Semi-Automatic Bottle Capping Machine CDX-450

Semi-Automatic Bottle Capping Machine CDX-450

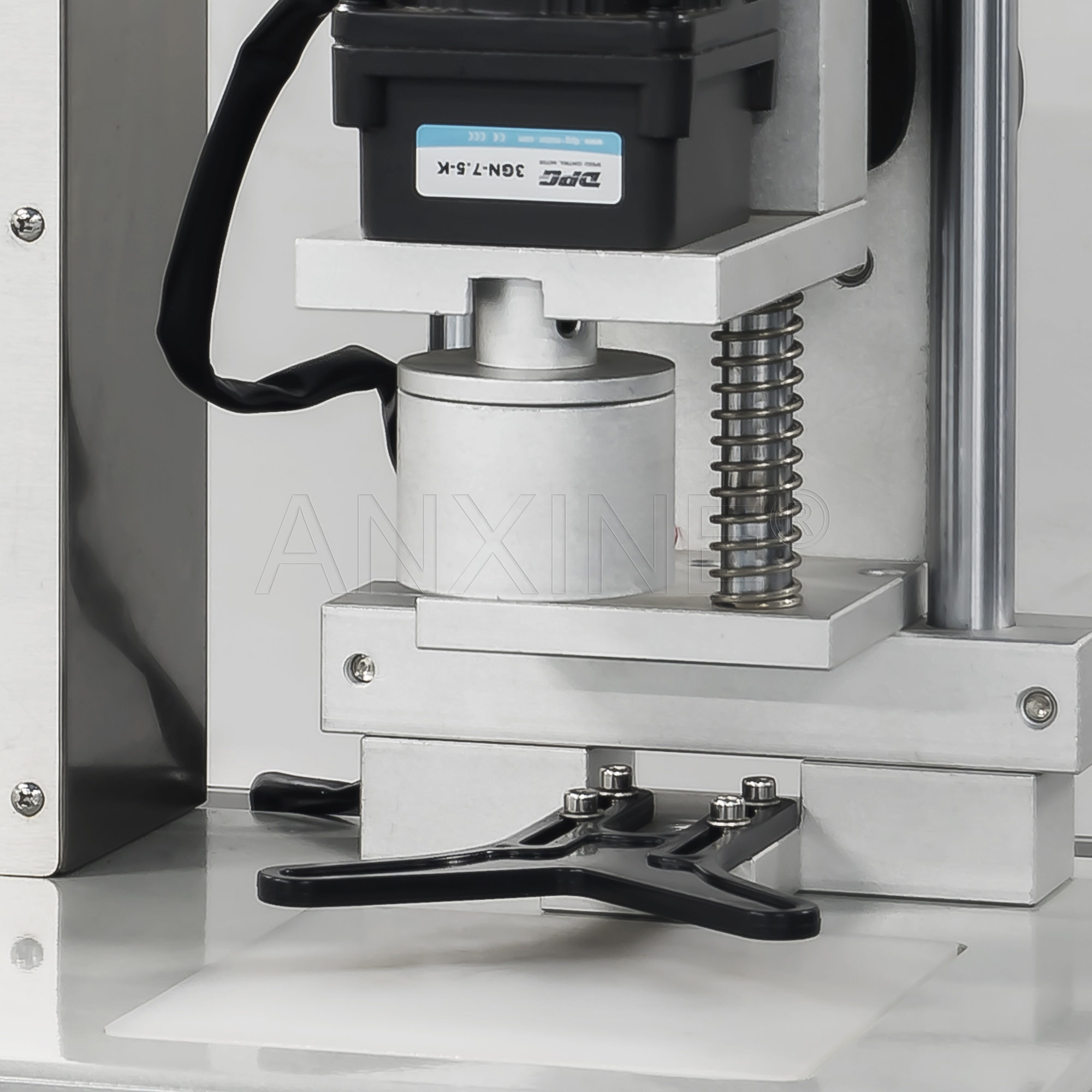

The CDX-450 semi-automatic capping machine is an efficient solution designed to meet the needs of small and medium-volume production in industries such as pharmaceuticals, health products, cosmetics and chemicals. As a desktop device, it not only has a beautiful appearance and compact design, but also provides an affordable option, especially for small businesses or laboratories that need to flexibly deal with different bottled products.

This machine combines stable and reliable performance with simple operation to ensure consistency and accuracy of each capping operation. With a low-pressure control system, the CDX-450 not only ensures the safety of operators, but also reduces the potential safety hazards caused by high-pressure environments. Its simple structure and easy adjustment allow users to quickly adapt to bottle caps of different diameters (20mm to 50mm) and bottles of various heights (80mm to 220mm, customizable below 80mm), thereby improving work efficiency and reducing the learning curve.

In terms of daily maintenance, the CDX-450 also performs well. It only requires regular lubrication of all moving parts and checking for loose parts or damaged power cords. This low maintenance requirement means lower costs in the long term while also extending the life of the equipment.

Description

The CDX-450 is designed for securely tightening screw pattern flat head plastic caps, making it ideal for a variety of applications including oil barrels, mineral water bottles, medicine bottles, cosmetics, and beverages. It is suitable for pharmaceutical, chemical, food industries, hospitals, research units, and laboratories for trial production and small batch production. Customization is available for special cap specifications based on diameter and height.

Highlighted Features

- Simple design: CDX-450 has a simple yet professional appearance, which can be easily integrated into any working environment.

- Stable and reliable performance: Low pressure control ensures the safety and stability of the equipment and reduces the possibility of failure.

- Flexible application range: It is suitable for bottle caps with diameters of 20mm to 50mm, and supports bottles with heights of 80mm to 220mm (customizable below 80mm), which can meet a wide range of application needs.

- Easy maintenance: Regularly adding lubricants and checking the tightness of components can keep it in good operating condition, reducing the cost of long-term use.

- Convenient operation: Through simple installation and debugging steps, accurate capping operations can be achieved, and no complicated training is required to get started.

Specifications

| Model | CDX-450 |

|---|---|

| Caps Diameter | Φ20mm~Φ50mm |

| Bottles Height | 80mm~220mm (customizable for heights below 80mm) |

| Power Supply | AC220V±10%, 50Hz; 110V, 60Hz |

| Dimension | 520 x 300 x 530 mm |

| Weight | 32 kg |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288