Automatic Desiccant Sachet Filling Machine CSR-I

Automatic Desiccant Sachet Filling Machine CSR-I

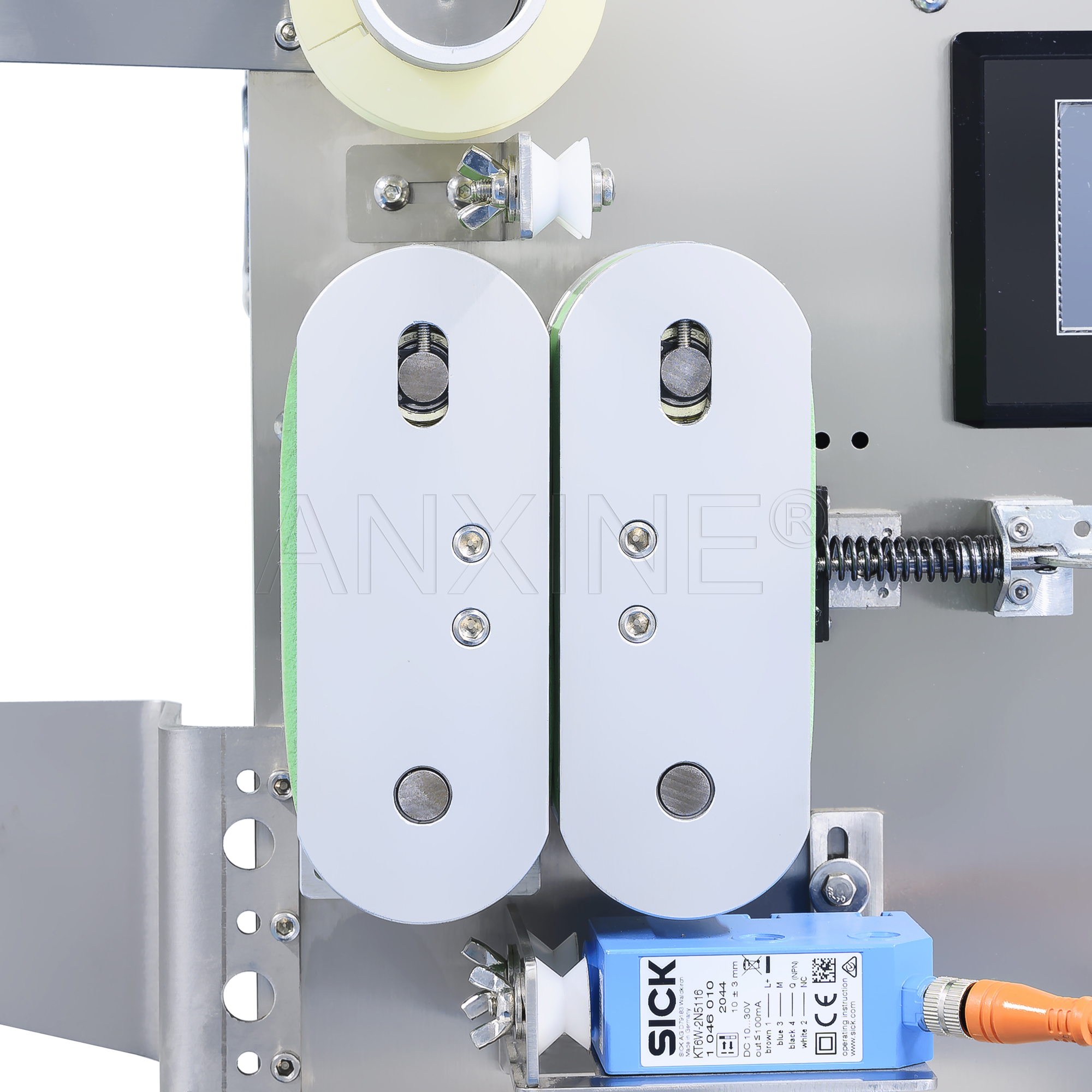

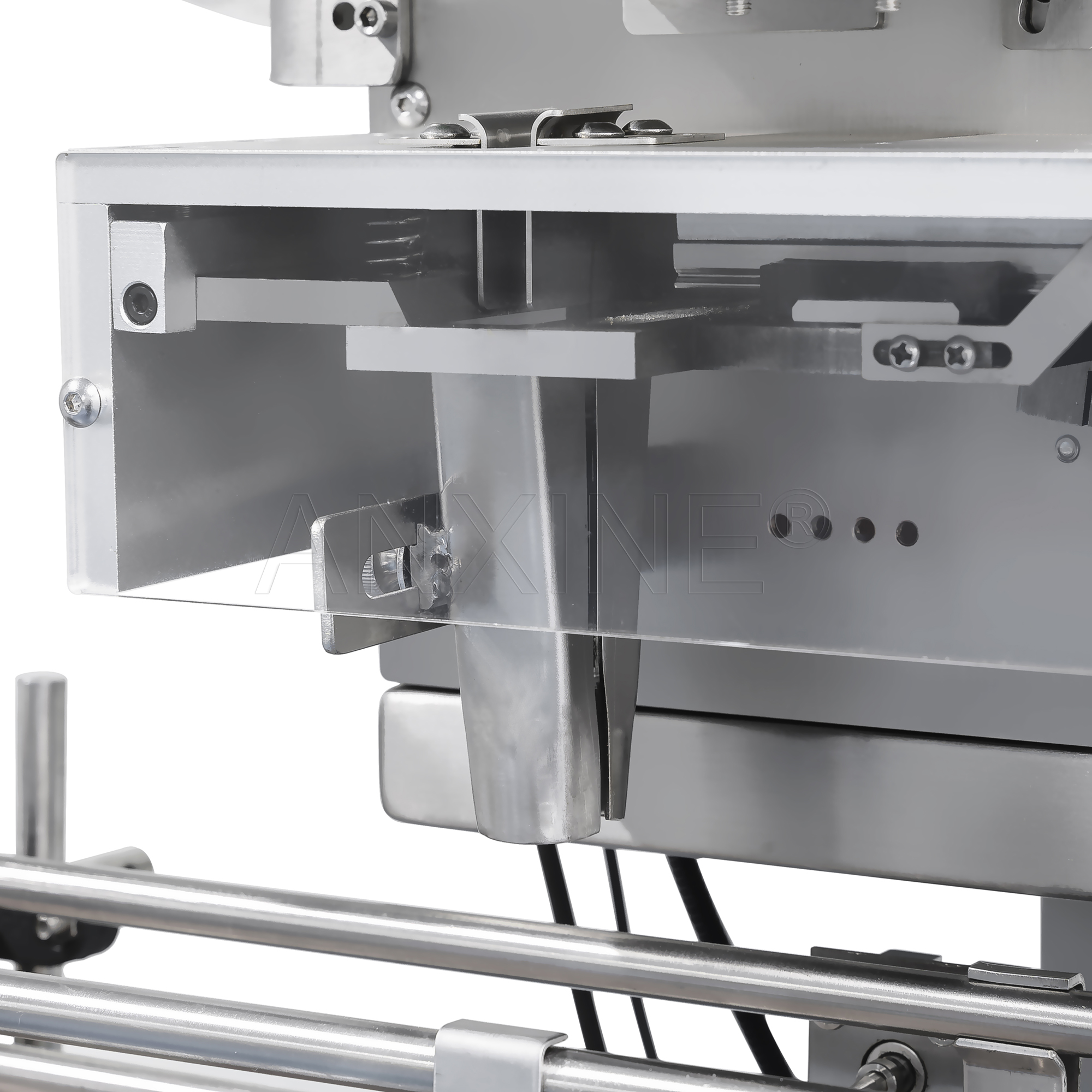

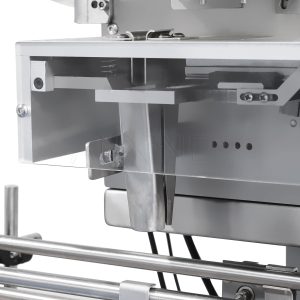

The working principle of the CSR-I automatic desiccant bag filling machine is as follows: when the bottle advances on the conveyor belt and is detected by the sensor, the position fixing cylinder is activated to block the bottle and position its bottle mouth below the material discharge port. Subsequently, the desiccant strips processed by the pressing roller are broken into appropriate lengths by the cotton pulling wheel and pushed into the duct inside the bottle mouth by the cylinder. Then, the face plate stepper motor rotates 90 degrees to move the bottle filled with desiccant to the conveyor belt, while new empty bottles are replenished to the filling position. This series of actions is carried out continuously, ensuring a smooth and efficient production process. In addition, in order to facilitate the operator to monitor and control the entire process, the machine is equipped with a 7-inch color LCD touch screen controller, which provides an intuitive operation interface and detailed parameter setting options to help users easily achieve automated production and quality control.

Description

The CSR-I is a fully automatic desiccant sachet filling machine manufactured by CapsulCN. This machine is designed for precision and efficiency, offering advantages such as accurate cutting, easy maintenance, and low operational costs. It is constructed from 304 stainless steel and complies with GMP standards, ensuring high-quality performance.

Highlighted Features

