Continuous Induction Sealing Machine LGYF

Continuous Induction Sealing Machine LGYF

Welcome to the online store of Anxine Pharmaceuticals. We are proud to introduce the LGYF air-cooled continuous electromagnetic induction sealer, which is carefully built by a professional team. This equipment is manufactured based on advanced electromagnetic induction heating technology and is designed to provide high-quality sealing solutions for industries such as medicine, pesticides, non-staple foods, health drinks, cosmetics and chemicals, ensuring the best sealing effect of non-metallic containers such as plastic bottles and glass bottles, and meeting the needs of anti-counterfeiting and anti-theft.

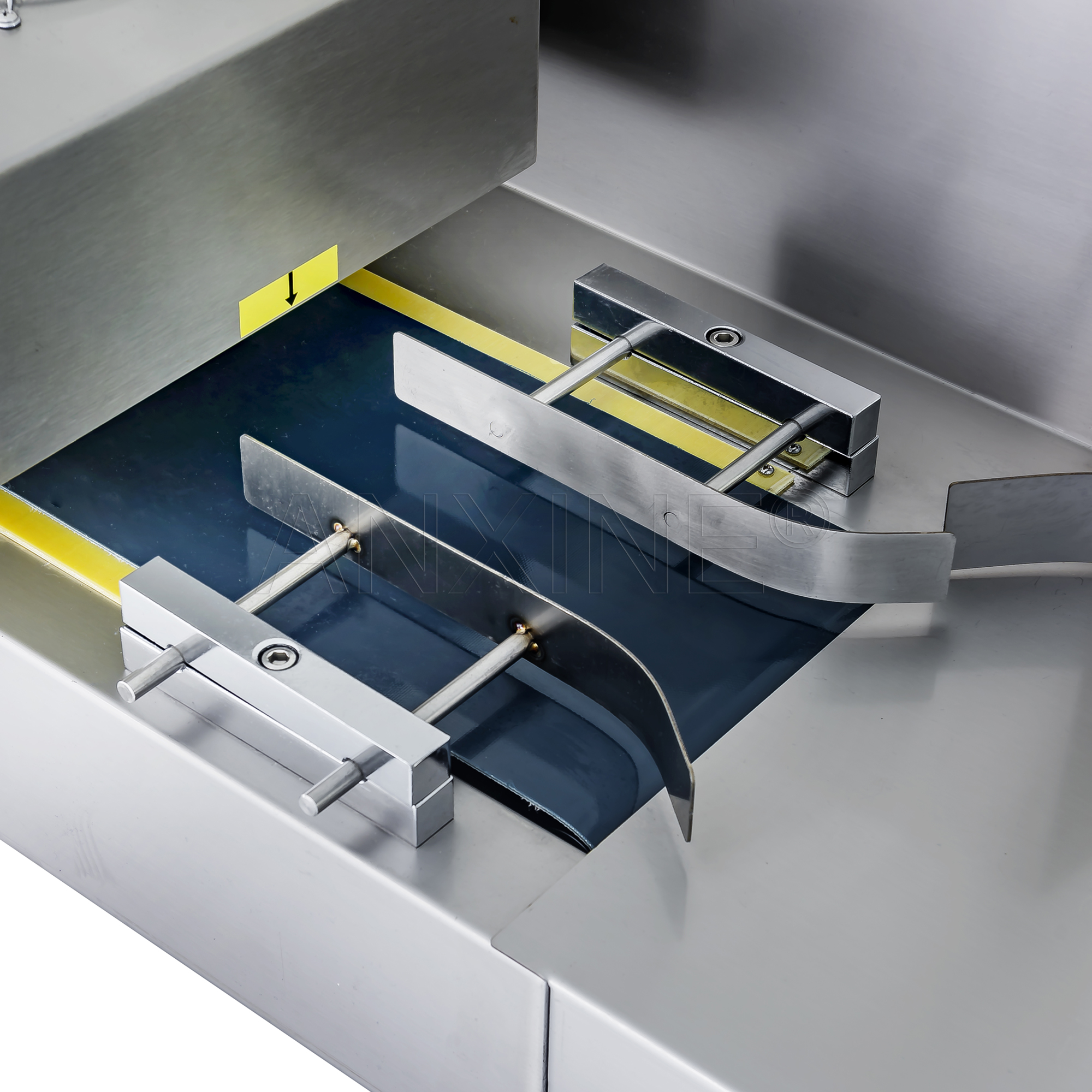

LGYF adopts internationally leading heating technology and imported key electronic components, combined with years of production experience and continuous exploration and improvement, to achieve a major breakthrough in sealing range, machine performance stability and work efficiency. This sealer is not only suitable for the ideal sealing quality and efficiency of large and small diameter bottles, but also when the machine fails, the conveyor belt will automatically stop working to isolate the sealed and unsealed products, ensuring the consistency of product quality. In addition, it also has the function of electronic stepless speed regulation conveyor belt, adjustable height sensor head and real-time monitoring of working voltage and current, so as to adapt to different sealing requirements and maintain stable sealing quality.

Description

The LGYF continuous induction sealing machines utilize the electromagnetic induction principle to instantly generate high heat, melting aluminum foil and sealing it to the bung hole. These machines serve a dual purpose: extending the preservation time and ensuring wet-proof, leak-proof, and mildew-proof packaging. They are now widely used in industries such as pharmaceuticals, pesticides, lubricants, and cosmetics.

