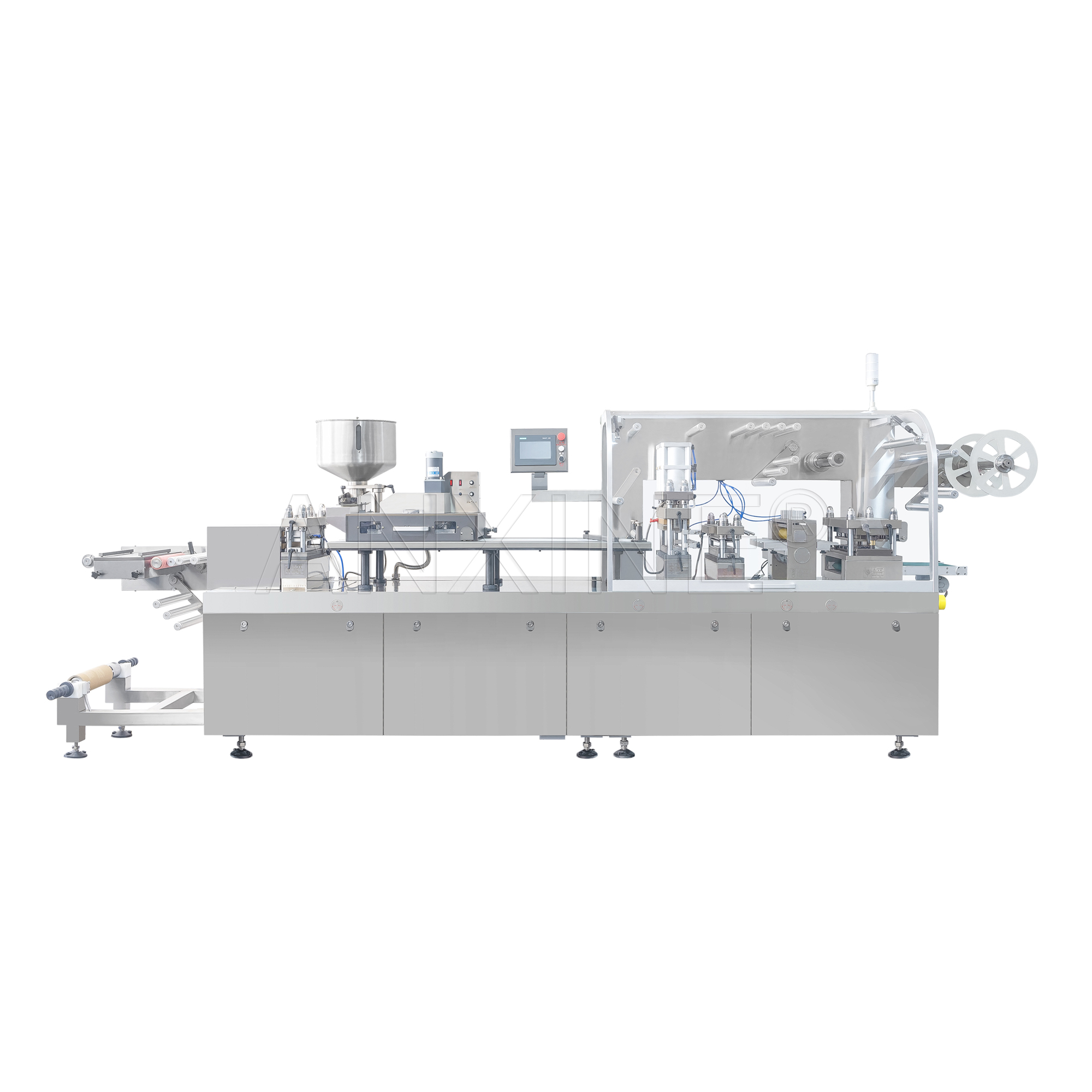

Blister Packing Machine DPP-260

Blister Packing Machine for Optimal Pharma and Food Packaging DPP-260

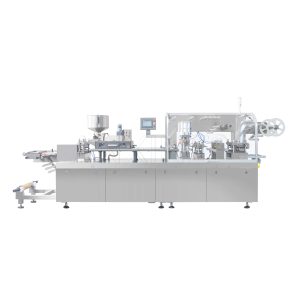

The DPP-260 blister packaging machine is a cutting-edge packaging solution designed for precise and efficient blister packaging of pharmaceutical, chemical and food products. The machine incorporates advanced mechanical, electrical, optical and pneumatic control technologies and strictly follows GMP standards to meet the stringent requirements of the pharmaceutical industry. It is suitable for medium and large pharmaceutical companies, health products and food industries.

