Big Volume CH Type Powder Mixer Powder Blender

Big Volume CH Type Powder Mixer Powder Blender CH100 - CH500

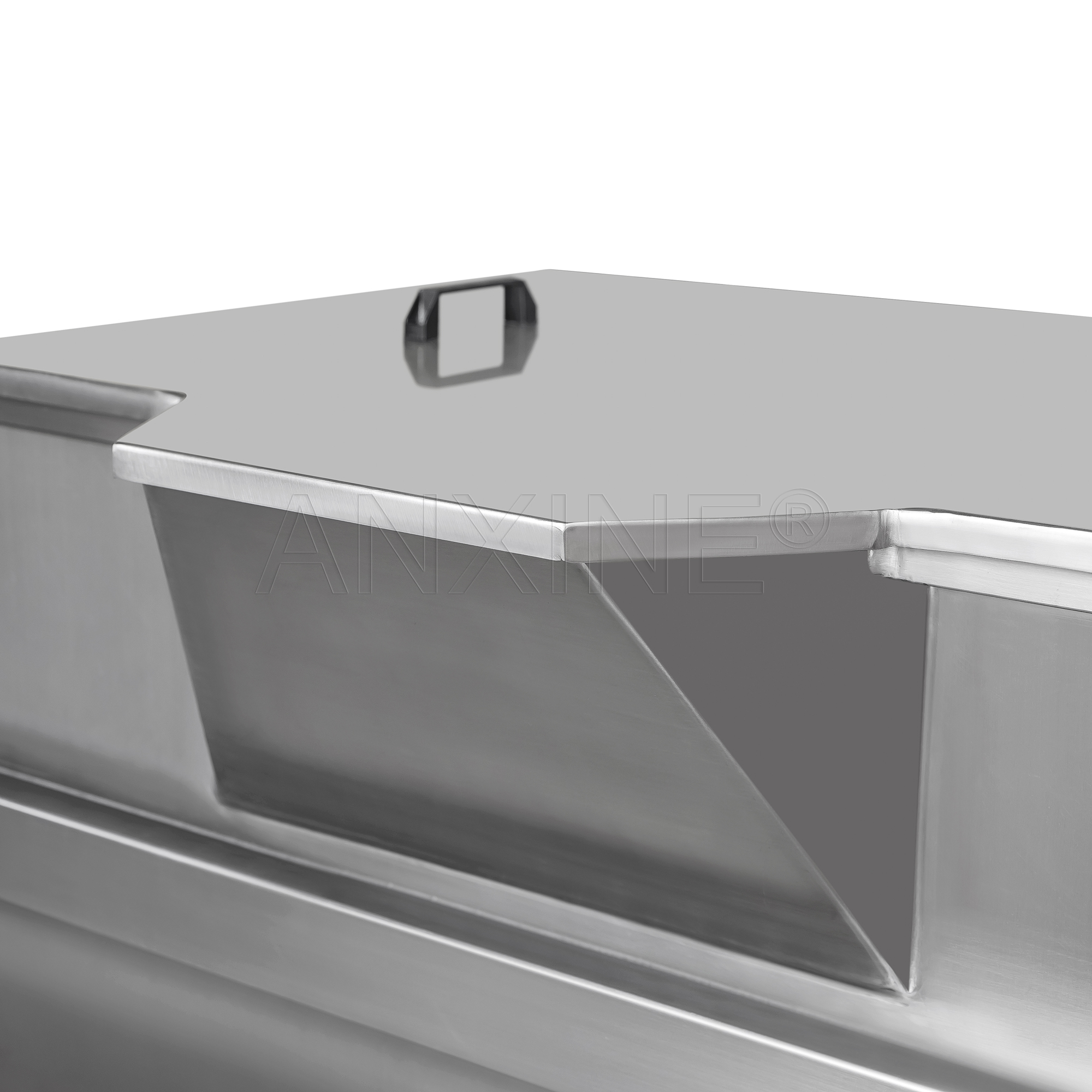

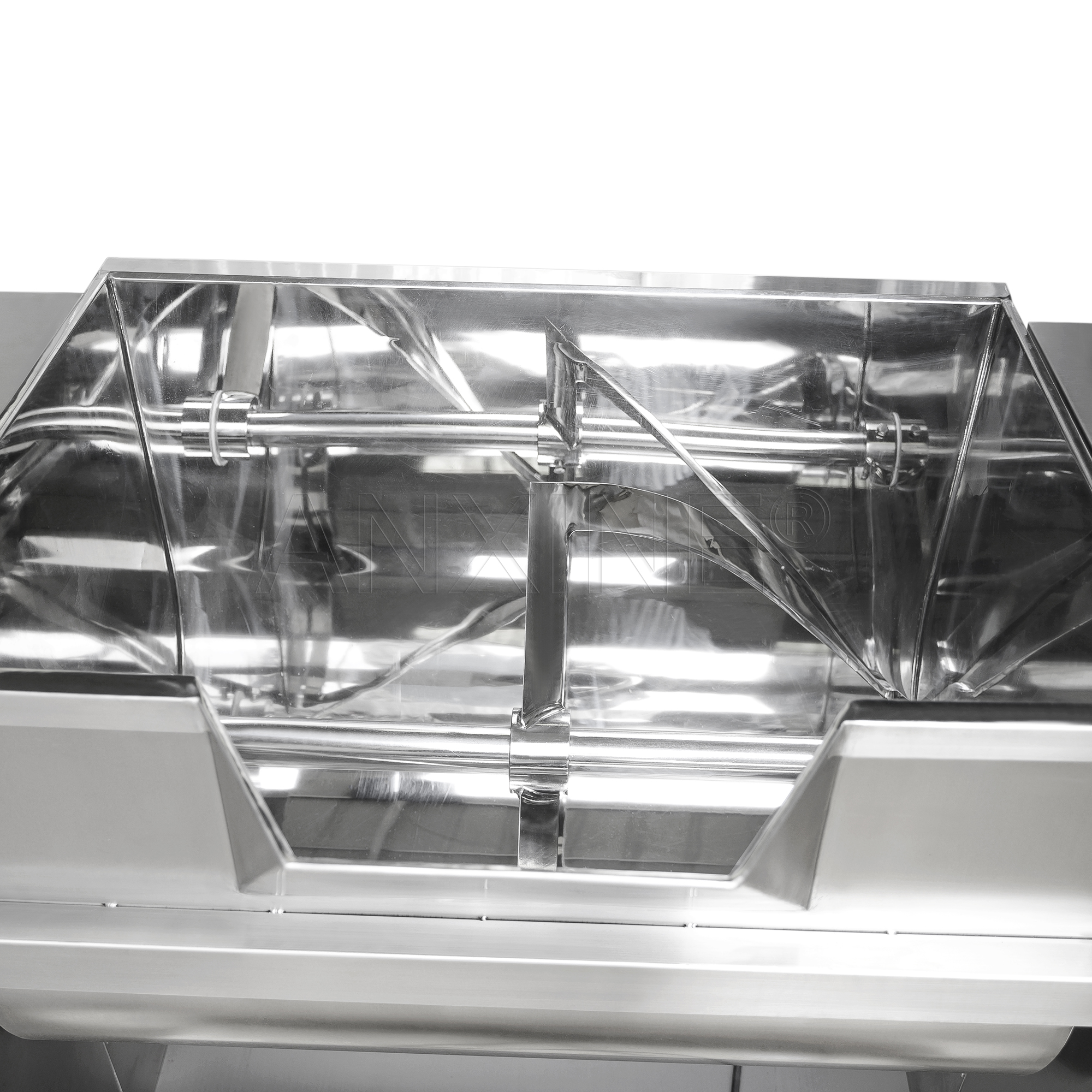

Powder Mixer CH-50 to CH-500 series are high-efficiency mixing equipment specially designed for the pharmaceutical, chemical and food industries. They are made of stainless steel to ensure hygienic standards and corrosion resistance, while complying with GMP requirements. This series of products uses a motor-driven reducer to drive the main shaft to rotate the blades, achieving continuous rolling and uniform mixing of materials in the hopper.

The two-way operation mode significantly improves the mixing efficiency and product quality consistency. The compact design saves space, and the intelligent control panel simplifies the operation process and provides safe and reliable operation. It is environmentally friendly and energy-saving, reducing long-term operating costs. Anxine Pharmaceuticals also provides personalized customized services to meet the special needs of different customers.

In general, the CH-50 to CH-500 series are an ideal choice that combines efficiency, convenience and environmental protection, and are suitable for mixing and processing of various dry powder and granular materials.

Description

The CH Type Powder Mixer is designed for efficient mixing of dry or wet powdered materials, primarily used in the pharmaceutical industry, but also applicable in chemical and food industries.

Highlighted Features

- Compact design, space saving: The CH-50 to CH-500 powder mixer series have a compact and optimized design, suitable for various working environments, especially laboratories and production workshops with limited space. This design not only facilitates installation, but also helps optimize material flow paths and improve production efficiency.

