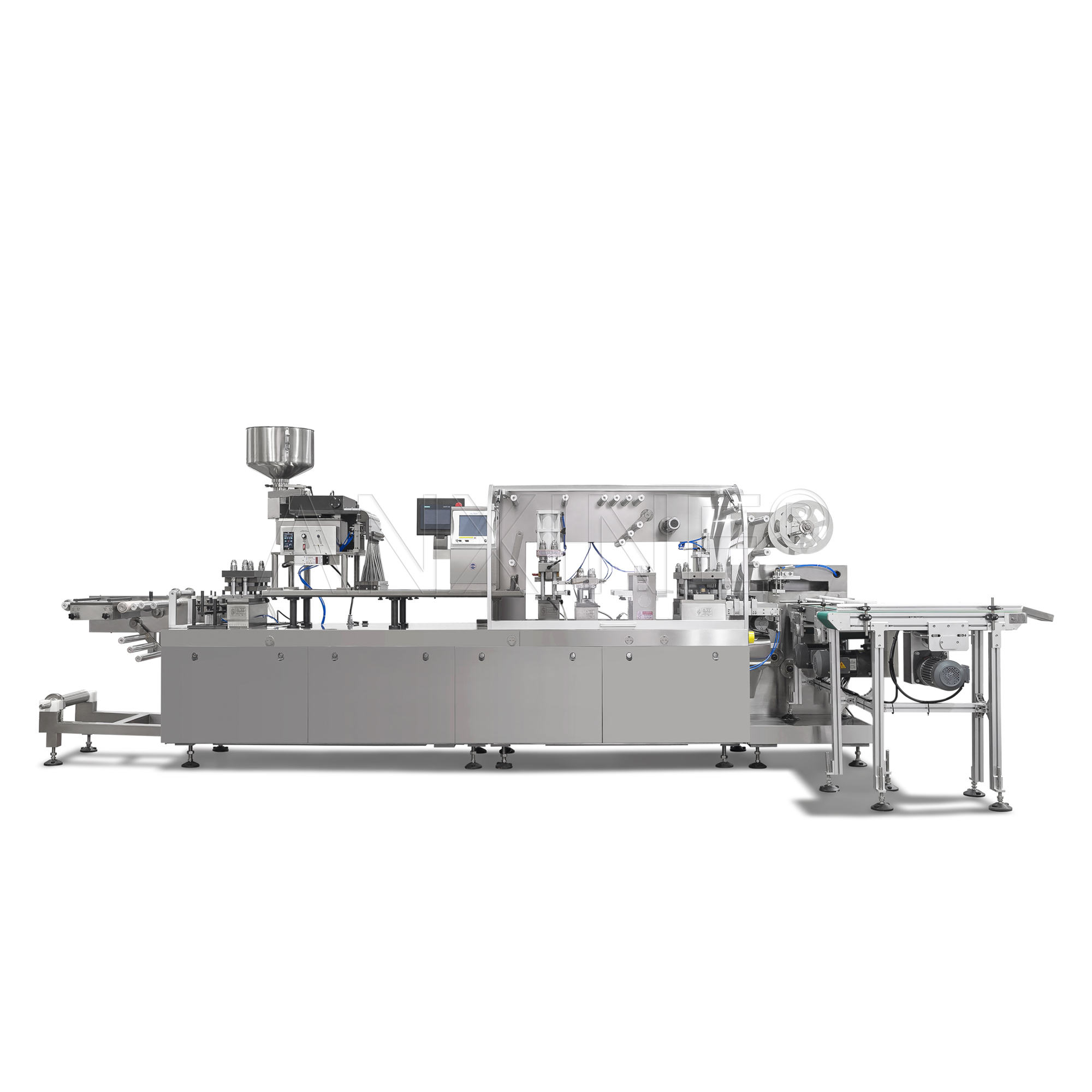

Blister Packing Machine DPP-250

Blister Packing Machine for Efficient Packaging Solutions DPP-250

The DPP-250 blister packaging machine is an advanced flat-bed blister packaging system designed for the packaging of pharmaceuticals, foods and electronic components in Alu-PVC and Alu-Alu materials. This machine is ideal for use in hospital dosage rooms, laboratories and small and medium-sized pharmaceutical factories. It is easy to operate, versatile and durable.

The DPP-250 integrates multiple functions such as PVC feeding, thermoforming, PTP feeding, sealing, and uses positive pressure forming and flat-bed hot-pressing sealing technology to ensure smooth and uniform blister sheets. In addition, the machine is equipped with advanced features such as pre-cut detection, printed mark alignment and automatic feeding system to improve efficiency and precision to meet the needs of high-quality packaging. By integrating these advanced technologies, the DPP-250 provides excellent packaging solutions while ensuring efficient operation to adapt to a variety of production needs.

