Automatic Dropper Bottle Filling & Cap Screwing Machine CGS-1

Automatic Dropper Bottle Filling & Cap Screwing Machine CGS-1

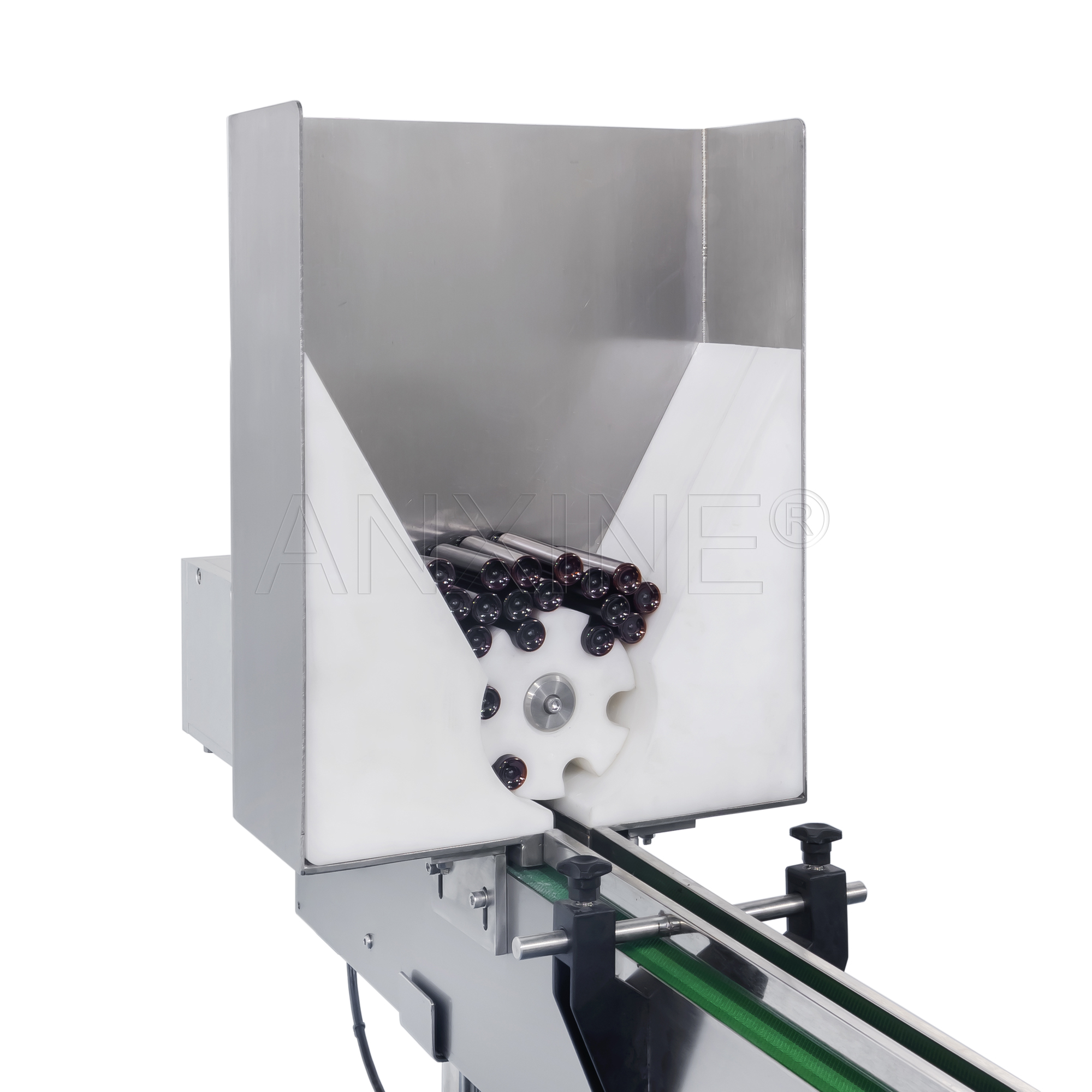

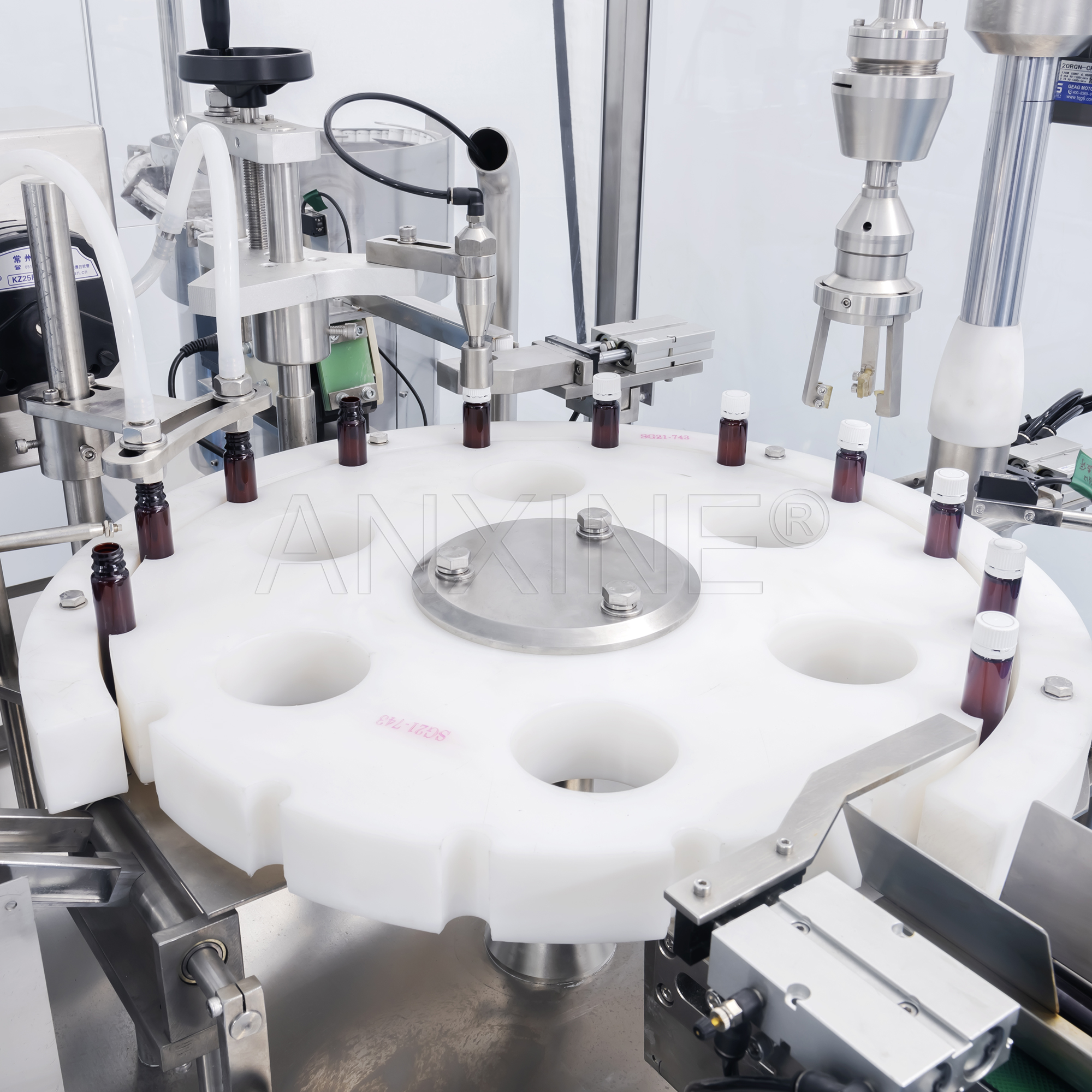

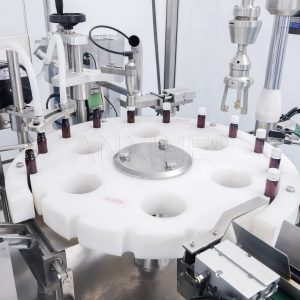

The CGS-1 is an advanced machine specifically designed for the efficient filling and capping of moderate-dose bottles, boasting a compact yet robust structure that ensures seamless integration into existing production lines. This innovative equipment features an intelligent system for bottle sorting and loading through the use of rollers, which guides each container accurately into position. For precise filling operations, the CGS-1 employs a peristaltic pump that delivers consistent dosages while the bottles are held in a fixed disc position, guaranteeing accuracy and reliability. Caps are meticulously sorted using a vibration mechanism before being securely applied by rotating heads, ensuring a tight seal every time.

