Automatic Bottle Capping Machine PBX-160

Automatic High-Speed Efficient and Reliable Bottle Capping Machine PBX-160

The PBX-160 High-Speed Capping Machine is an advanced and versatile solution designed to efficiently secure bottle caps, capable of functioning as a standalone unit or seamlessly integrating with other equipment such as bottle unscramblers, sheet counting machines, paper plugging machines, and sealing and labeling machines to form a comprehensive production line. Engineered for precision and reliability, this machine adheres to strict pharmaceutical GMP (Good Manufacturing Practice) standards, ensuring high-quality output suitable for industries that demand stringent quality controls.

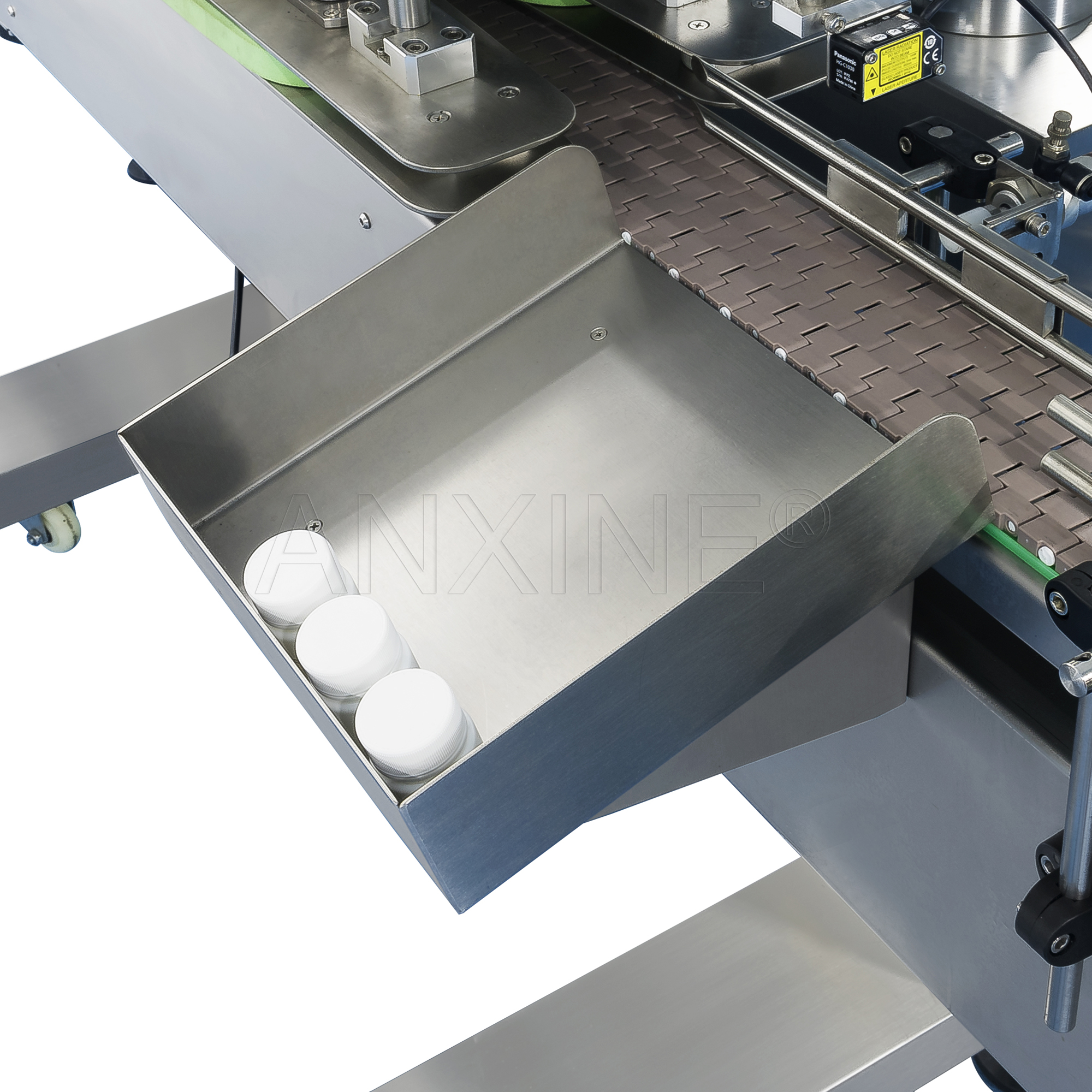

Designed specifically for the task of screwing on bottle caps, the PBX-160 features an innovative mechanism utilizing two synchronized belts that clamp and convey container bodies while three groups of high-elastic rubber wheels firmly grip and apply the caps. This design allows the machine to handle a diverse array of bottle shapes—including round, rectangular, and irregular—without the need for changing spare parts, thereby enhancing operational flexibility and efficiency. Its ability to maintain consistent torque application guarantees a reliable seal, making it an indispensable asset for manufacturers seeking to optimize their packaging processes while complying with industry regulations. The PBX-160 not only streamlines production but also ensures product integrity and consumer safety through its robust and adaptable performance.

Description

The PBX-160 High-Speed Capping Machine is an advanced solution for securing bottle caps efficiently. It can function independently or integrate with other equipment like bottle unscramblers, sheet counting machines, paper plugging machines, and sealing and labeling machines to create a complete production line.

The PBX-160 is ideal for companies seeking an efficient and reliable capping solution, supporting high-speed production demands while maintaining product quality and compliance.

Highlighted Features

- Versatile Bottle Compatibility: Easily adjustable to fit different bottle types and sizes.

- High-Speed Operation: Capable of capping up to 160 bottles per minute.

- GMP Compliance: Meets stringent pharmaceutical industry standards.

- Flexible Integration: Can operate as a standalone unit or within a complete production line.

- User-Friendly Adjustments: Simple adjustments for belts and wheels without needing spare parts.

- Durable and Reliable: Built for consistent performance and long-term use.

Specifications

| Model | PBX-160 |

|---|---|

| Maximum Capacity | Up to 160 bottles/minute |

| Cap Size Range | Diameter 19-65 mm |

| Bottle Size Range | 15-250 ml |

| Voltage | AC220V, 50Hz, single phase |

| Power | 2500 W |

| Dimensions | 2,600 x 1,100 x 2,000 mm |

| Weight | 580 kg (with conveyor) |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288