The DPP-260 automates key processes, including PVC blister forming, automatic material filling, PTP aluminum foil heat sealing, batch number printing and waste recycling, and can adapt to aluminum-plastic and aluminum-aluminum blister packaging of solid products such as tablets and capsules. Its multifunctional design ensures operational flexibility and wide applicability, providing users with an integrated and efficient packaging platform.

Description

The DPP-260 Blister Packing Machine is a cutting-edge packaging solution designed for the precise and efficient blister packaging of pharmaceutical, chemical, and food products. Featuring advanced mechanical, electrical, optical, and pneumatic control technologies, this machine is engineered to meet the rigorous demands of the pharmaceutical industry, conforming to GMP standards. It is ideal for medium to large pharmaceutical companies, healthcare products, and the food industry.

Highlighted Features

- Innovative Design: Open layout and modular workstation design allow for easy maintenance and adjustment, enhancing operator safety.

- Smart Safety and Detection: Includes heating plate temperature control, overload protection, and material position detection, with automatic fault protection and shutdown.

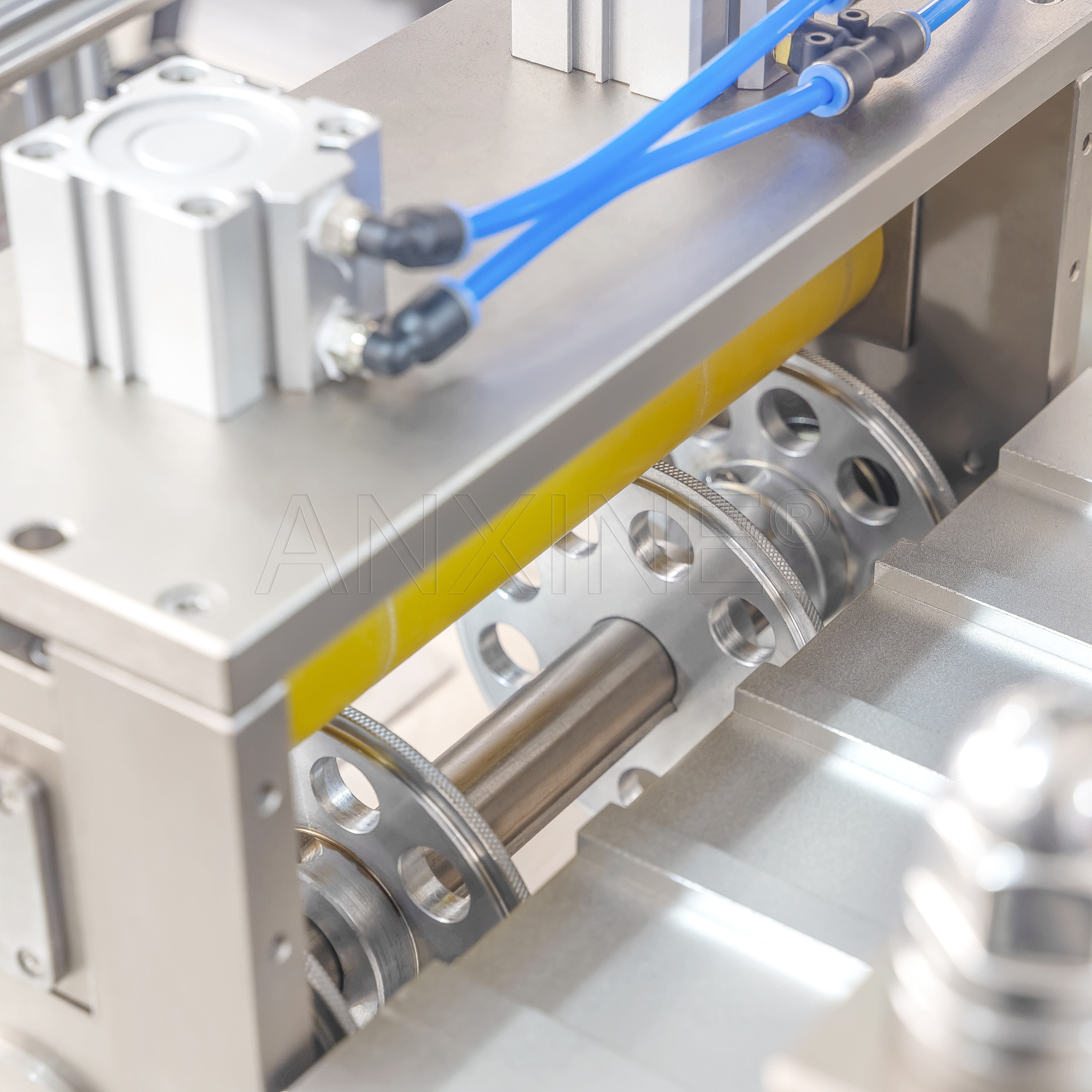

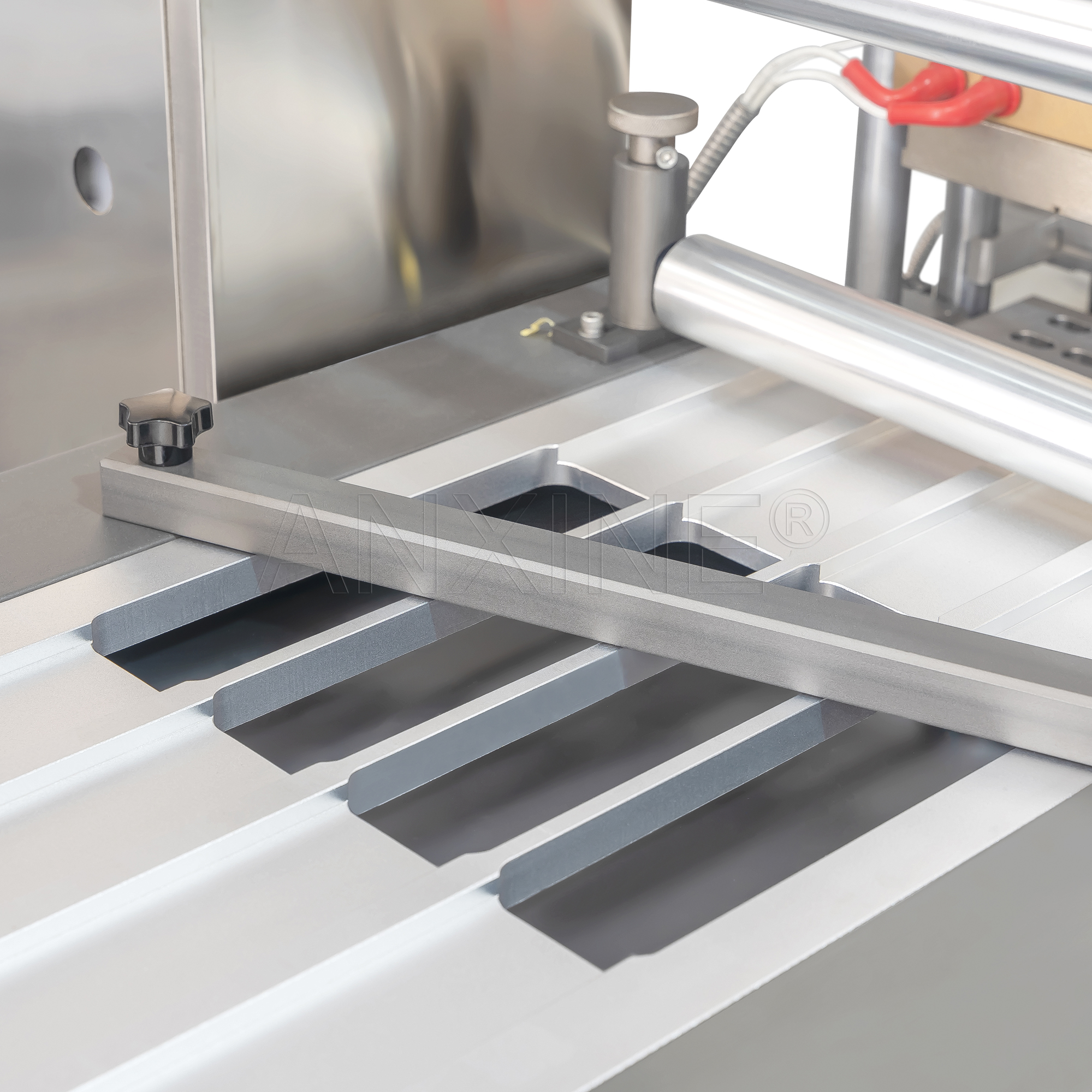

- Efficient Heating Mechanism: Contact-type graphic alignment heating minimizes waste and reduces energy consumption, enhancing plastic plate stability.

