Automatic Dropper Bottle Filling & Cap Screwing Machine C4DY-2

Automatic Dropper Bottle Filling & Cap Screwing Machine C4DY-2

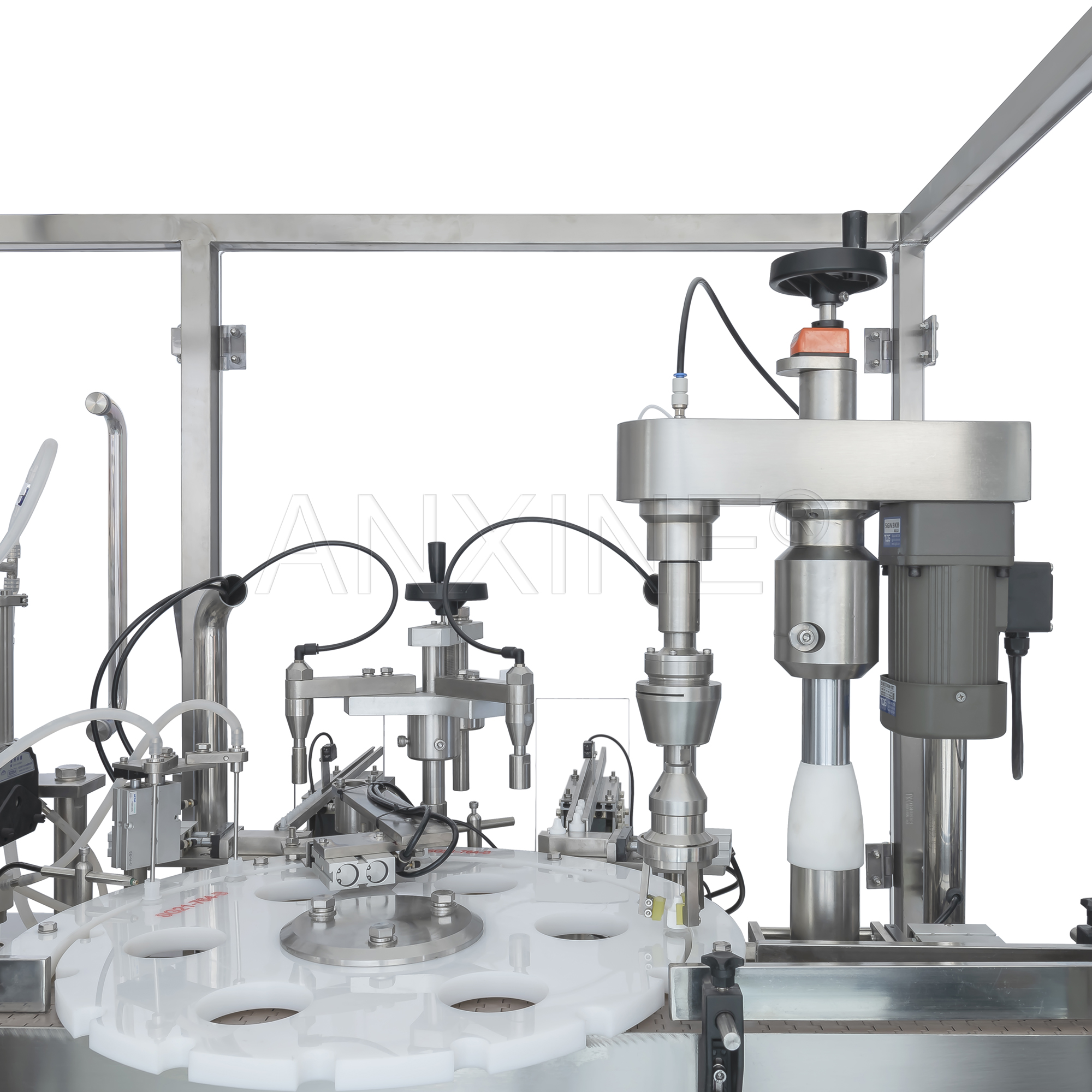

The C4DY-2 medium-dose bottle filling machine is meticulously engineered to offer unparalleled flexibility with its dual filling methodologies, incorporating both a four-head piston pump for accurate volume control and a double-head peristaltic pump for handling more sensitive or viscous materials. This innovative design not only accommodates a wide range of product viscosities but also ensures adaptability across various bottle sizes, making it an ideal addition to diverse production lines. The machine’s compact footprint facilitates seamless integration into existing setups without requiring extensive modifications. During the capping process, bottles remain stationary, which significantly enhances the precision of cap placement and screwing.

Constructed with durability and hygiene in mind, the C4DY-2 features critical components such as the metering pump and filling heads made from high-quality SAE 316L stainless steel, known for its superior corrosion resistance and ease of cleaning. Safety is prioritized through the inclusion of a protective cover fabricated from robust PC board material, complemented by a sturdy 304 stainless steel frame that encases the machinery. This combination of features makes the C4DY-2 a reliable and efficient choice for pharmaceutical, cosmetic, and food industries seeking to optimize their filling processes while maintaining stringent quality standards.

Description

The C4DY-2 is designed for medium-dose bottle filling, offering flexibility with two distinct filling methods. Its compact design allows easy integration into production lines, making it suitable for various bottle sizes.

Highlighted Features

- Versatile Filling Options: Supports both piston and peristaltic pump filling methods for flexibility.

- High Precision: Ensures accurate filling with bottles fixed in position during processing.

- Sturdy Construction: Made with SAE 316L stainless steel for durability and hygiene.

- Production Line Integration: Easily integrates with other equipment for streamlined production.

- Protective Cover: Features safety covers to protect users and maintain a clean environment.

- Air Pressure Requirement: Requires an external air storage tank (200-300L) for stable air pressure and optimal pneumatic component performance.

Specifications

| Model | C4DY-2 |

|---|---|

| Production Capacity | 30 bottles/min (four-head filling) |

| Air Pressure | 0.5-0.8 MPa |

| Air Volume | 13-15 m³/h |

| Power Supply | 220V 50Hz |

| Total Power | 3 KW |

| Weight | 950 Kg |

| Dimension | 2,400 × 1,650 × 1,700 mm |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288