Automatic Bottle Unscrambler CBL-Z

Automatic Bottle Unscrambler CBL-Z

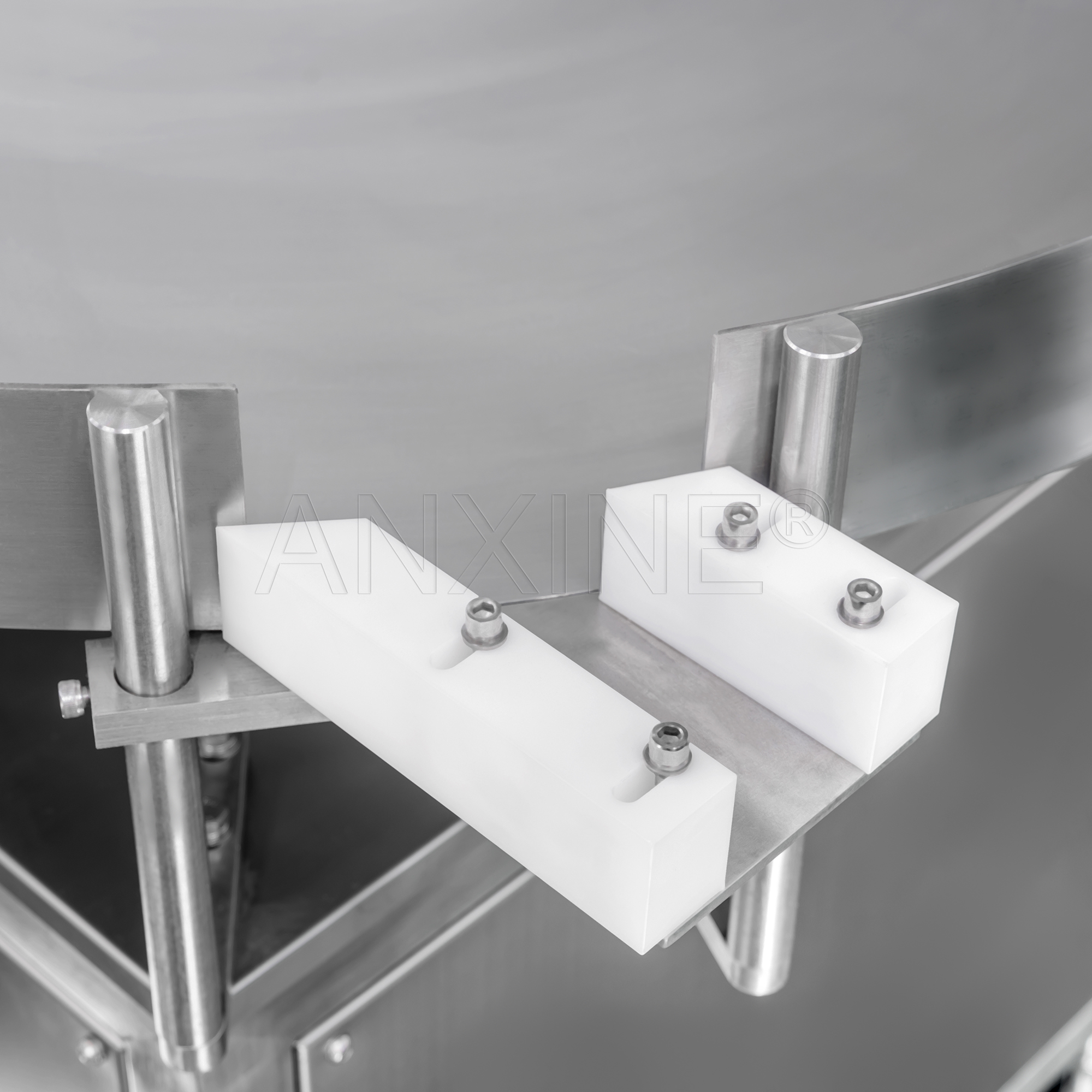

The Automatic Bottle Unscrambler CBL-Z is an efficient automatic plastic bottle sorting machine designed for the pharmaceutical, cosmetic and food and beverage industries. This equipment can handle bottles of a variety of materials (such as glass bottles, plastic bottles) and shapes (round bottles, square bottles). The disordered bottles are arranged neatly through the blocking baffle on the rotating workbench, and are accurately transported to the next A processing procedure that significantly improves the automation level and efficiency of the production line.

The design of CBL-Z focuses on user-friendliness and ease of operation. All electrical components need to be well grounded to ensure safe operation. At the same time, it has a conveying capacity of 30 to 45 bottles per minute, making it suitable for various industries that need to arrange bottles quickly and accurately. application scenarios. In order to ensure the best performance of the equipment, it is recommended to let the machine idle for 30 minutes for a preheating check before formal production.

In addition, CBL-Z equipment has a compact structure and is easy to install and debug, ensuring good connection with other equipment in the production line. Daily cleaning and regular inspection of wearing parts ensures long-term stable operation of the equipment.

Description

The Automatic Bottle Unscrambler CBL-Z is an efficient automatic plastic bottle sorting machine designed for the pharmaceutical, cosmetic and food industries. It can handle glass bottles, plastic bottles, and round and square bottles, significantly improving the efficiency and automation level of the production line by neatly arranging and transporting disordered bottles to the next process.

Highlighted Features

- Wide applicability: Suitable for a variety of industries, including but not limited to pharmaceutical, cosmetic and food and beverage industries, supporting bottles of different materials (such as glass, plastic) and shapes (round bottles, square bottles).

- Efficient sorting capacity: It has a conveying capacity of 30 to 45 bottles per minute, which significantly improves the efficiency of the production line.

- Safe and reliable operation: All electrical components need to be well grounded to ensure the safety of operation; at the same time, the design of the equipment fully takes into account the user-friendly interface and simple operation process.

- Easy maintenance: Daily cleaning and regular inspections are key to maintaining equipment performance. All parts should be cleaned by wiping instead of spraying, and wearing parts should be routinely inspected every month to ensure long-term stable operation of the equipment.

Specifications

| Model | CBL-Z |

|---|---|

| Conveying Capacity | 30-45 bottles/min |

| Power Supply | 220V 50HZ |

| Total Power | 0.5KW |

| Rotary Plate Dimension | Φ1000 ×1000 mm |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288