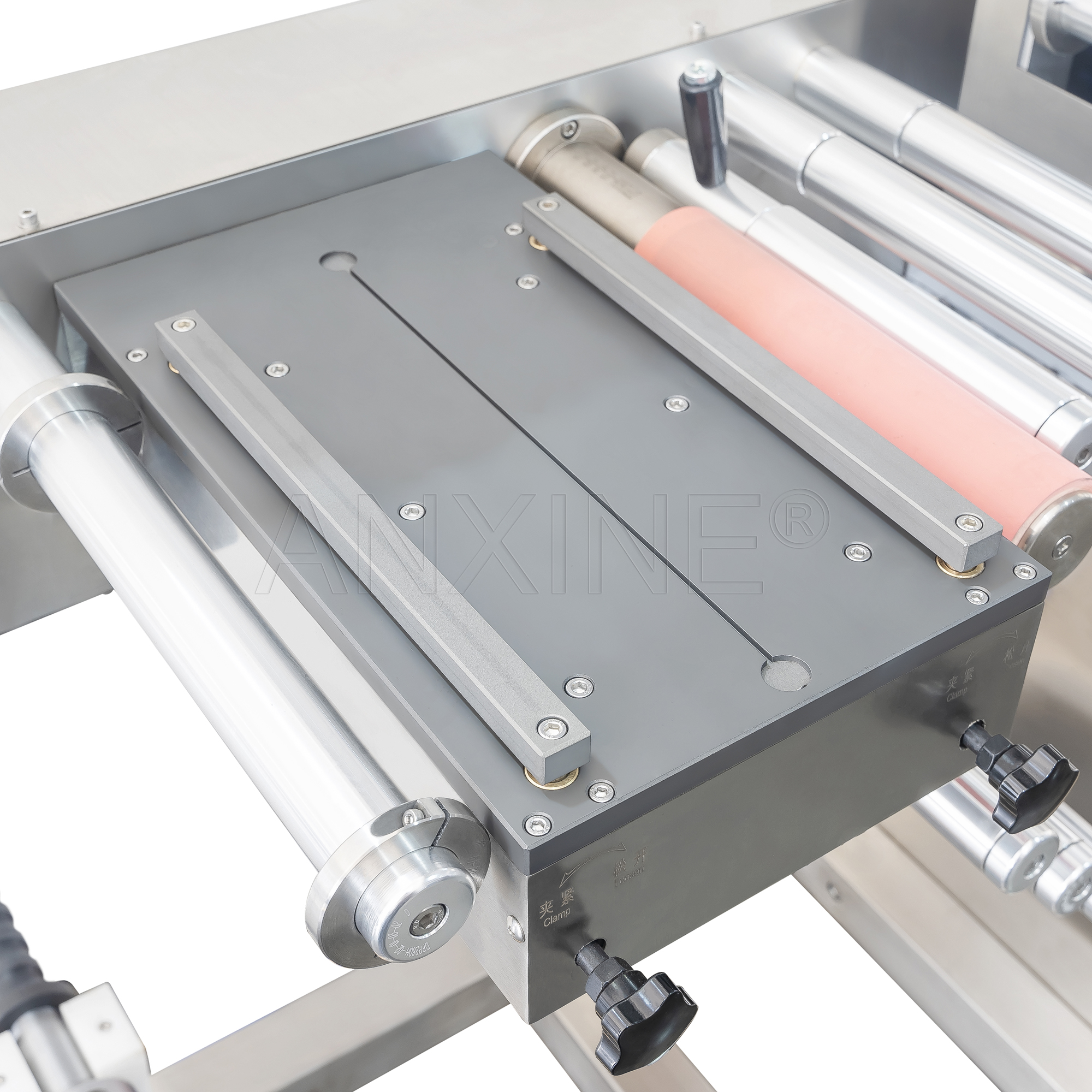

- Quick Change Platform: Enlarged PVC bearing and quick material receiving platforms facilitate rapid adjustments.

