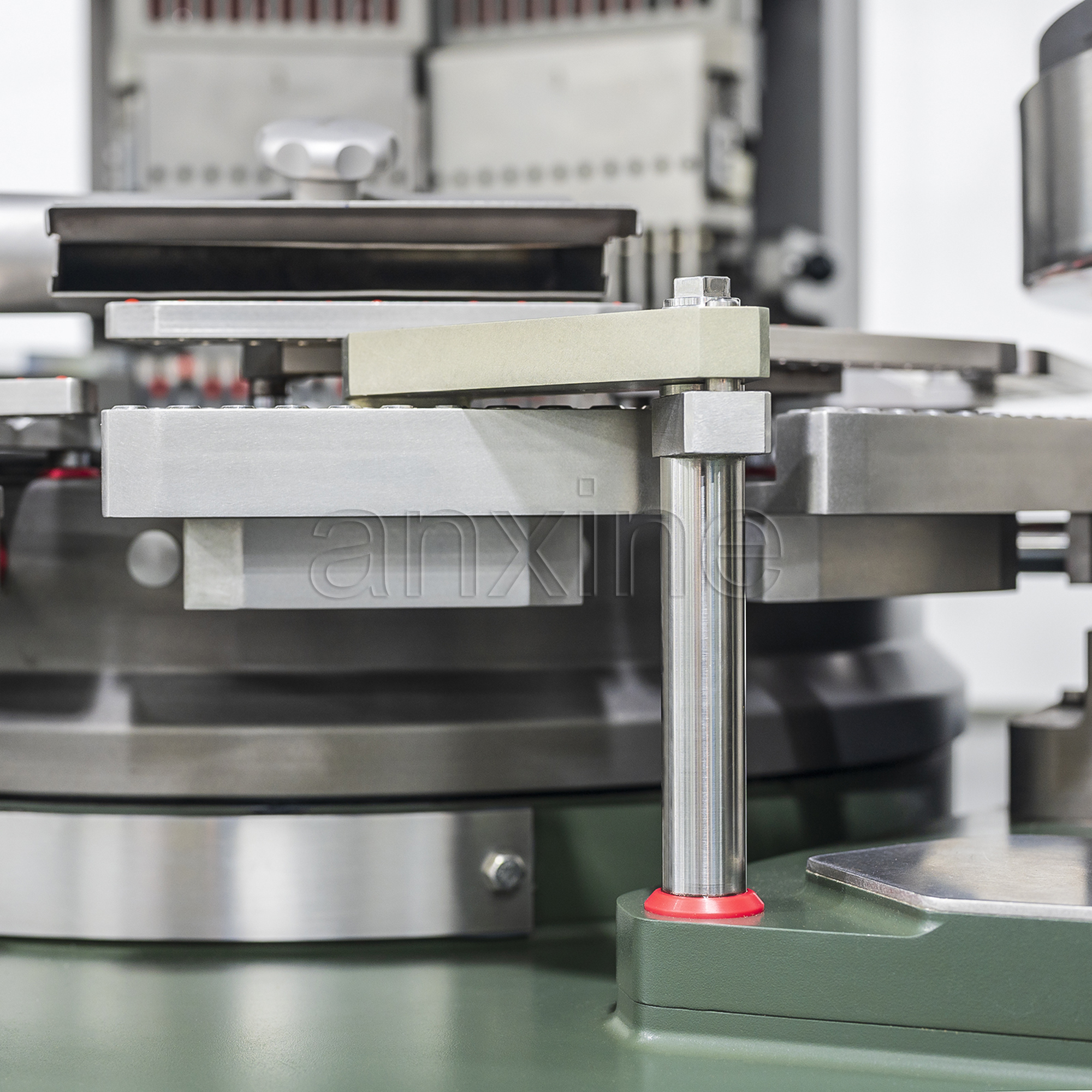

- Energy-Efficient: Features low-energy consumption motors and a monolithic platen design to prevent powder leakage, ensuring a clean work environment.

- Innovative System Configuration: Equipped with the German SIEMENS system, including inverter drive and PLC program control for safe and reliable operations.

- User-Friendly Design: Offers smooth operation with quick and simple mold replacement. The entire process, from capsule sorting and separating to filling and cleaning, is automated.

- Protective and Robust: Key parts are covered with protective sleeves and double sealing rings to enhance durability and prevent dust ingress.

- Material Quality: Equipped with high-strength aluminum alloy work surfaces for superior performance.

- Easy Integration: Comes with an empty capsule feeding machine that seamlessly integrates with the NJP Ultra series for efficient operation.

Specifications

| Model | NJP-3000 Ultra |

|---|---|

| Maximum Output | 176,400 capsules per hour |

| Suit for capsule size | 00#-5# |

| No.of segment bores | 21 |

| Electrical Supply | 380V/50Hz, three-phase five-wire |

| Total Power | 10kW |

| Overall Dimensions | Length: 2,020mm Width: 1,276mm Height: 2,343mm |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288