Description

The DPP-250 Blister Packing Machine is a state-of-the-art flat-plate blister packaging system, perfect for Alu-PVC and Alu-Alu packaging of pharmaceuticals, foods, and electronic components. Tailored for hospital dosage rooms, laboratories, and small to medium-sized pharmaceutical factories, it offers ease of operation, multifunctionality, and long-lasting durability.

Highlighted Features

- Modular Design: Easily disassembled for transport, with straightforward assembly using cylindrical pins and screws.

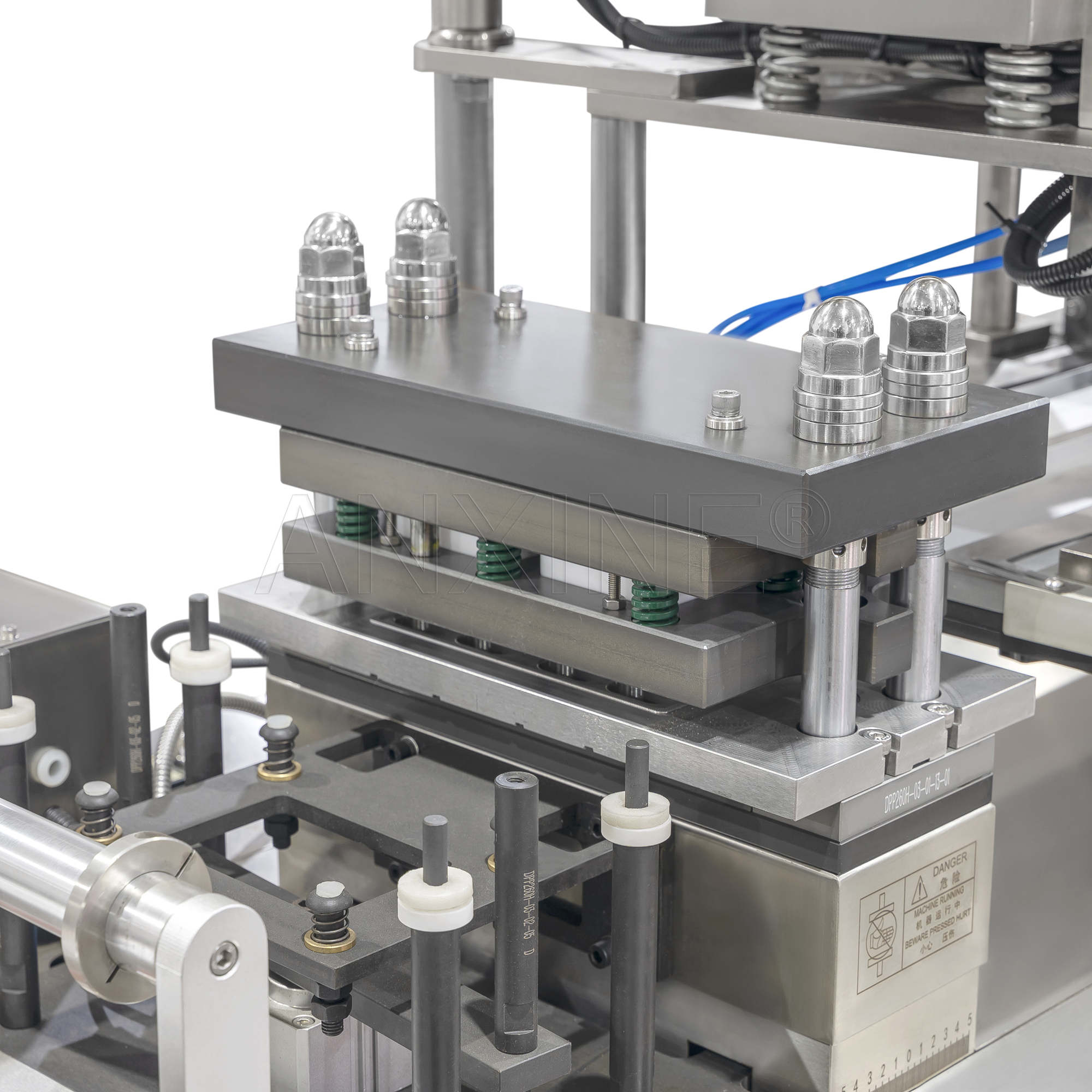

- Convenient Mold System: Molds are pressed and clamped for simple assembly and disassembly.

- Variable Speed Control: Main motor with frequency speed control; up to 50 blanking times per minute.

