Fully Automatic Vial Filling & Capping Machine CGZ-4

Fully Automatic Vial Filling & Capping Machine CGZ-4

The CGZ-4 automatic glass bottle filling and capping machine is designed for small batch production and is suitable for industries such as medicine, light chemical industry and food. The equipment can complete a series of automated steps, including bottle feeding, metering filling, plug pressing and sealing cover installation, ensuring efficient and accurate production and product quality.

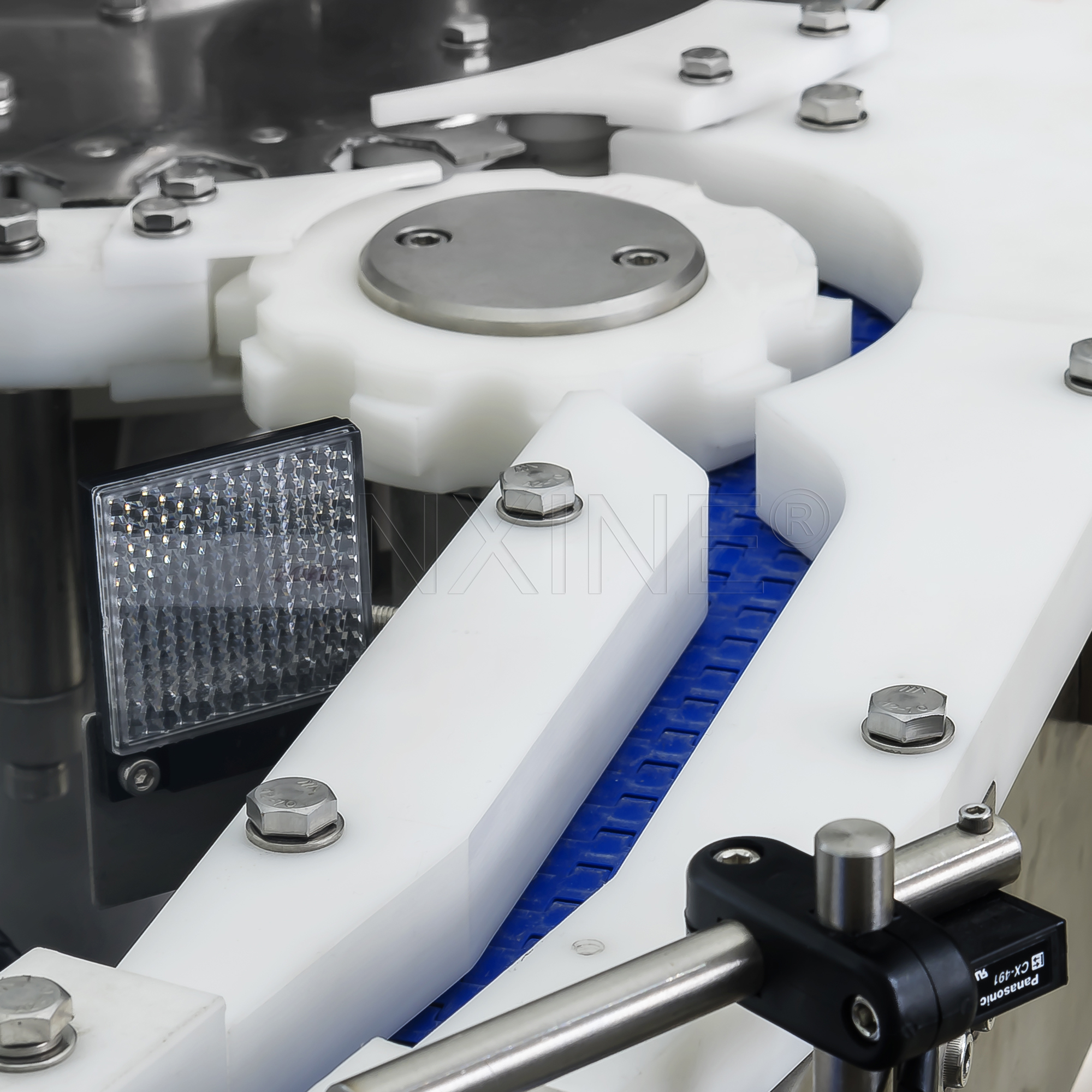

The CGZ-4 automatic glass bottle filling and capping machine is made of 304 stainless steel, which has strong corrosion resistance, and is equipped with a programmable logic controller (PLC) and a human-machine interface (HMI), making it easy to operate and easy to control. The application of servo motor drive system and peristaltic pump filling technology ensures high precision, fast speed and high output of the machine. Its unique equal-disc bottle feeding mechanism provides high-precision positioning, while the filling volume of the peristaltic pump can be adjusted within a large range. In addition, the components of the drive system are made of high-quality steel, and the surface treatment prevents oxidation and enhances hardness to extend the service life. The whole machine is also equipped with a 304 stainless steel frame and a protective cover composed of PC transparent plate.

Description

The CGZ-4 model is expertly engineered for small-quantity filling, stopper pressing, and seal capping, tailored for industries such as pharmaceuticals, light chemicals, and food processing. This machine automates vial feeding, metering, filling, stopper pressing, and capping processes.

Highlighted Features

- All-stainless steel structure: The main body is made of 304 stainless steel, which has excellent corrosion resistance.

- Intelligent control system: Use PLC and HMI to simplify the operation process and improve the user experience.

- High-precision servo drive: Ensure the synchronous operation of each moving part and provide a stable working environment.

- Wide range filling adjustment: Accurate filling of different capacities can be achieved by changing the peristaltic pump parameters.

- Efficient feeding mechanism: The specially designed bottle feeding system improves the accuracy of the bottle entry position.

- Safety protection device: Equipped with a transparent protective cover and other necessary safety features to ensure the safety of the operator.

- Convenient maintenance: Key parts are easily accessible for daily maintenance and repair.

- Compact design: Save space without affecting functional integrity.

Specifications

| Model | CGZ-4 |

|---|---|

| Production Capacity | 100~120 vials/min |

| Air Pressure | 0.5~0.8 MPa |

| Air Consumption | 8~10 m³/h |

| Power Supply | 380V, 50Hz |

| Total Power | 3.5kW |

| Weight | 500kg |

| Dimension | 2,000×1,100×1,800 mm |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288