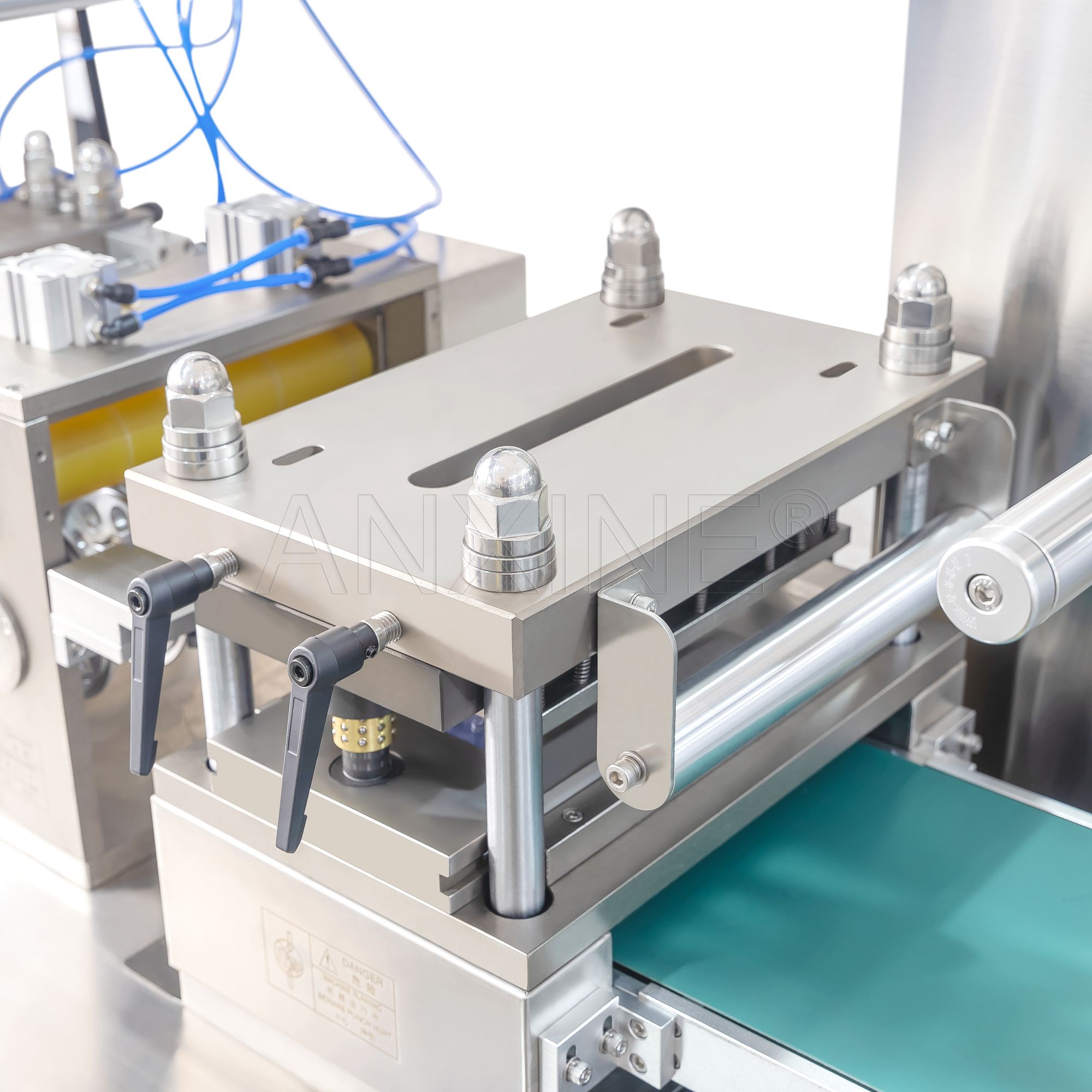

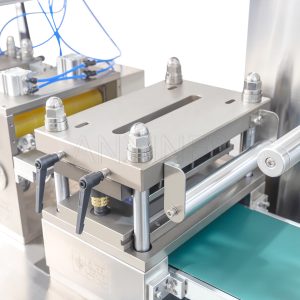

- Easy Mold Replacement: Trapezoidal mold positioning and positive pressure forming simplify replacement, offering high-quality stainless steel construction.

- Air Cushion Sealing: Automatic cylinder-raising mesh plate during stops prevents blister deformation and facilitates cleaning.

