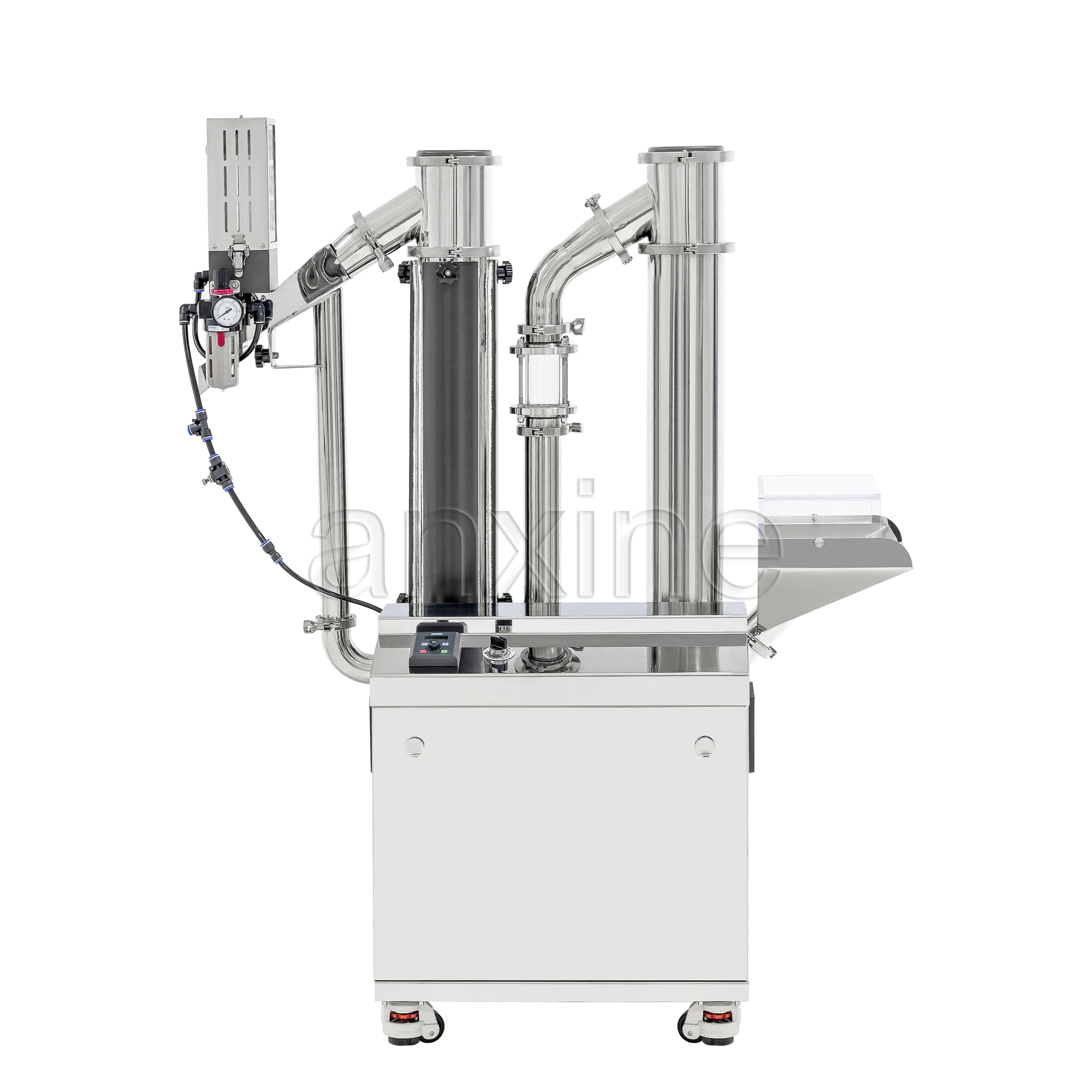

Double Uphill Elevating Capsule Polisher and Sorter ACP-200V

Double Uphill Elevating Capsule Polisher and Sorter ACP-200V

ACP-200V is an efficient capsule polishing and sorting equipment designed for the pharmaceutical and health care products industries, combining advanced polishing technology and intelligent sorting system. The machine adopts an innovative brush roller design to provide excellent polishing effect without damaging the capsules; the built-in high-precision visual inspection system automatically identifies and removes broken, deformed or abnormally colored capsules to ensure that only qualified products enter the next production link. In addition, ACP-200V has a unique loading function that can directly lift capsules from below to the polishing and sorting station, simplifying the operation process.

The equipment is equipped with a user-friendly HMI touch screen interface and supports multi-language selection, which is convenient for global application. It is designed and manufactured in strict accordance with the Good Manufacturing Practice (GMP) of pharmaceutical production to ensure sanitary conditions and safety; the modular structure design facilitates cleaning and replacement of parts, reducing downtime. It is suitable for capsules of various specifications and types, meeting diverse production needs, and is an indispensable quality control tool in modern capsule production lines. Its large-capacity processing capacity and fully automated operation are particularly suitable for large-scale production and continuous operation, improving overall production efficiency.

Description

The ACP-200V Capsule Polisher is a cutting-edge machine designed for capsule polishing and elevating. It connects seamlessly with capsule filling machines, sorters, and metal detectors, ensuring a streamlined production process from polishing to defect detection.

