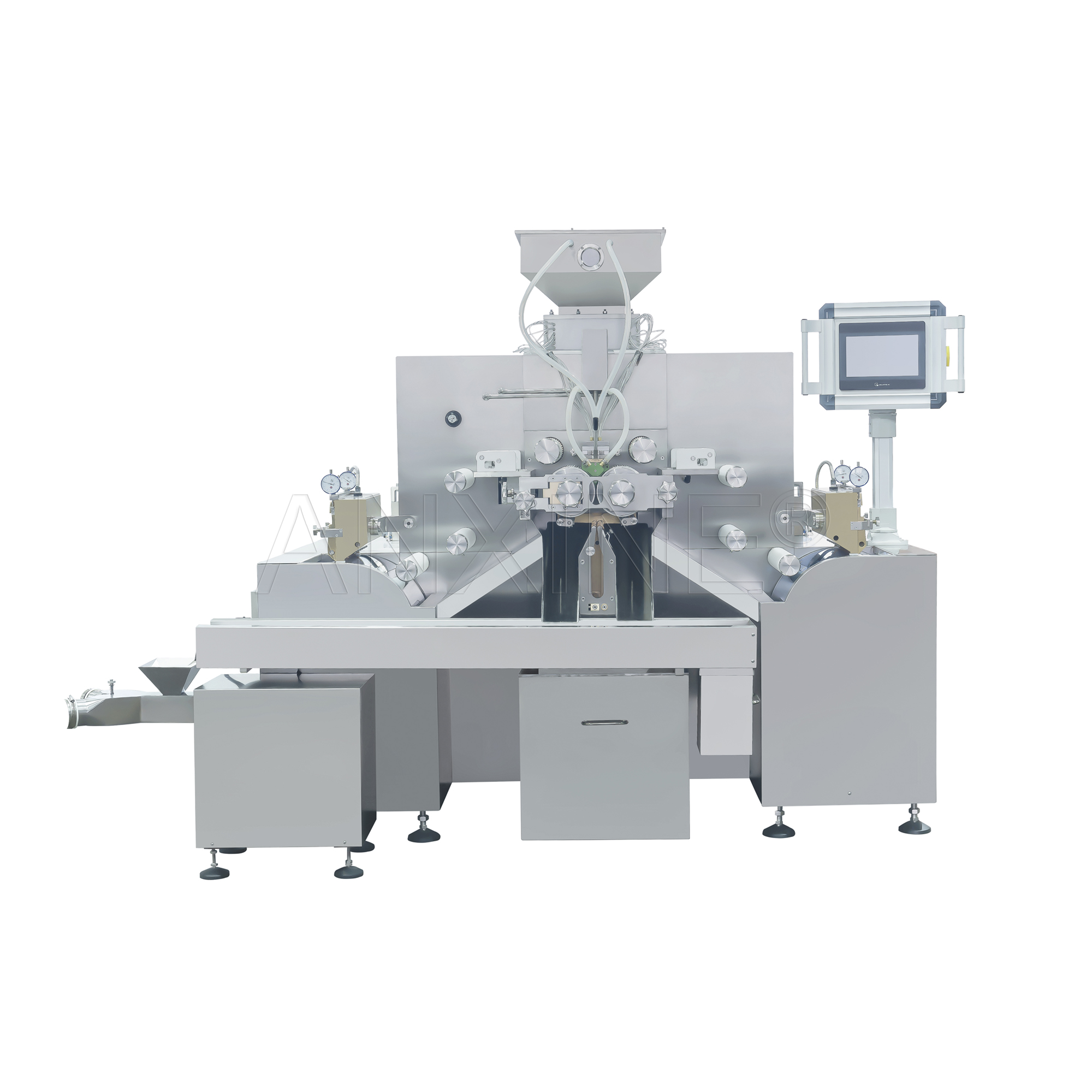

Liquid R&D Softgel Capsule Gel Oil Filling Machine ASE-200C

Liquid R&D Softgel Capsule Gel Oil Filling Machine ASE-200C

The ASE-200C Softgel Encapsulation Machine is a high-tech solution that enables the precise injection of oil, mixing suspensions, and pastes into capsules — forming softgel capsules of varying sizes, shapes, and colors. With a high-speed disintegration feature, our capsules are conveniently designed to offer easy oral administration, oxygen resistance, and easy storage.

This machine is recognized for its high productivity, precise filling, quality stability, and high end-product rate, making it the preferred choice for manufacturers in the medicine, health products, cosmetics, and paintball industries.

The ASE-200C has passed provincial-level evaluations for new products and EU certification. It also incorporates two patented technologies that showcase its exquisite craftsmanship.

Description

Unlock the efficiency of capsule production with the ASE-200C, a state-of-the-art softgel encapsulation machine renowned for its precision, quality assurance, and high output.