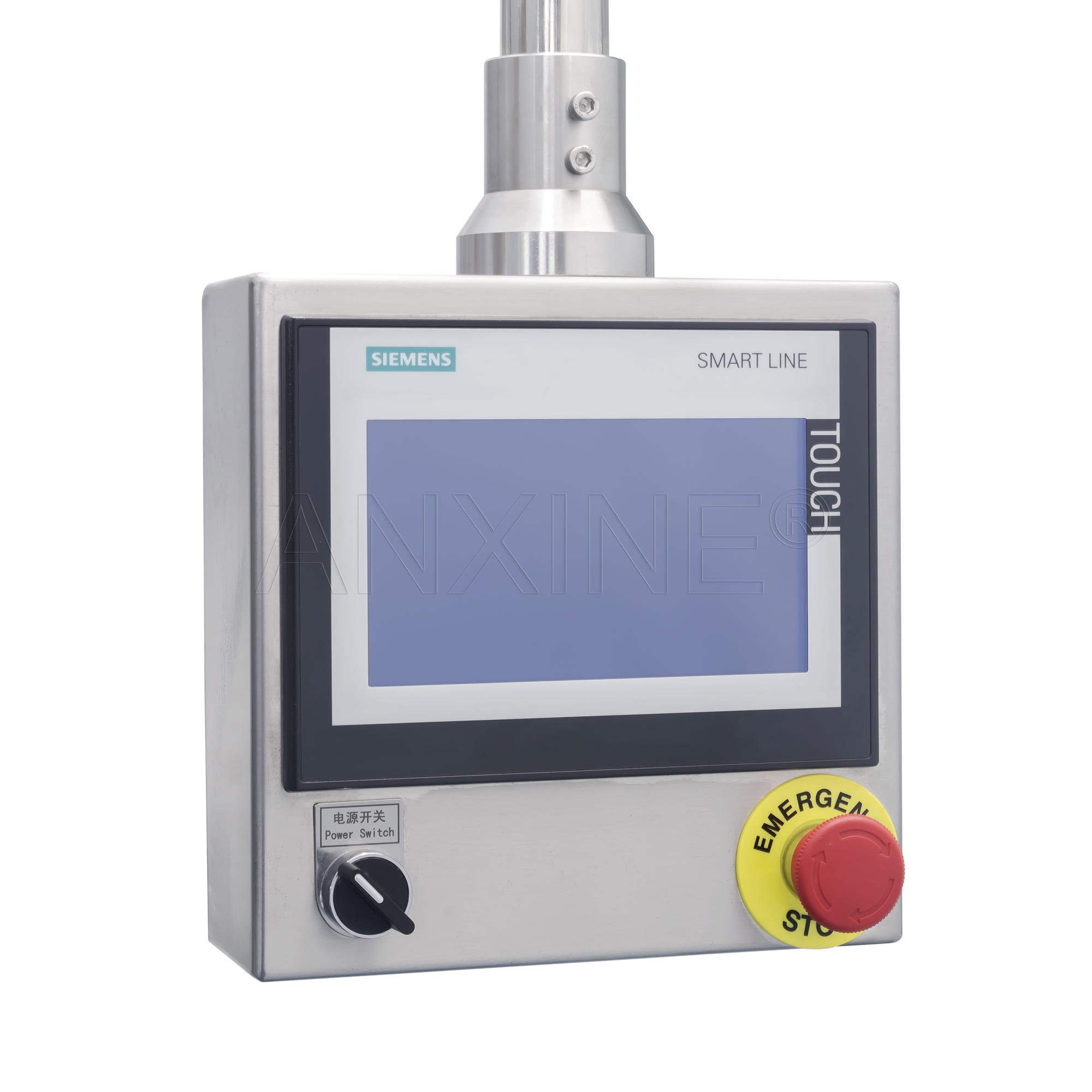

The streamlined design of the CGS-1 not only simplifies maintenance but also enhances connectivity with other production components, promoting a harmonious workflow within the manufacturing environment. Its high-quality construction and user-friendly interface make the CGS-1 an indispensable asset for industries seeking to optimize their packaging processes with precision, efficiency, and ease.

Description

The CGS-1 is designed for efficient filling and capping of moderate-dose bottles, with a compact structure that allows for easy integration into production lines.

The CGS-1 machine is equipped to handle bottle sorting and loading using rollers, and utilizes a peristaltic pump for precise filling in a fixed disc position. Caps are sorted via vibration and secured using rotating heads. Its streamlined design facilitates easy maintenance and connectivity with other production equipment.

Highlighted Features

- Efficient Loading and Filling: Utilizes rollers for bottle sorting and loading; peristaltic pump ensures precise filling.

- Vibrating Cap Sorting: Cap sorting disc vibrates to position caps for efficient screwing.

- Compact Design: Facilitates easy maintenance and integration with additional equipment.

- Durable Construction: Made with PC board and 304 stainless steel frame for robustness and safety.

- Smooth Operation: Equipped with a protective structure to ensure safety and hygiene.

- Maintenance Alerts: Regular maintenance requirements include lubrication checks and tightening of fasteners to ensure optimal operation.

Specifications

| Model | CGS-1 |

|---|---|

| Production Capacity | 1500-1800 bottles/hour |

| Air Pressure | 0.5-0.8 MPa |

| Air Volume | 25-27 m³/h |

| Power Supply | 220V 50Hz |

| Total Power | 2 kW |

| Weight | Approximately 800 kg |

| Dimension | 3,500 mm × 2,850 mm × 1,750 mm |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288