Highlighted Features

- Wide range of sealing applicability: It can handle different sizes of bottle mouths, from φ20mm to φ50mm (optimal diameter φ30mm to φ50mm), and supports bottles with a height of 20 to 200mm.

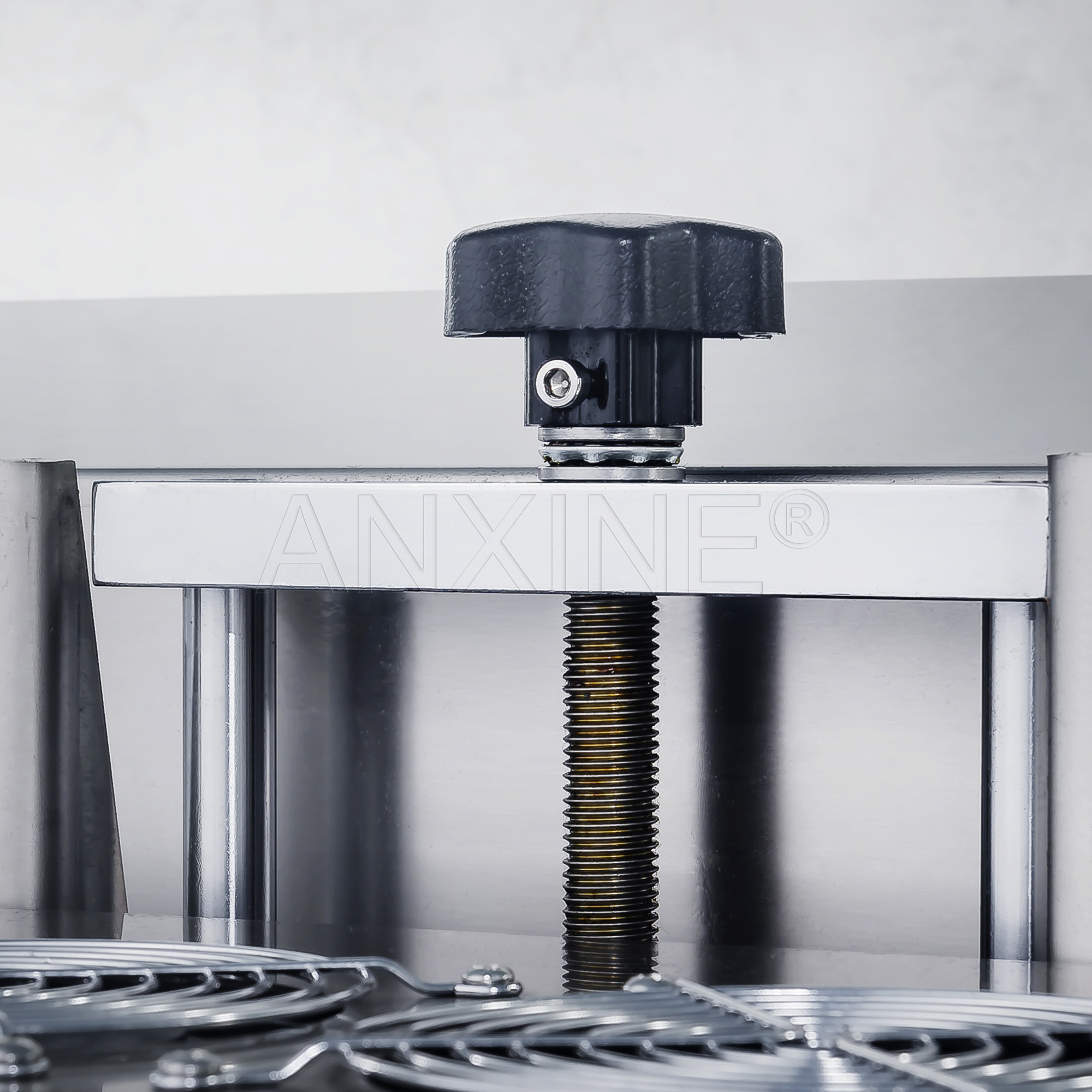

- Intelligent protection mechanism: Built-in overcurrent, overvoltage and overheating protection functions to ensure the safe operation of the equipment.

- Flexible speed control: Equipped with an electronic continuously variable conveyor belt, the speed can be adjusted according to actual needs to ensure the best sealing effect.

- Height-adjustable sensor head: Two-stage lifting design, suitable for sealing items within the height range of 20 to 300mm.

- Intuitive operation interface: Provides power meter and sealing current meter to facilitate users to adjust parameters according to actual conditions

Specifications

| Model | LGYF-1500A | LGYF-2000AX |

|---|---|---|

| Sealing Diameter | φ20mm~φ50mm(Optimum Diameterφ30mm~φ50mm) | φ20mm~φ130mm(Optimum Diameterφ30mm~φ120mm) |

| Height of Bottle | 20~200mm | 40~300mm |

| Conveying Diameter | ≤¢200mm | ≤¢200mm |

| Sealing Speed | 3~10m/min (Size of bottle mouth, material, sealing film) | 2~12m/min (Size of bottle mouth, material, sealing film) |

| Conveyor Table Load-bearing Load | ≤ 20kg | ≤ 20kg |

| Input Power | AC220V±10%,50Hz | AC220V±10%,50Hz |

| Weight | 38kg | 40kg |

| Dimensions | 1,150 × 480 × 400 mm | 1,150 × 600 × 400 mm |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288