Highlighted Features

- High production capacity: The machine has excellent production efficiency and can produce approximately 370 million granules per year (based on 200C model, No. 8 oval, at a speed of 3 revolutions per minute, 24 hours a day, 300 days a year). This efficient production capacity ensures that the needs of large-scale production are met.

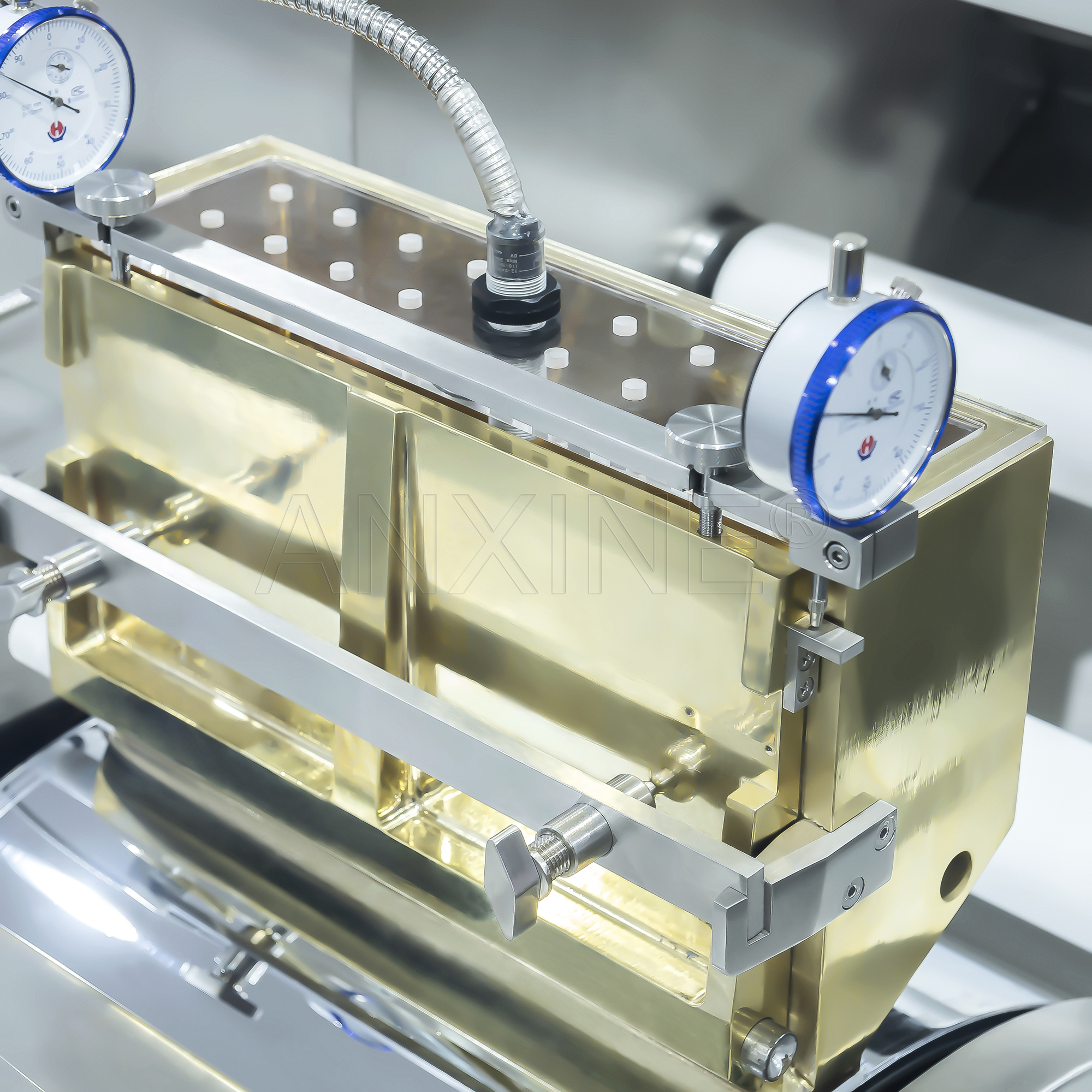

- Accurate drug filling system: One of the most outstanding features of the machine is its highly accurate drug filling mechanism, which can achieve a filling accuracy of less than 2%, ensuring the dosage consistency of each unit product.

- Environmentally friendly water cooling system: The machine is equipped with a complex water cooling system, which is designed to eliminate the heat that may be generated during the production process and completely avoid air pollution, reflecting its commitment to environmental responsibility.

- High capsule packaging accuracy: The machine also performs well in capsule packaging, achieving an accuracy rate of up to 98%, which greatly reduces the number of defective products and improves the quality of the final product.