- Efficient and uniform mixing effect: The mixer drives the main shaft to rotate the blades through the motor-driven reducer, so that the materials continue to roll in the hopper and are fully mixed. This process ensures an even distribution between materials and avoids stratification, thus achieving high-quality mixing results.

- Personalized customization services: Anxine Pharmaceuticals also provides services for customizing mixers according to customer needs, including but not limited to different capacity selections, applications of special materials, additional functions (such as automatic feeding/discharging systems), etc., to meet specific requirements. special requirements of the industry.

- Strong technical support and service guarantee: Anxine Pharmaceuticals provides customers with a full range of technical support and after-sales services, from pre-sales consultation to after-sales maintenance, ensuring that customers receive the best experience and support throughout the entire use cycle. A professional team is always ready to resolve any issues that may arise, ensuring the equipment is always in top working order.

Specifications

| Model | CH-50 | CH-100 | CH-150 | CH-200 | CH-500 |

|---|---|---|---|---|---|

| Volume | 50L | 100L | 150L | 200L | 500L |

| Main Motor Power | 1.1 kW | 2.2 kW | 3 kW | 4 kW | 7.5 kW |

| Discharging Motor Power | 0.75 kW | 0.75 kW | 0.75 kW | 0.75 kW | 1.5 kW |

| Speed | 24 r/min | 24 r/min | 24 r/min | 24 r/min | 24 r/min |

| Dimensions | 980x425x820mm | 1,280x440x900mm | 1,590x600x1,075mm | 1,590x660x1,125mm | 2,350x800x1,300mm |

| Weight | 220 kg | 250 kg | 550 kg | 600 kg | 680 kg |

| Dimensions | 2,300x910x2,050mm | 2,800×1,000×2,280mm | 3,000×1,100×3,100mm | 3,200×1,200×3,350mm | 3,400×1,300×3,550mm |

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288