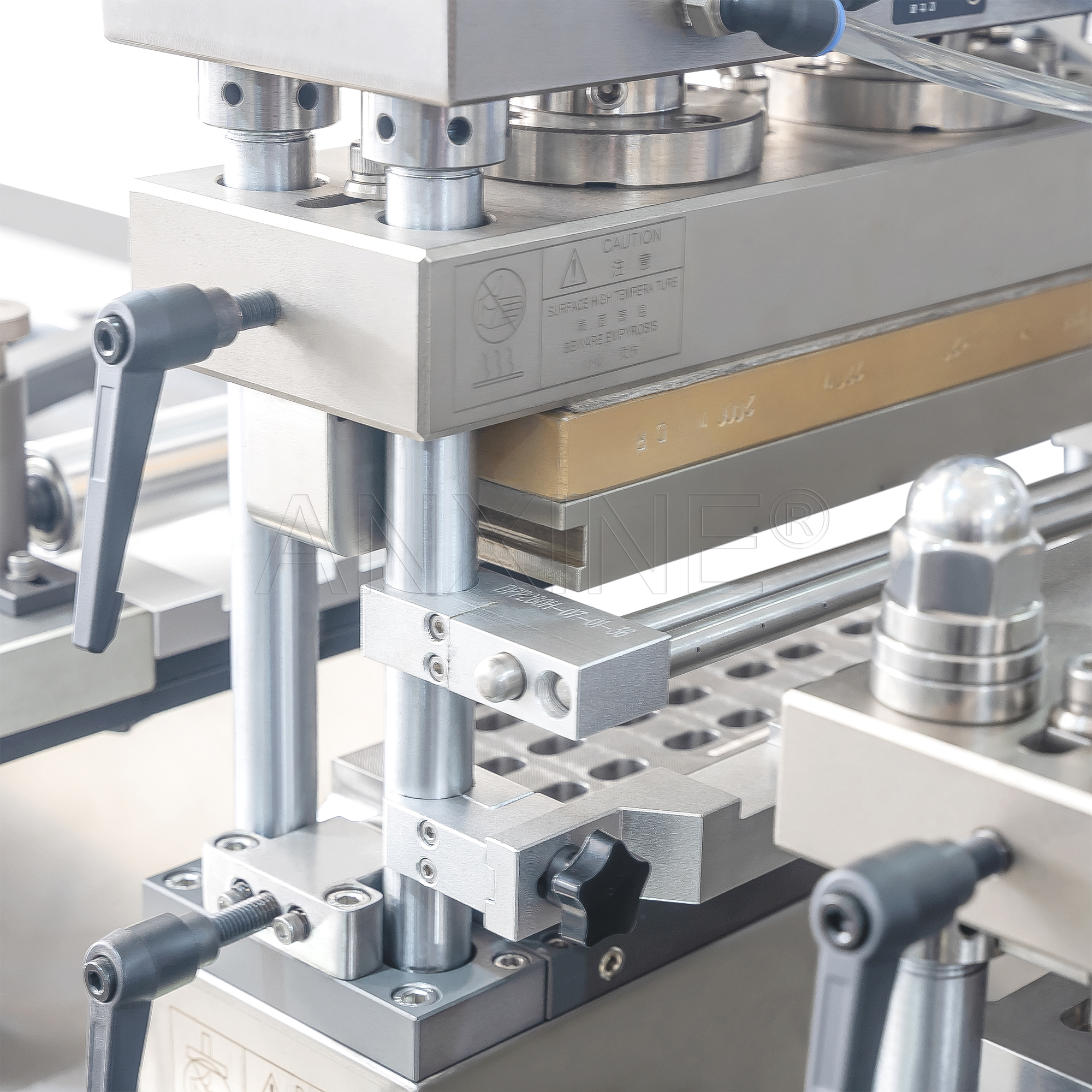

- Advanced Sealing: Male and female mesh plates with point or line patterns for improved sealing and flatter products.

- Enhanced Batch Numbering: Independent batch number printing station ensures clarity and avoids issues from switching molds.

- High-End Control System: PLC control with touch screen operation offers easy monitoring, variable frequency speed regulation, and precise servo traction adjustments.

- Waste Collection: Efficient collection of defective and waste materials ensures a tidy operation environment.

Specifications

| Model | DPP-260 |

|---|---|

| Cutting Frequency | Alu-plastic:precision leadscrew≤50 Alu-al packing:≤30 |

| Max Forming Area | 250×180 mm |

| Max Forming Depth | Alu-plastic:26 Alu-Alu:14 |

| Travel Range | 0-180 mm |

| Standard Plate | 80×57 mm (customizable) |

| Air Pressure | 0.4-0.6 Mpa |

| Power Supply | 380V/220V 50Hz 6.2 kW |

| PVC Hard Pieces | 0.15-0.5×260 mm |

| PTP Aluminum Foil | 0.02-0.035×260 mm |

| Dialysis Paper | 50-100 g×260 mm |

| Mould Cooling | Tap or back water |

| Dimensions | 3900×730×1600 mm |

| Weight | 1600 kg |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288