Rotary Tablet Press ZP-D

Rotary Tablet Press Machine ZP-D

The ZP-D series rotary tablet press is designed for the pharmaceutical and health care products industries, providing efficient and precise tablet pressing solutions. The series includes three different models: ZP-29D, ZP-19D, ZP-17D and ZP-15D, which are suitable for medium and large batch production. They are easy to operate and maintain, and are indispensable key equipment in pharmaceutical production.

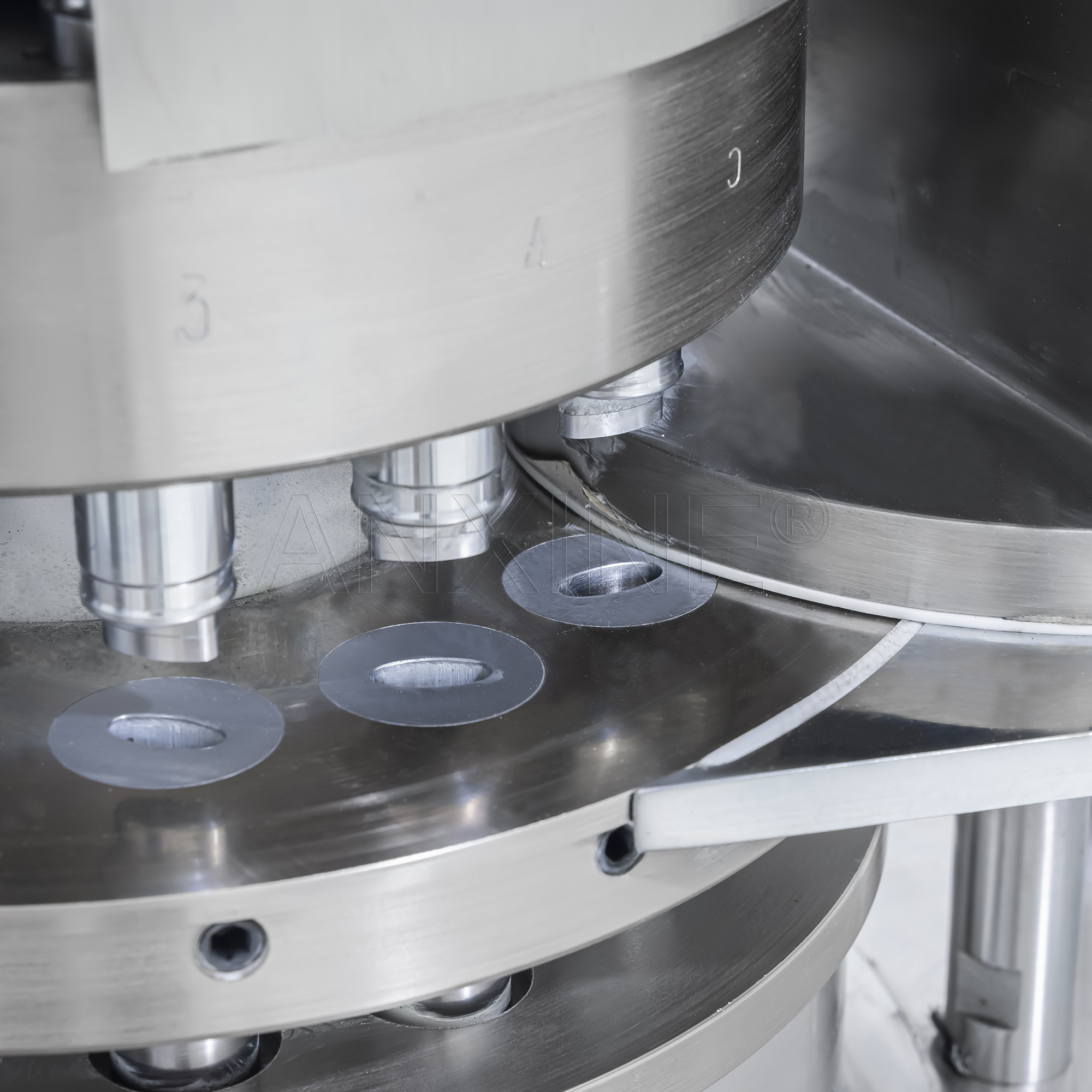

The ZP-D series rotary tablet press adopts advanced rotary working principle and precise control system to ensure the consistency and high quality of each tablet. The machine can flexibly adjust the hardness and thickness of the tablet by adjusting parameters such as pressure and speed to meet the quality requirements of different products. Each model is equipped with a user-friendly HMI touch screen interface, supports multi-language selection, provides a simple operation experience, and is strictly designed and manufactured in accordance with the Good Manufacturing Practice (GMP) to ensure sanitary conditions and safety. The modular structure design facilitates cleaning and replacement of parts, reducing downtime and maintenance costs. Not only suitable for medium and large batch production, but also can be used for laboratory research and development and teaching training. It is an indispensable quality control tool in modern pharmaceutical production lines.

Description

The ZP-D Rotary Tablet Press is a fully automated, continuous tablet pressing machine. It is designed for converting various granular materials into tablets, but is not suitable for semi-solid, moist powders, or non-granular superfine powders. It is predominantly used across pharmaceutical, chemical, ceramic, food, electronic, plastic, and powder metallurgy industries.

Highlighted Features

- Efficient Design: Utilizes rolling friction on pressing wheels to minimize resistance and power loss.

- Centralized Controls: Easy adjustment and control of filling amount, tablet thickness, and rotation speed.

- Durability: Features an enclosed oil-immersed worm gear drive for reduced power loss and extended worm gear life.

- Hygienic Operation: Fully enclosed structure with a sealed pressing chamber, preventing dust and cross-contamination of oil.

- Effective Dust Collection: Comes with an independent vacuum cleaner for efficient dust collection, ensuring smooth operation.

Specifications

| Model | ZP-15D | ZP-17D | ZP-19D | ZP-29D |

|---|---|---|---|---|

| Punch quantity | 15 Set | 17 Set | 19 Set | 29 Set |

| Max Tablet Pressure | 60KN | 60KN | 60KN | 80KN |

| Max Tablet Diameter | 22 mm | 20 mm | 13 mm | 25 mm |

| Max Tablet Thickness | 6 mm | 6 mm | 6 mm | 6 mm |

| Max Filling Depth | 15 mm | 15 mm | 15 mm | 15 mm |

| Max Production Capacity | 35,000 pc/h | 40,000 pc/h | 42,000 pc/h | 12,5000 pc/h |

| Depth of Middle Punch | 22 mm | 22 mm | 22 mm | 22 mm |

| Diameter of Middle Punch | 34 mm | 30 mm | 26 mm | 26 mm |

| Diameter of Upper and Lower Punch | 26 mm | 22 mm | 22 mm | 22 mm |

| Length of Upper Punch | 115 mm | 115 mm | 115 mm | 115 mm |

| Length of Lower Punch | 115 mm | 115 mm | 115 mm | 115 mm |

| Overall Dimensions | Length: 615mm Width: 890mm Height: 1,415mm Weight: 1,000kg |

Length: 615mm Width: 890mm Height: 1,415mm Weight: 1,000kg |

Length: 615mm Width: 890mm Height: 1,415mm Weight: 1,000kg |

Length: 1,230mm Width: 950mm Height: 1,670mm Weight: 1,700kg |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288