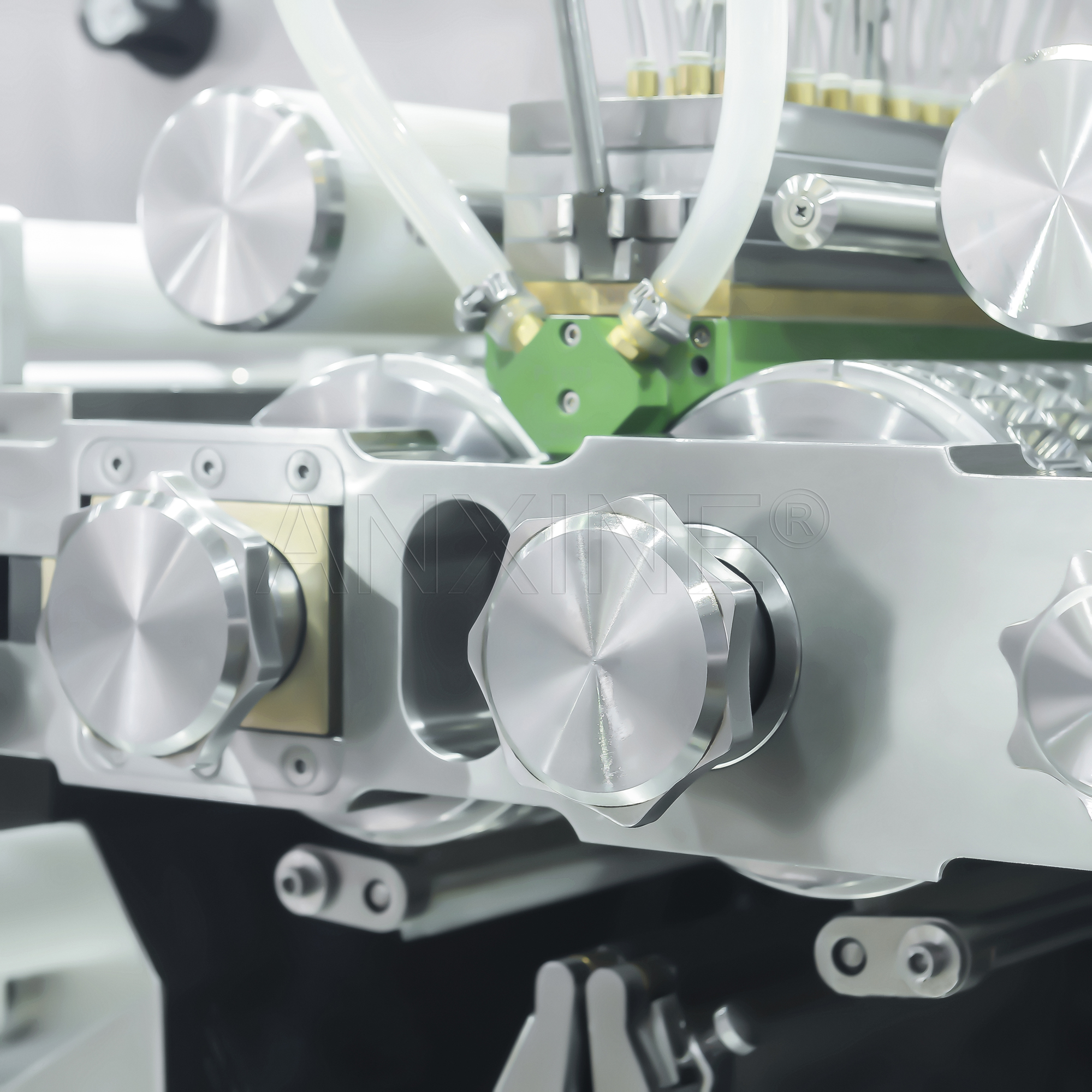

- Leading lubrication technology: The use of advanced gelatin belt lubrication technology is a highlight of the machine, which effectively reduces the use of lubricating oil and simplifies the capsule cleaning process, making the entire production process more efficient and clean.

- Premium Materials and Long-Life Design: The use of high-quality aerospace alloy materials to build optimized molds is a major advantage of this equipment. This choice ensures a long service life and maintains stable performance even under intensive working conditions.

Specifications

| Model | ASE-200C |

|---|---|

| Mould Rotational Speed | 0-5 rpm (Stepless frequency speed control) |

| Control System | Omron PLC + Weinview touch screen |

| Capacity | Approximately 48,600 pills/hr for #12 Oval |

| Supplying Volume | 0-2ml per single-pillar stopper |

| Pillar Quantity | 12 |

| Glue Cooling | Water cooling at approximately 18℃ |

| Power | 7 kW |

| Dimensions | 2,100×1,100×1,800 mm |

| Weight | 980 kg |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288