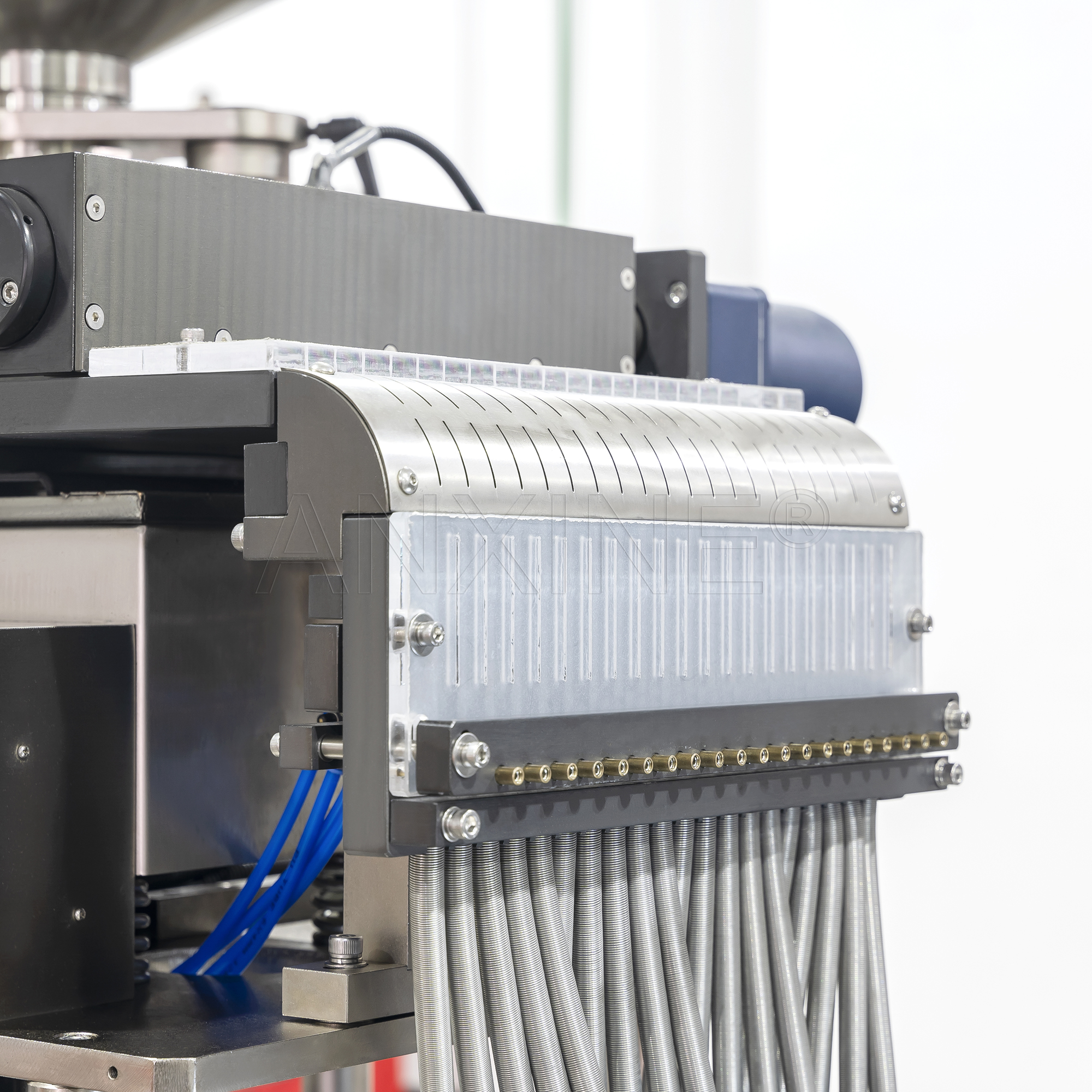

- Precision Traction: Mechanical arm clamping ensures stable operation and precise synchronization.

- Adjustable Stroke Length: Stroke can be adjusted between 30-120 mm for flexible plate sizing.

- Energy Efficiency: Automatic heating plate control reduces energy use and material waste.

- Enhanced Life Span: Heat seal station with a cylinder aids in avoiding deformation and cleaning, while also buffering overpressure.

- Improved Sealing: Upper and lower chequered stripes enhance sealing performance.

- Safety Features: Automatic shutdown and alarm if PVC runs out or breaks, equipped with an emergency stop device.

- GMP Compliance: Constructed with stainless steel and non-toxic materials to meet GMP standards.

Specifications

| Model | DPP-250 |

|---|---|

| Cutting Frequency | 10-50 times/min |

| Capacity | 9600 strips/hour |

| Max Shaping Areas and Depth | Alu-Alu: 240×150×18mm Alu-Pvc: 240×150×27mm (Special model can be 47mm) |

| Travel Range | 40-160 mm (extendable to 180 mm as needed) |

| Standard Plate | 80×57 mm (customizable) |

| Air Pressure | 0.4-0.6 Mpa |

| Power Supply | 380V/220V 50Hz 6.2 kW |

| PVC Hard Pieces | 0.15-0.5×260 mm |

| PTP Aluminum Foil | 0.02-0.035×260 mm |

| Dialysis Paper | 50-100 g×260 mm |

| Mould Cooling | Tap or back water |

| Dimensions | 3000×730×1600 mm |

| Weight | 1600 kg |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288