Semi-Automatic Small Blister Packing Machine ABM-I

Semi-Automatic Blister Packing Machine for Small Industries ABM-I

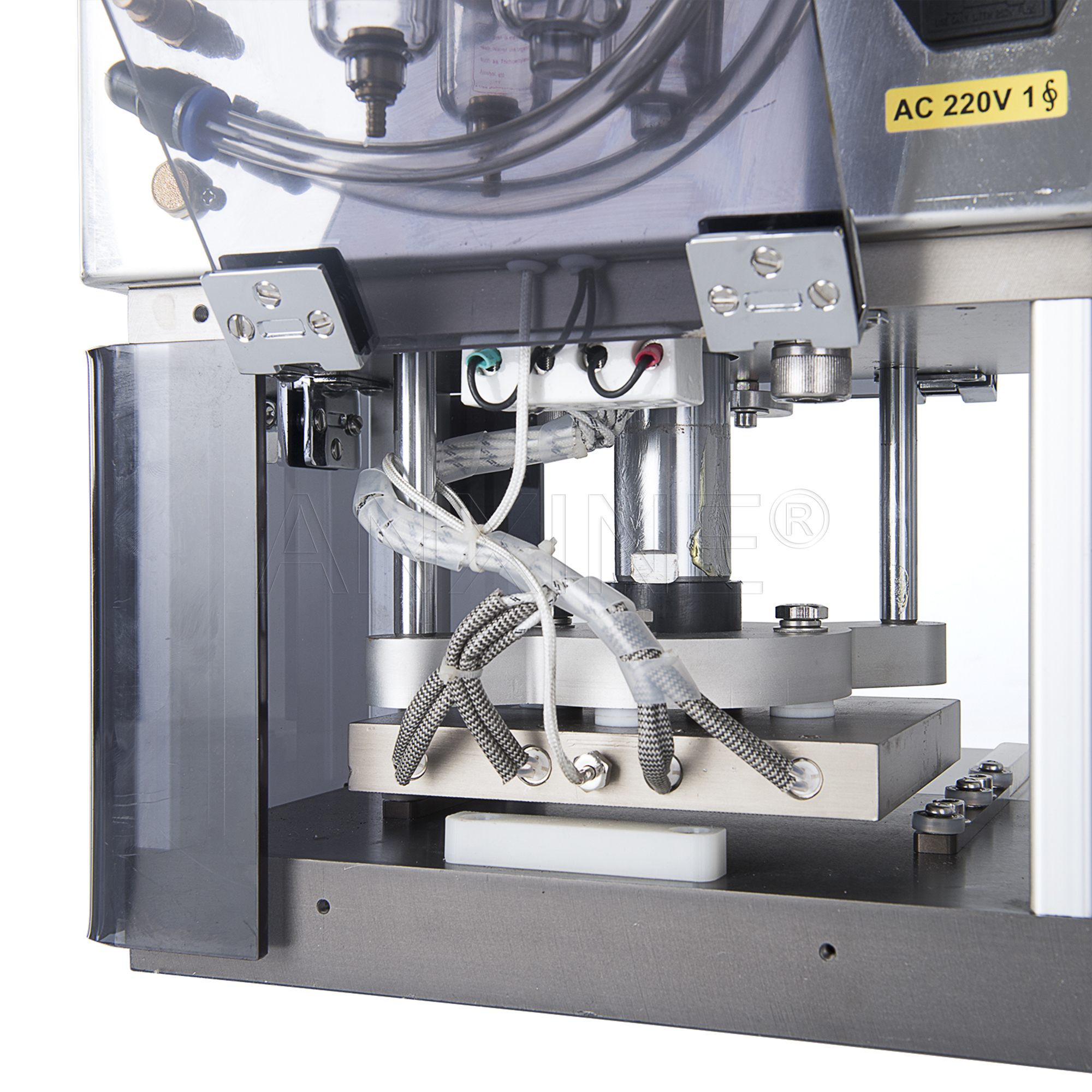

The ABM-I blister packaging machine is designed to improve product quality and production efficiency. It is an improvement on the traditional manual blister sealer, with an enlarged mold size and the introduction of precision sealing timer and cylinder sealing technology, making the sealing process easier and providing sufficient sealing pressure, effectively extending the shelf life of the internal capsules or tablets. The machine uses an intelligent temperature controller to ensure precise temperature control, and has an easy-to-use operation panel and a long-life high-quality electric heating rod.

In addition, the ABM-I is made of aluminum alloy material and a lightweight handle design for easy movement; it is equipped with a protective cover to prevent burns or other injuries during operation; and it provides an optional steel stamp function for printing production batch numbers and dates. Replacing molds does not require disassembly of parts, which simplifies the operation process and is very suitable for environments such as laboratories, hospitals and clinics that require high precision and efficient production.

Description

The ABM-I is a versatile, semi-automatic blister packing machine crafted for small pharmaceutical factories, healthcare plants, and food industry settings. It’s ideal for packaging solid products such as capsules, tablets, gelatin pearls, suppositories, milk tablets, candy, and hardware.

Highlighted Features

- Convenient Sealing: Utilizes a cylinder for efficient sealing, ensuring strong sealing pressure.

- User-Friendly Operation: Simple panel design makes it easy to operate.

- Durable Construction: Incorporates high-quality electrical heating bars for a longer service life.

- Accurate Temperature Control: Equipped with an intelligent temperature controller.

- Compact and Portable: Lightweight with an aluminum alloy build and handle for easy movement.

- Enhanced Safety: Includes a protective cover to prevent injuries during operation.

- Customizable Printing: Optional steel stamp for batch numbers and dates.

- Quick Mold Changes: Easy to change molds without disassembling parts.

- Improved Efficiency: Enhanced mold and pneumatic features boost production speed and quality.

- Safety and Precision: Protective features and accurate temperature control ensure reliable performance.

- Easy Maintenance: Simplified design allows for quick maintenance and mold changes.

Specifications

| Model | ABM-I |

|---|---|

| Max. Heating Area | 135×115 mm |

| Heating Temperature | 90-150℃ |

| Heating Time | 3-6 seconds |

| Air Pressure | 0.6-0.8 MPa |

| Air Displacement | 0.12 m³/min |

| Air Supply Port Diameter | 10 mm |

| Power | 1000 W |

| Power Supply | 110V 60Hz / 220V 50Hz |

| Dimensions | 320×300×375 mm |

| Weight | 21 kg |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288