- Precise filling: The ribbon sensor and high-precision cutting device ensure the consistency and accuracy of each filling amount.

- High efficiency and energy saving: It can process 80 to 160 bottles per minute while maintaining low energy consumption and reducing operating costs.

- Intelligent control system: The 7-inch color LCD touch screen controller supports direct data input, real-time display of production information (such as cumulative output, speed, etc.), and can provide alarm prompts in the event of a fault.

- Compact design: Small size, space-saving, suitable for production workshops of different sizes.

- Safe and reliable: All electrical components must be well grounded to ensure the safety of operators; the equipment has built-in multiple protection mechanisms, such as no bottle does not work, automatic shutdown of sensor failure, etc., to ensure stable operation.

- Ease of use and maintainability: Simple structure, easy to adjust and maintain; regular addition of lubricating oil and checking the status of key components can extend the service life; using absolute alcohol to clean the surface that contacts the product helps maintain hygiene standards.

- GMP compliance: Made of 304 stainless steel, it meets the requirements of pharmaceutical production quality management specifications and is suitable for industries with strict requirements on hygiene conditions.

Specifications

| Model | CSR-I |

|---|---|

| Filling Speed | 80-160 bottles per minute |

| Compressed Air | 0.3-0.4 Mpa |

| Input Voltage | 220V/50Hz or 110V/60Hz |

| Power | 500W |

| Dimensions | 1,430 x 989 x 524 mm (Height Adjustable) |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288