Highlighted Features

- Dual Functions: Provides both polishing and elevating to enhance production adaptability.

- Versatile Integration: Easily connects to capsule filling machines and integrates with sorters and metal detectors.

- High Efficiency: Capable of processing up to 600,000 capsules per hour.

- Automatic Sorting: Identifies and removes capsules with low dosage, empty shells, fractures, and cap-body separation.

- Adjustable Design: 360° adjustment for inlet and outlet ensures flexibility and convenience in production.

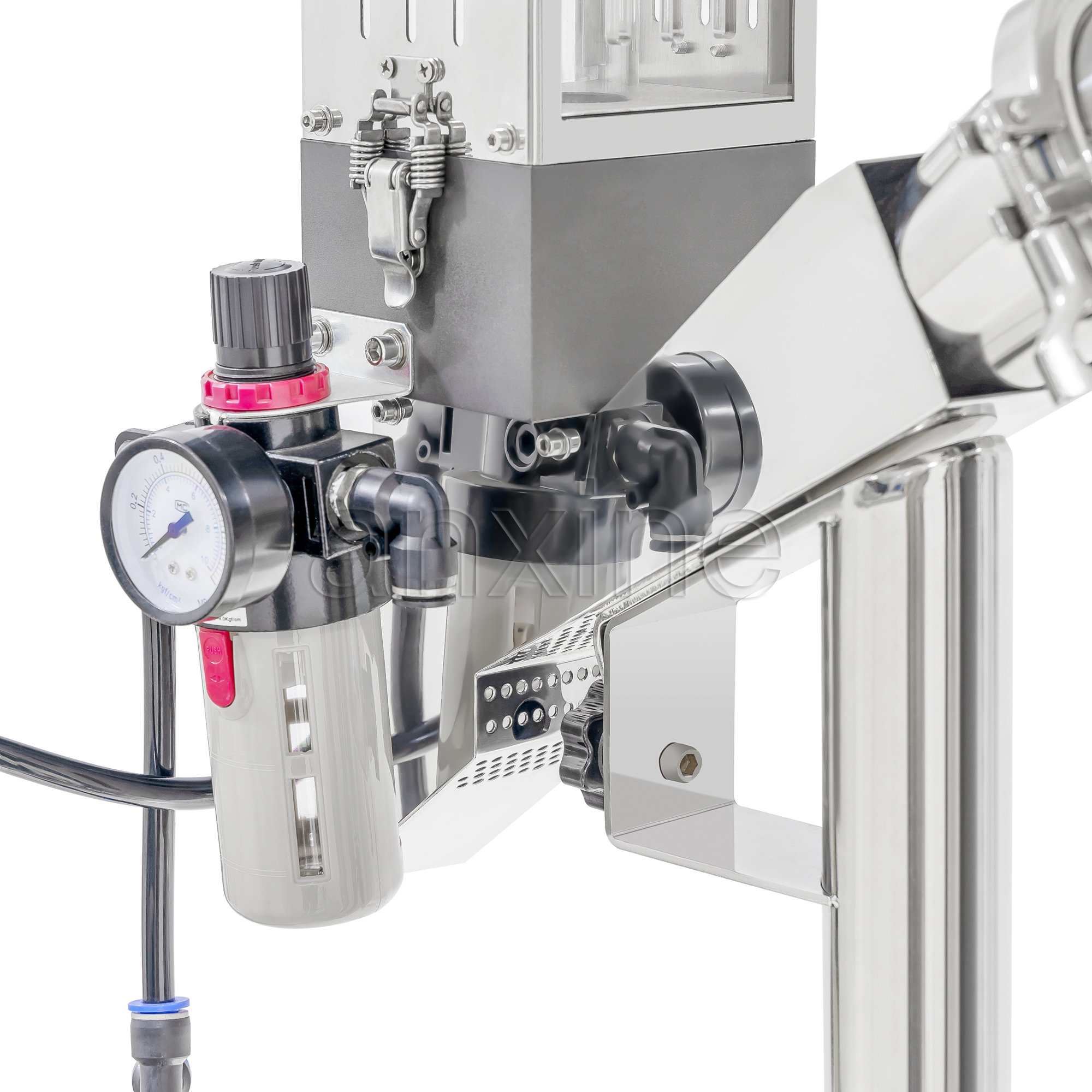

- Easy Maintenance: Fast-joint system allows for quick disassembly and cleaning; detachable main shaft brush ensures comprehensive cleaning without blind spots.

- Premium Construction: Contact parts made from 316L stainless steel, conforming to modern medicinal safety standards.

- Compliance: Designed to meet cGMP requirements.

Specifications

| Model | ACP-200V |

|---|---|

| Application | Suitable for polishing and sorting all capsule types. |

| Max Output | 600,000 pcs/h |

| Capsule Sizes | Compatible with sizes 00#, 0#, 1#, 2#, 3#, 4# |

| Power Supply | 1PH 220V/110V 50Hz/60Hz, 0.2 kW |

| Inlet Height | 750mm Size: 300 x 250 mm |

| Outlet Height | 1005mm Size: 65 x 50 mm |

| Overall Dimensions | Length: 1,229mm Width: 709mm Height: 1,489mm Weight: 80kg |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288